Composites Come of Age

A Long Way from the Nylon 66

feature By: Terry Wieland | September, 22

There are also many reasons to dislike them. They are noisy in the brush, have an annoying clanging sound when closing the bolt, are icy in cold weather, and the surface is alternately slippery, scratchy, or reflective.

When composite stocks first appeared – plastic, fiberglass, Kevlar and others with unpronounceable names – the cons far outweighed the pros. At least, they did to me. One quality not mentioned on either list above is appearance; another is flexibility – the capacity to be altered to fit. When I first began using composite stocks – reluctantly, against my will – in the 1990s, I found them to be ugly, noisy, clunky and I spent entirely too much time coming up with excuses for even having one in my possession.

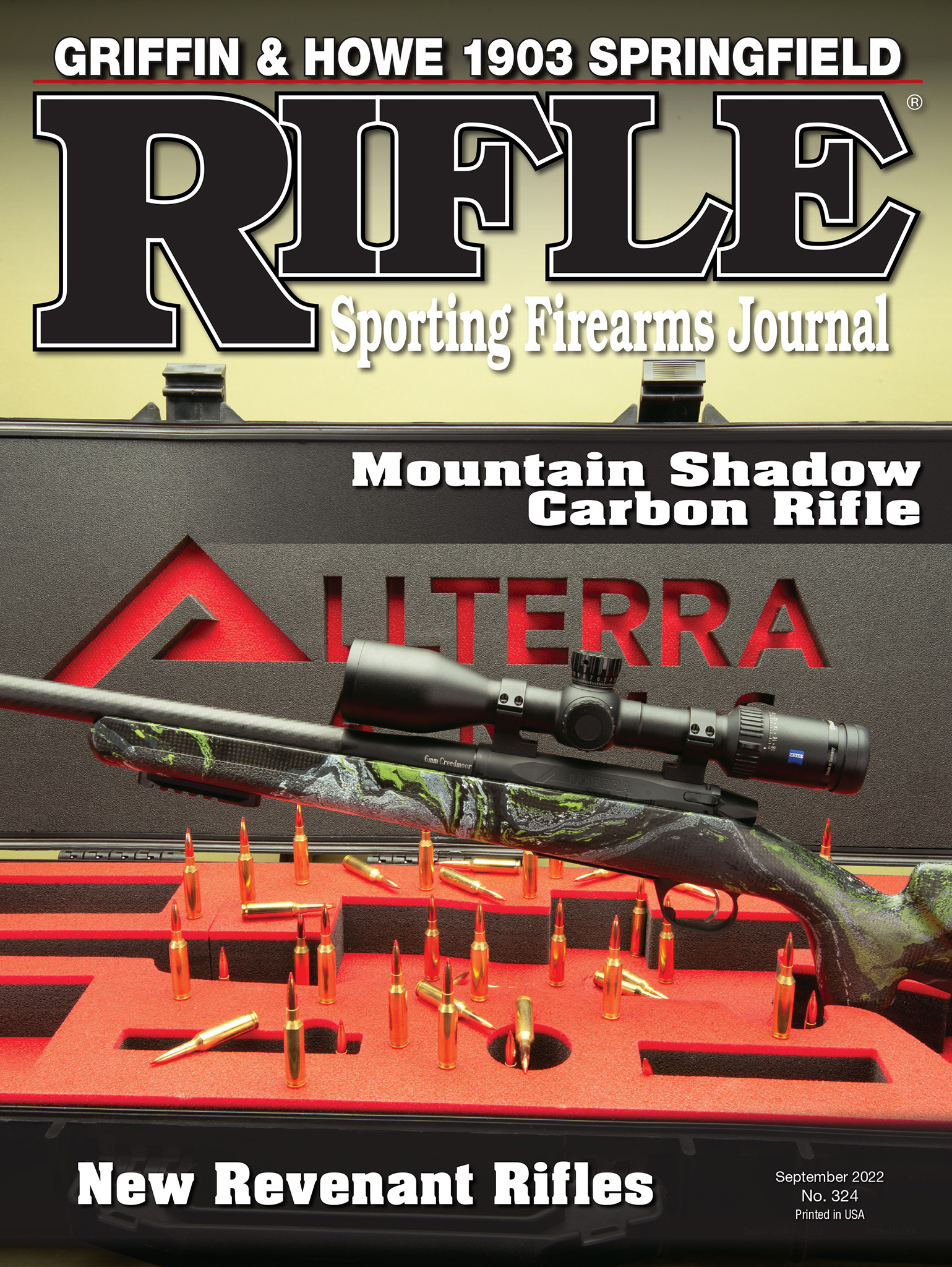

Well, times have changed, composite stocks have changed with them, and many (but not all) of the objections above have been overcome. This applies to both factory rifles and aftermarket stocks. Many of those ugly ducklings have turned into swans.

The rifle is a Bergara bolt action in .308 Winchester – a well-regarded maker in a highly-esteemed caliber. The rifle delivered excellent results, particularly with Federal Gold Medal ammunition and 168-grain Sierra MatchKing bullets.

Because we now live in a world of myriad stock patterns, fitted to countless different rifles, the most sensible course is to look at some specific examples, starting with my very first encounter with what were known as “plastic” stocks in the 1960s. The Remington Nylon 66.

As the name suggests, the stock was actually made of nylon, not plastic, and it was introduced in 1959. It was a semiauto .22 with racy “space age” lines, dressed up with diamond inlays and sporting a handguard. The stock was a shiny brownish-red intended to resemble walnut and it was not altogether unattractive. In the years since, I’ve handled a couple. They did not weather well. Chipped and scratched, the stock looked like a beat-up kid’s toy, and in fact, felt like something from a toy store. This, however, was not unusual for many guns in that era, as manufacturers experimented with non-ferrous alloys and synthetic alternatives to increasingly expensive walnut.

Another alternative, tried by Remington about the same time, was laminates. These first appeared commercially on the Model 600 carbine, although Germany had used laminates on K98s late in the war when it became difficult to get walnut. Many of these Mausers found their way to the U.S., so the concept was familiar.

Like the Nylon 66, the Remington 600 was another futuristic effort, but this time chambered for cartridges with serious recoil, like the .350 Remington Magnum. There was plastic used as well, in the form of a ventilated rib, which drew some rude references. The stock was panned, not for its strength, but its appearance. The laminations, of walnut and birch, beech, or maple, were quite thick and gave the stock the look of a piece of misbegotten Scandinavian furniture. It was strong, stable, held up well, and felt like a real wooden stock – which of course it was – but laminates tend to be heavy and nothing could overcome its appearance.

In retrospect, it seems to me the turning point with synthetic stocks came when they stopped trying to imitate walnut, in looks and feel, and began playing to their own strengths. For example, I had a very early Weatherby Fibermark (Mark V) with a synthetic stock made by, I believe, McMillan. It aped the distinctive shape of a Mark V stock, but trying to give dull black fiberglass the Marilyn Monroe look of a real Mark V is hopeless. The entire surface was rough as sandpaper, which gave a good grip but was hard on the cheek. As well, it was thicker than it needed to be everywhere, and there was always that annoying clang.

Another rifle, this one a Kenny Jarrett (an early proponent of synthetics for stability and accuracy) was made by Bell and Carlson. It had moulded-in “checkering” that gave no improvement in the grip and made the stock look like it came from the bargain counter at a toy store.

While a mould can be made to any shape or size, manufacturers seemed to choose a “one size fits all” approach that was, in fact, one size fits no one. There is almost no limit to the alterations that can be made to a wooden stock. The possibilities are endless, and all you really need are skilled hands and a file. Plus, it can be an on-going process, increasing this, slimming that, as you shoot it and discover what’s needed. Creating thousands of stock moulds to cover every possible permutation would be out of the question, and even if it were not, once you’ve moulded your stock, that’s it.

The AG Composites stock shown here has an adjustable comb, which is not unusual. As scopes are switched, the comb can be moved up and down to keep the eye aligned with the scope. Since the stock can be moulded with areas specifically designed to accept the mounting mechanism, it can be stronger than a similar fixture on a wood stock, and given a much greater range of movement.

But there are problems with a movable comb. They can be very uncomfortable, depending on the finish. A surface like sandpaper, combined with a hard-kicking rifle, is horrible. So is a comb that moves too easily. Just when settling in for the shot of a lifetime, it pops up or down, and the shooter is left struggling to adjust it as the seven-point elk disappears into the brush.

One rifle I had for testing had the comb so close to the bolt that it could not be removed. The comb had to be taken off completely to take out the bolt, and removing the comb required a suitable Allen key. There you are, climbing a mountainside in the snow, your barrel gets clogged, you try to clear it, drop the Allen key in the snow… Well, you get the picture. No problem on a range, punching paper, but potentially a huge problem in the real world of hunting.

The AG Composites comb is also close to the bolt, but has been inletted to allow easy removal – an excellent touch.

Blaser’s “Ultimate” stock for the R8, delightful in many ways, has a spring-loaded comb and a thumb-catch beside it. Easy to move? Absolutely. Easy to move accidentally? Also, absolutely.

Combs present another hazard in this age of facial hair. One’s beard can become caught in the cracks, which really gets your attention under recoil.

Before we leave the subject, conventional hunting stocks made of composites have been vastly improved over the years. The stock on Ruger’s Hawkeye “FTW Hunter” is an example. It has the lines and proportions of an American Classic stock, with only the buttpad adjustable, but the grip and forend are slim and comfortable, and the checkering is as sharp as anyone could wish.

My major interest in looking at it was to see just how usable it was – how ergonomic, user friendly and non-injurious. With composite stocks, especially from a maker like AG Composites, one assumes good workmanship, stability, CNC inletting and the like. Again, Burt Reynolds of the Top Gun Sportsman’s Club, who is more into long-range, tactical, and bench shooting than I, was my testing medium. He also did the shooting, as I was recovering from a slight shoulder injury.

Lest anyone think I’ve been completely won over to composite stocks, we come back to my earlier complaints about moulds. Most manufacturers offer a plethora of variations, colors, finishes, barrel channels, and forend profiles, but these are similar to the options offered on a car. Unless I read it wrong, there are limitations on what rifle actions can be accommodated, and that can be the critical factor. If I want a stock for the Remington 700, I’m in luck; if I have a super-accurate 6.5-.300 Weatherby Mark V, I might not be. The key phrase is “might not.”

Finally, we come to cost. To take AG Composites as an example, its base price is around $750. Compare that with having a custom walnut stock made by a good stockmaker, and composites win by several moon shots. With good walnut – and I would not pay for custom stockmaking on a piece of ho-hum wood – it is well into the thousands, and $10,000 is not unlikely.

In a way, however, we have been comparing apples and oranges. Since the Nylon 66 made its debut, rifles have gone in several radically different directions. Just as there used to be rifles I’d never dream of putting into a plastic stock, now there are rifles completely unsuited to anything but the highest of high-tech carbon fiber. The composite stocks of today are a world – no, several worlds – away from what they once were… and that annoying clang when I close the bolt? Gone. (Well, mostly.)

.jpg)