These 50-plus-year-old sporters are prime candidates for scope attachment problems.

I never had any intention to write anything about scope mounting. Nothing. I avoid it like the 27th mutation of the COVID-19 virus. Why? Because there have been countless articles published over the years dealing with the attachment of scopes, now called “optics,” to rifles. Some have been good, some not so much. Thus, most folks are highly opinionated on the subject. That is never good.

Times change, however. There appears to be a growing interest in some places to collect and shoot pre-1960 or so sporting rifles. If scopes are attached, they too must be from the proper time period. Targets are swinging steel plates at distances appropriate to the rifles. The pace is slow and it can’t become an equipment contest using the latest, most expensive gear. It is for the older scope mounts that these notes are written.

A rifle-supporting device of some type must be used when doing work involving scopes or mounts.

With old rifles in mind, I must quickly mention that over the years, there have been requests for me to do a column on Winchester Model 1905, 1907 and 1910 self-loading rifles. Never heard of them? Don’t feel alone. They were mainly seen in the deep woods of the northern tier of the U.S. and Canada, where rain and proximity to salt water have probably taken its toll.

While there is not enough interest for a column, several years ago, a fellow by the name of Leonard Speckin wrote a paperback book that included detailed text and photos on disassembly, reassembly and making the special tools needed for this. A couple of screwdrivers won’t do, believe me! This book has been reprinted as well as one by John Henwood. For anyone needing to replace a firing pin or buffer on one of these guns, the books are a godsend. They are available from Leonard Speckin, at lapeckin@4N6.com.

A Springfield ’03 receiver ring has been “aggressively polished.” The front base allows a piece of .010-inch shim stock to slide underneath.

Getting back to the other old rifles, shooters who are fairly new to the sport are appalled at the accuracy of these guns with groups of more than 1.5 inches at 100 yards from a scoped rifle! The barrel must be worn out, the muzzle damaged or the darn wood stock is warped. Older riflefolks just smile. They know that if the bedding is correct, quality ammunition is used, the bore looks good and the scope mount screws are tight, then that’s just the way it is.

This shows small dents and scratches on the scope tube from poorly-fitting import rings. The damage is small because the scope was on a rimfire rifle having no recoil.

On the other hand, however, maybe it isn’t. The foregoing things are important, but there is something else and it’s not the scope. It’s the scope attaching hardware. Articles never mention this, instead dwelling on pulling up screws to a certain inch-pound figure and recommending (or not), the use of a thread-locking compound. Since there are no moving parts, it has to be okay, right?

Directly after World War II, glass sights became the rage on virtually all rifles. Inexpensive imported scopes and mounts from Japan flooded the market. Bases and rings came in little “cardboard boxes” that would properly be called “bond paper.” The labels were light blue, green, red and yellow. The artwork looked like it belonged on a package containing fireworks. Bases, ring bottoms and ring tops were aluminum extrusions formed as bars several feet long, then, the parts cut-off to proper length. The rings were all the same – just one height.

Weaver ring bottom screws are 6x40 tpi (threads per inch) not 6x48. Old rifles will sometimes have 6x48s run in, which strip the threads when pulled tight.

It is not my intent to disparage extruded scope mounting hardware. Many such parts are made this way today. These imports, however, were bad. There was no machining done on the parts except drilling screw holes. Burrs were often left where the part was cut off the extrusion and the whole thing was covered with black paint. Their scopes were sold in every hardware store in the country. The cost of the rings and bases was about a dollar.

The hole spacing is incorrect on this import base. The front screw head is higher than the rear and angled toward the camera. The base looks like a Weaver, but has no part number and is painted.

Rifle owners knew nothing about attaching scopes so they just followed the printed instructions. Drill and tap the receiver (if needed), then turn in the screws tight. No thought was given to whether the rings were aligned with the bore or scope tube. If resistance occurred, some screws were loosened until the parts went together, then all were tightened again. This probably had a lot to do with the poor reputation acquired by the import scopes! Fortunately, these cheap mounts are easy to spot; just look for the flaking paint or dented and scratched scope tube where it has slid through the rings during recoil.

Experience shows the most efficient scope base is probably the integral Picatinny.

If all the foregoing isn’t enough reason to be rid of these things, there is one more. Sometimes hole spacing in the bases did not quite match standards. One hole in a base will then be wallowed out so the screw could be run in. Generally, this screw is covered by the ring so it isn’t visible. The base will not be tight if the rifle has been shot much. Replacing this whole mess with Weaver bases, rings and an old steel-tube Weaver K-4 scope will keep the rifle period correct. Smaller groups will probably result as well.

Enough of poorly made bases. What about properly-made bases that also cause misalignment and damage to the scope by the rings? This is by no means rare, especially concerning sporters made on military actions. The cause is simply too much polishing with too coarse of an abrasive when removing the military finish prior to bluing.

Bit sets containing the six most common Torx sizes (center row) are commonly available.

A photo shows a Springfield ’03A3 with a piece of .010-inch shim stock pushed under the left side of the front base clear up to the attaching screw. Note that the shim fits under about half of the base area. The rear half of the base will only accept a .003-inch shim. The base is only touching the receiver ring on the right-hand side. Can this affect the rifle’s grouping ability or cause scope damage? Given the heavy steel Redfield one-piece base, obviously not because the scope and mount have not been touched since installation more than 50 years ago. Two-piece bases, however, would allow the front base to drop down on the left side, pulling the ring out of alignment with the rear ring. Scope tube damage or movement during recoil of the 30-06 would result. Ring alignment will be covered in my next column. I hate to say it, but experience today is showing that the best scope base is an integral Picatinny!

A most important point involves ring and base screws. Trash the chewed-up slot heads and easily stripped-out Allen heads. Replace them with Torx head, drivers for which are now commonly available.

Kits containing several replaceable tips are sold for magnetic drivers by Harbor Freight and hobby shops. Torx screws are perfect for use with a torque wrench because there is no looseness or slippage in driver/screwhead contact.

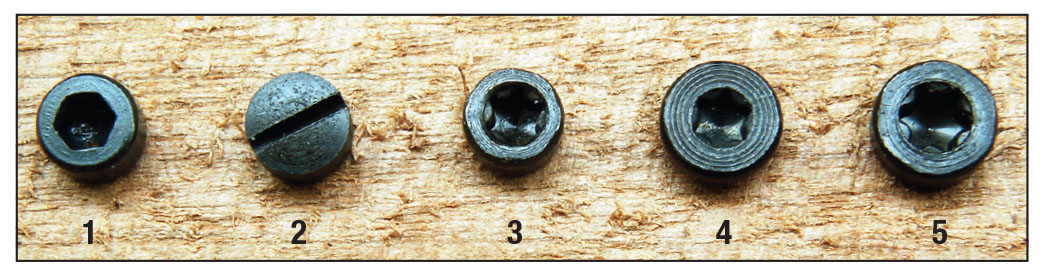

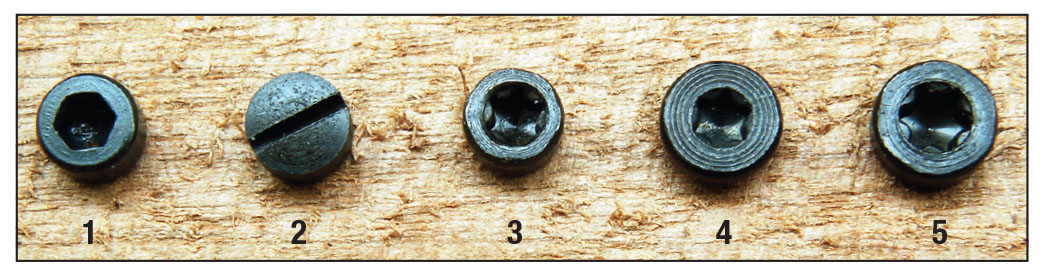

Screws included: (1) 6x48 tpi Allen head, (2) slot head, (3) T-10 Torx head, (4) 8x40 tpi T-10 Torx head and (5) 8x40 tpi T-15 Torx head.

Something that has been mentioned in previous columns, but is mandatory for scope and mount work is some type of holding fixture to position the rifle in a solid, upright position. It need not be expensive. Ordinary cleaning devices, usually called rifle vises, are satisfactory as long as they hold the gun without movement. Trying to balance a rifle with one hand on a rolled-up towel or sandbags will result in accidentally pushing tiny screws onto the floor where they will never be found. Screwdrivers will slip out of screw heads and poke holes in things that either break or bleed.