Light Gunsmithing

Falling Block Works Action

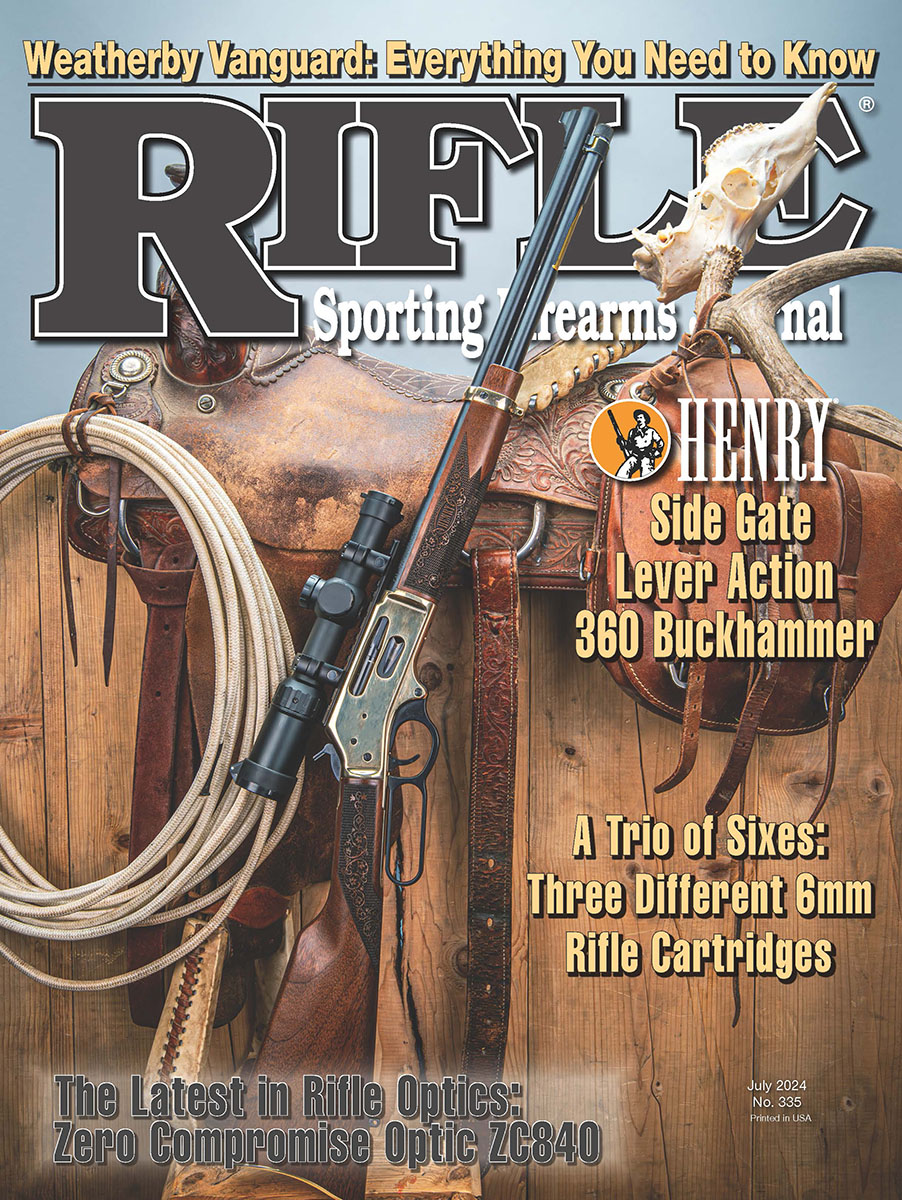

column By: Gil Sengel | July, 24

There is, however, one project that stands above all the rest. That is the custom-built rifle, and I mean custom built. Everything down to the smallest detail is specified by the future owner. Planning can go on intermittently for years.

The only problem with building a custom rifle is that few budgets are unlimited and the first order of business is finding an action. Bolt guns are the most popular. Mauser 98 and ’03 Springfield actions are available, as are poorly done sporters made from military rifles, which are no great loss if disassembled to get to the action. Single shots are most certainly in second place because of the Ruger No. 1 rifle and No. 3 carbine. These produce elegant modern custom

At least Ruger No. 1s are obtainable by anyone who can pay the freight. What if a custom rifle is wanted for an older rimmed round put up in an action with a

The chronicles reveal to us that in 1971, brothers Leo and Joseph Fix started a company supplying single-shot, falling-block actions only.

It would be logical to assume that these actions would be a copy of one of the old designs, but no! The new action was really two – the Model H and the Model Z. The design was entirely new and extremely simple, consisting of only seven major parts plus pins, screws and springs. Both actions used the same internal parts but were entirely different in the shape of the action body.

Model Z actions were of an entirely different shape, more like a Winchester single shot. However, the opening lever was a cross between the Model H and the Winchester. I have never seen a Model Z except in a photograph because when I first learned of the FBW actions (1974), the Model Z was no longer available. It had been replaced by the Model J. The Model H also disappeared within a few years.

The demise of the Models H and Z was said to be caused by the inability to set the trigger pull light enough. There may be something to this as the dozen or so Model H receivers I have seen all had pulls of 3 to 4 pounds. The action shown measures just under 3.5 pounds and there is no adjustment for weight of pull or overtravel. The sear engagement can be altered on all FBW actions by turning a set screw located in the hammer behind the spur. Of course, sear engagement has no effect on pull weight unless it is excessive or set so small that the trigger is dangerous.

At any rate, the Model J had a simpler trigger design than the others. The pull weight was lighter, though there was still no adjustment for weight or overtravel. The new trigger is pivoted at the top of the receiver rather than the bottom and the return spring is a coil-type rather than the previous torsion-type, so it can be changed to lighten the pull somewhat. The let-off of the two Model J actions shown is 2.5 pounds and they have not been altered.

The same thing happened with the next action announced, the Model L. It was the Model J simply scaled up to use a 1.125-inch barrel shank instead of 1 inch. Weight increased 30 percent to 44 ounces. A local shooter learned of the action and ordered one through the shop. Everyone who saw it was impressed. Here was an inexpensive action that could handle all the big British rounds up to 577 Nitro Express 3-inch, if loaded to only factory pressure. We promptly ordered two more and were informed none were available, but would be soon. Two years later, the order was returned, stating that the company had gone out of business. Oh well.

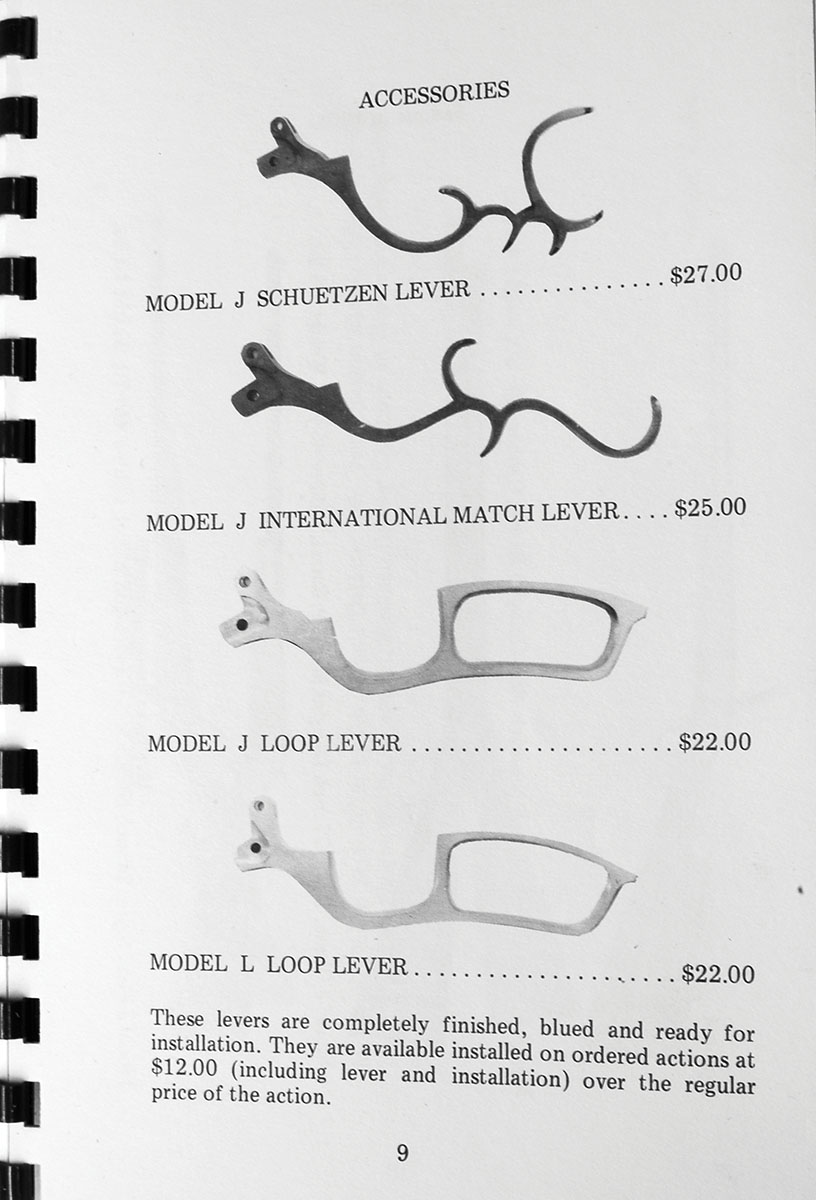

FBW’s last action, the Model S, was obtained as soon as it was announced. It’s the same as the Model J inside. The outside shape is similar to the Stevens 44 or 44½ but with higher sidewalls. Most notable is the longer receiver ring. This allows space for a .375-inch set screw to come up through the bottom and contact the barrel threads making a takedown rifle of sorts. Such is sometimes seen on target rifles of the very early 1900s. The Model S shown was ordered with a loop lever (see photo of the catalog page) for a project that obviously isn’t done yet. Still planning!

In conclusion, FBW actions are not common because hammer-fired falling blocks with a manual extractor doesn’t take well to low-mounted scopes. On the other hand, Models J, L and S with improved triggers are the pinnacle of such an action type. I can’t imagine any part breaking, but if disassembled (perhaps for bluing) reassembly is difficult. Long tapered slave pins will be needed to prevent damage. All parts fit so precisely that there is no looseness anywhere.

Six actions and four different levers were probably too much for a limited market to bear. Nevertheless, if a Model K with an improved trigger design and Model L were available today, it would make a lot of single-shot buffs mighty happy.