Notes on Barrels

Accuracy Through the Ages

feature By: Wayne van Zwoll | May, 24

Like flower buds in spring, groups suddenly blossom after a third shot, as if freed from unnatural constraints to explore the nether reaches of the target paper. My grin faded.

A final pair of Bergers bulged the hole to .23 inch. Still tidy. A welcome gift from a lightweight rifle. It was my first group with a carbon-fiber (CF) barrel from Proof Research.

Having grown up on target rifles with barrels the diameter of truck axles, I couldn’t fathom one-hole accuracy from a soda-straw barrel in a Styrofoam sleeve. The idea that such a barrel could even brook the Creedmoor’s 60,000 pounds per square inch seemed far-fetched.

A barrel’s first function is to bottle pressure. Improved black powder, then smokeless, prompted changes in barrel metal, from iron to mild steel. Jacketed bullets sent at high speed in rifled bores brought “ordnance steel” in 1903 Springfields. Winchester “nickel steel” was harder to machine but better resisted bore erosion. Chrome-molybdenum (CM) barrels were followed in the 1960s by rust-resistant stainless. A chrome component increased hardness; sulfur eased machining. Accurate barrels have been made of both CM and stainless, though barrelmaker John Krieger, points out benchrest shooters now lean to stainless. So does H-S Precision, whose cut-rifled barrels serve long-range shooters and industry test labs.

Barrels must have high tensile strength (measured by the force required to break a steel rod 1 inch in cross sectional area by pulling at both ends). While hardening steel typically increases tensile strength, it reduces elasticity, which is also important. A tensile rating of 100,000 pounds can’t save a brittle barrel. I have it on good report that barrel steel should score between 26 and 32 on the Rockwell C scale.

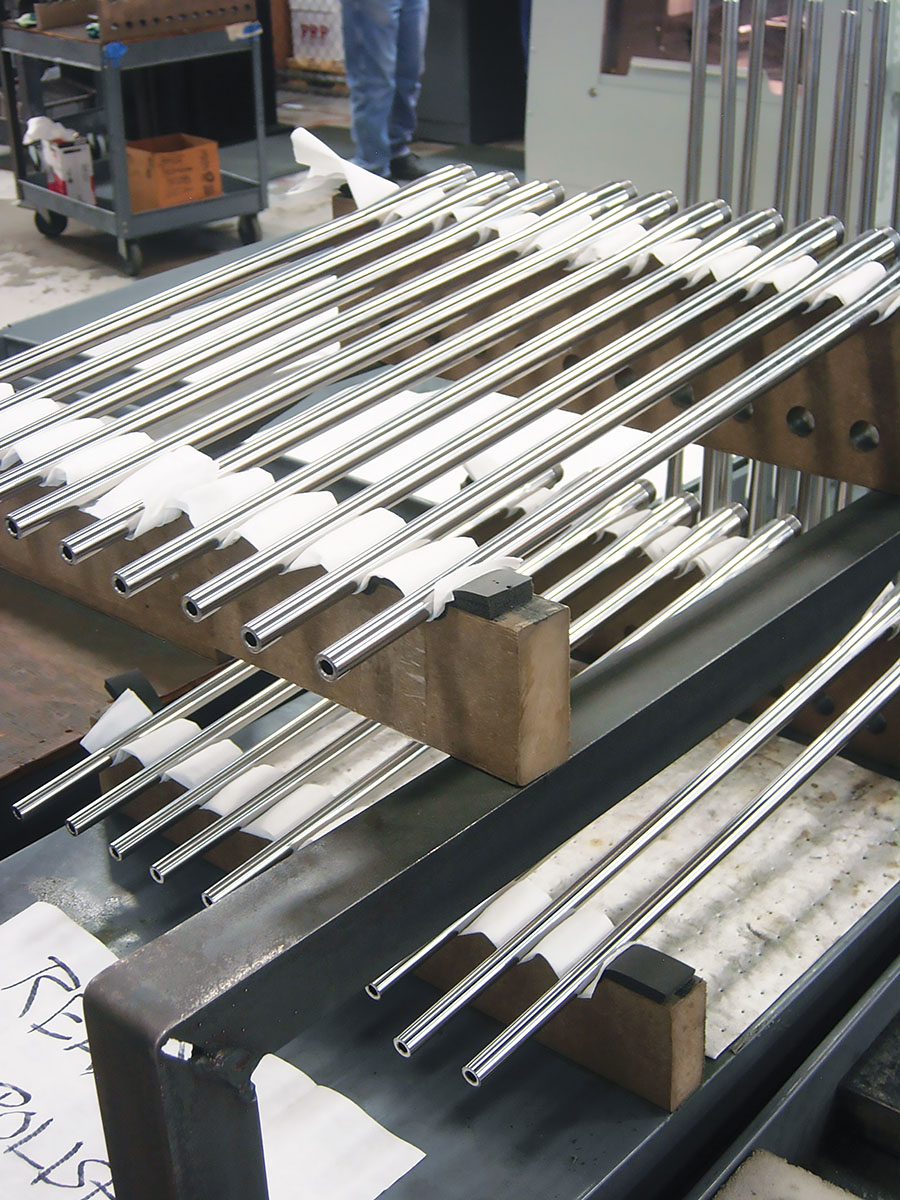

A deep-hole drill makes barrel blanks of steel bars. Traditionally, each bar is spun slowly about a stationary bit on a long tube with an oil groove. Bores are

John Krieger of Krieger Barrels concedes rifling with a single-point cutter is slow. “But it doesn’t stress the steel.” That’s important to benchrest shooters, who must nip quarter-minute groups. “They tell me eight of 10 barrels rifled with a single-point cutter are competitive,” John reports. “Button rifling might yield three.” Why? “A steel blank can vary in molecular structure along its length. As a cutter shaves so little material at each pass, it’s not as sensitive as a button to anomalies.” To cut grooves faster, armories use broaches – multiple cutters in stepped ranks. Broaching best suits handguns, “due to broach stretch in long barrels.”

Steve Dahlke apprenticed under John Krieger, then captained the Criterion barrel both men established. Since 1999, Criterion has produced button-rifled CM and stainless barrels for Weatherby and other riflemakers. Its barrels have also delivered record-setting accuracy in competition. Dan Lilja’s barrels are button-rifled too; he cites the uniform groove depth and smooth finish produced by the button.

Kenny Jarrett of Jarrett Rifles has built semi-custom rifles since 1992. Adopting benchrest accuracy standards, he met them with button-rifled Hart and Schneider barrels, then his own. Jarrett’s “Beanfield Rifles” were celebrated for their accuracy before long-range shooting was a trend. On the range outside his shop, I’ve seen his 30 magnum hunting rifles poke half-minute groups at 400 yards.

Hammer-forging, developed to make barrels for German MG 42 machine guns, “kneads” barrels about a hard mandrel, the rifling in reverse. Blanks enter the maw of the forge thick and short, to endure pummeling by thunderous blows that shake factory floors. They emerge slender and a little longer. While bores of hammered barrels are of finished dimensions and smooth, the process imparts stresses that aren’t removed from the steel in production line rifles.

Opinions on bore finish differ among riflemakers. Some contend that surface ripple of 10 to 20 micro-inches yields the best accuracy, that perfectly slick surfaces boost bore friction on bullets. A good example is the friction felt when pressing two glass plates together and then try to slide one off the other. Some riflemakers, including Kenny Jarrett, hand-lap bores with abrasive compound on lead plugs to polish out visible rifling marks. Lapping can also relieve tight spots. Bill Wiseman laps his cut-rifled barrels but said, “dimensional uniformity matters more than a smooth surface. Ordinary lapping removes only about .0002 from the bore surface, so can’t make up for careless rifling.” Krieger cut-rifled barrels are lapped to just under 16 micro-inches in the direction of bullet travel. Steve Dahlke laps Criterion barrels after stress-relieving.

There’s no compelling evidence that spin direction affects accuracy. Rifling with a right-hand twist is most common, though P-14 Enfield rifles and Colt revolvers have left-twist barrels. At extreme range, spindrift sends bullets in the direction of spin. It’s not a factor at normal hunting ranges. A proper spin rate is critical. It depends mainly on bullet length, secondarily on velocity. Long bullets at modest speed beg sharp spin. Short bullets launched fast excel with a slower twist. In 1879, Alfred George Greenhill came up with a formula to calculate the best twist rate for jacketed bullets: Required twist in all calibers equals 150 divided by the length of the bullet in calibers. It appeared in the British Textbook of Small Arms in 1929. Example: For a 130-grain, 270 bullet four calibers long (just over an inch), the correct twist would be 150/4=37.5. That’s in calibers; to get inches of travel per revolution, multiply 37.5 by .270. Answer: 10.4. Most barrels for the 270 Winchester are rifled with a twist rate of 1:10.

Sometimes non-standard twist gives the best results. While a 1:10 twist rate has long been recommended for .30-caliber cartridges, some shooters and riflemakers prefer 1:11 to serve a range of bullets. Echols likes it for 300 Winchester and 300 Weatherby Magnums. Preston Pritchett uses Krieger cut-rifled 308 barrels with a 1:11 twist.

Long bullets with very high ballistic coefficients have become the rage for shooters craving hits across townships. Many such missiles require steeper-than-standard rates of spin. But Echols insists most hunting bullets don’t. “I’ve used the 264 Winchester Magnum a lot and found it likes standard 1-in-9 twist for 129- to 140-grain game bullets. But shooters can be easily swayed by trends. One ordered a 1-in-7-twist for his 264 sporter. Another specified 1-in-12 rifling for a 450, even after I told him 1-in-16 was not only adequate but would reduce torque in recoil.”

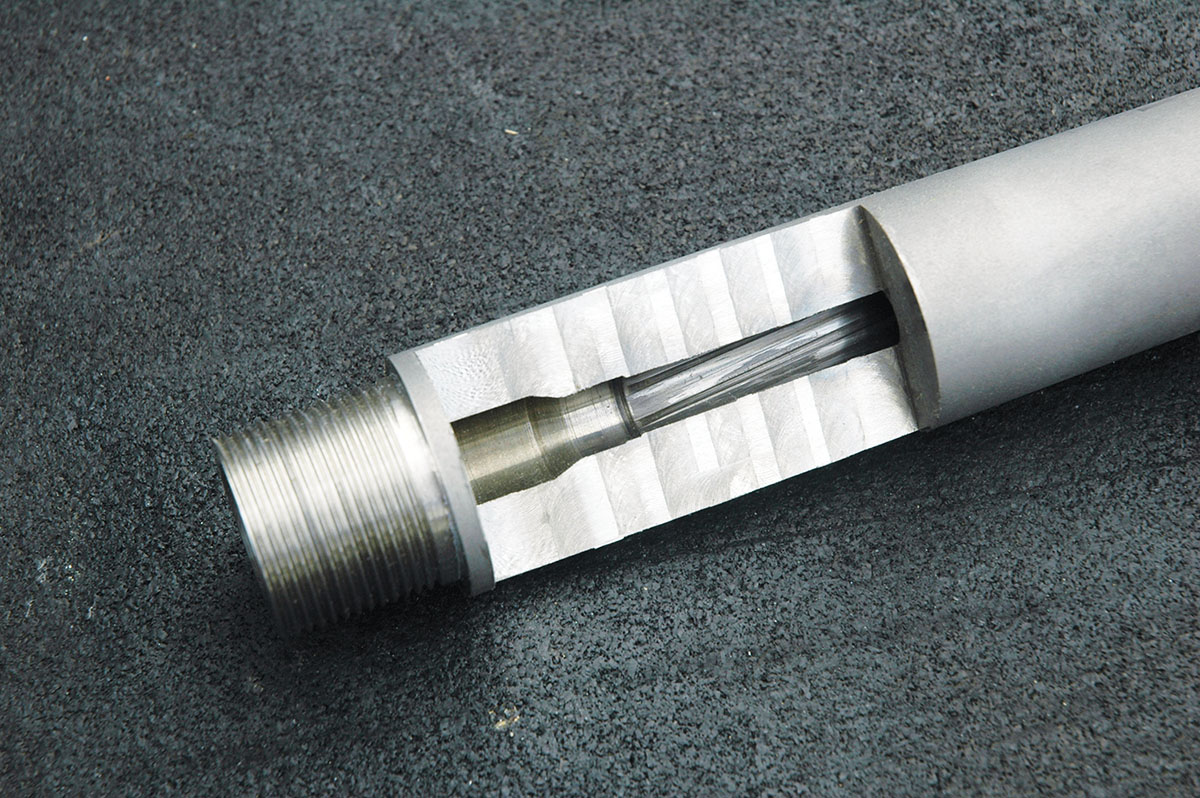

Accurate bullet flight starts in the barrel’s throat, an unrifled section of bore fronting the chamber. A long throat gives the bullet “a running start,” relieving pressure at the bullet’s launch. Roy Weatherby cut long throats to boost velocities without hiking pressures. Forward of the throat is the leade, the entry taper of the lands. Generally, 1½ or 2 degrees, leade angle can also affect pressure. Many shooters prefer parallel throats to the funnel-shaped throats of black-powder days. A parallel throat performs like a piston sleeve to guide the bullet. Ideally, each shank is a “slip fit.” But the throat must accommodate variations in bullet diameter without swaging shanks. In .30-caliber rifles, for example, John Krieger favors a .3085- to .3090-inch throat. Do long throats impair accuracy? Not when properly sized to the bullet, aligned with the bore’s axis and perfectly finished!

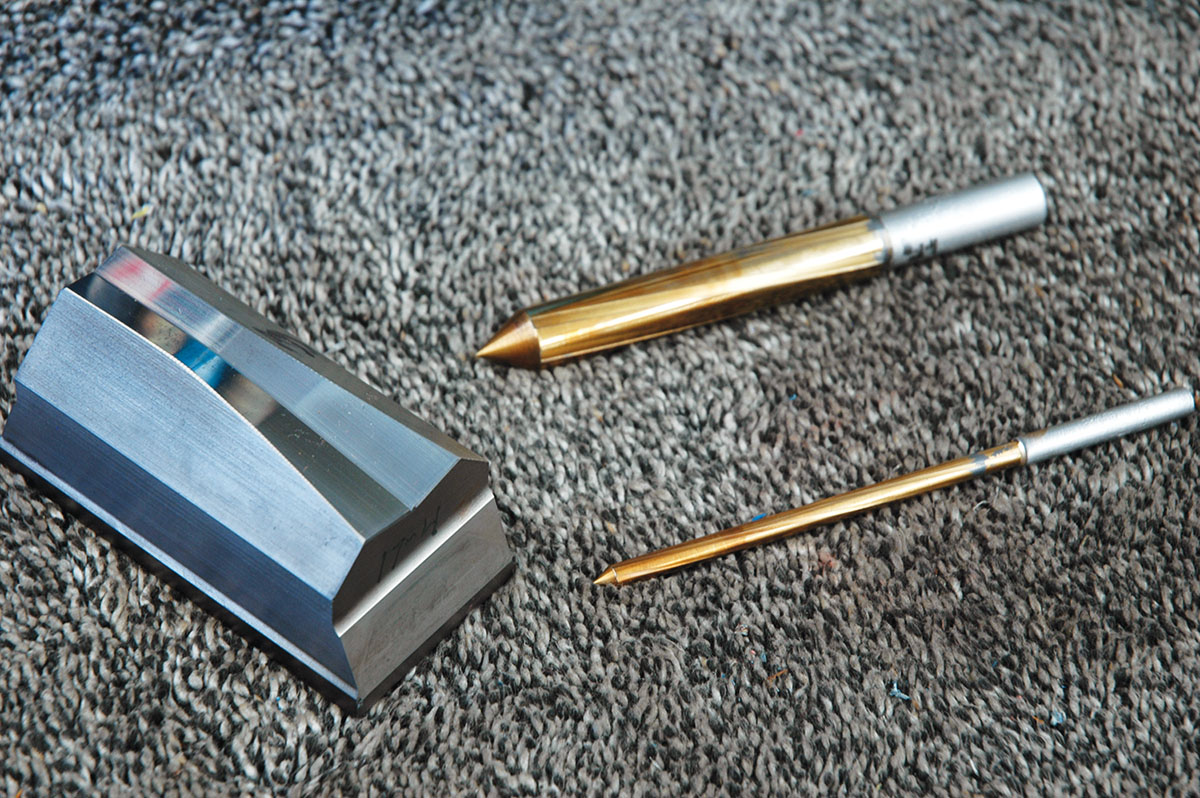

Crowning a barrel ensures bullets exit cleanly and squarely. A poorly finished crown, or a muzzle nick, allows gas to escape before a bullet’s base is free of the barrel, tipping the nose off its axis. While some muzzles are finished flat, or almost flat, radiused crowns are most common, and standard on rimfire rifles. I can’t say who declared a shallow 11-degree muzzle recess the ideal “target” crown; but it has become popular. The McMillan barrel that helped me to a state title with my Remington Model 37 prone rifle has it. On hunting rifles, I like a well-recessed muzzle to protect the barrel’s mouth when it is shoved onto a gritty pickup mat, noses from a scabbard to poke a mule’s muddy foreleg, or eats mountain rock after a stumble. The muzzles of Echols rifles have a step to an 11-degree slope. The mouth gets a light 60-degree chamfer.

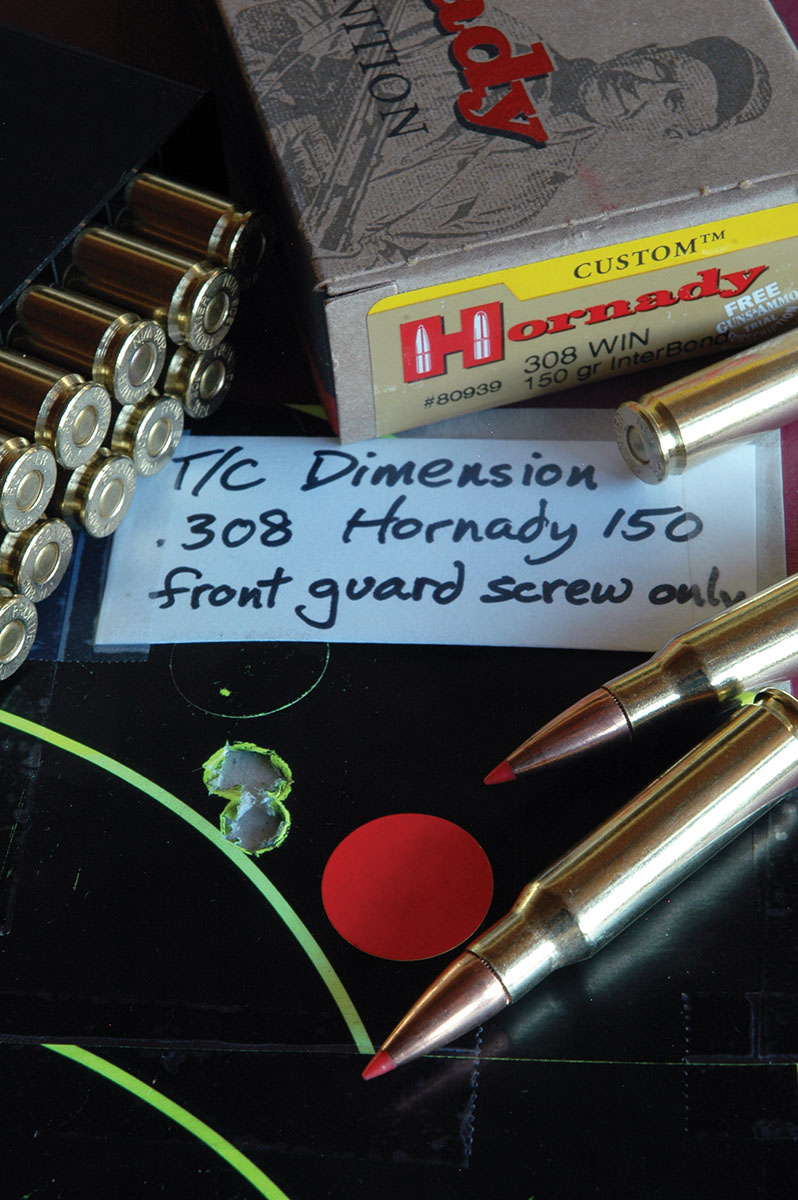

How a barrel is fitted to the receiver affects accuracy. Preston Pritchett, who designed the original Surgeon rifles, told me he threads barrel shanks and mills action faces and lug seats with the receiver held in one fixture. “That way, bolt and bore share the same axis.” Once, to test the design of a Thompson/Center takedown rifle, I assembled it with the front guard screw only. Neither the barrel nor the receiver tail was otherwise supported. Three shots printed a tight cloverleaf at 100 yards. A well-engineered takedown!

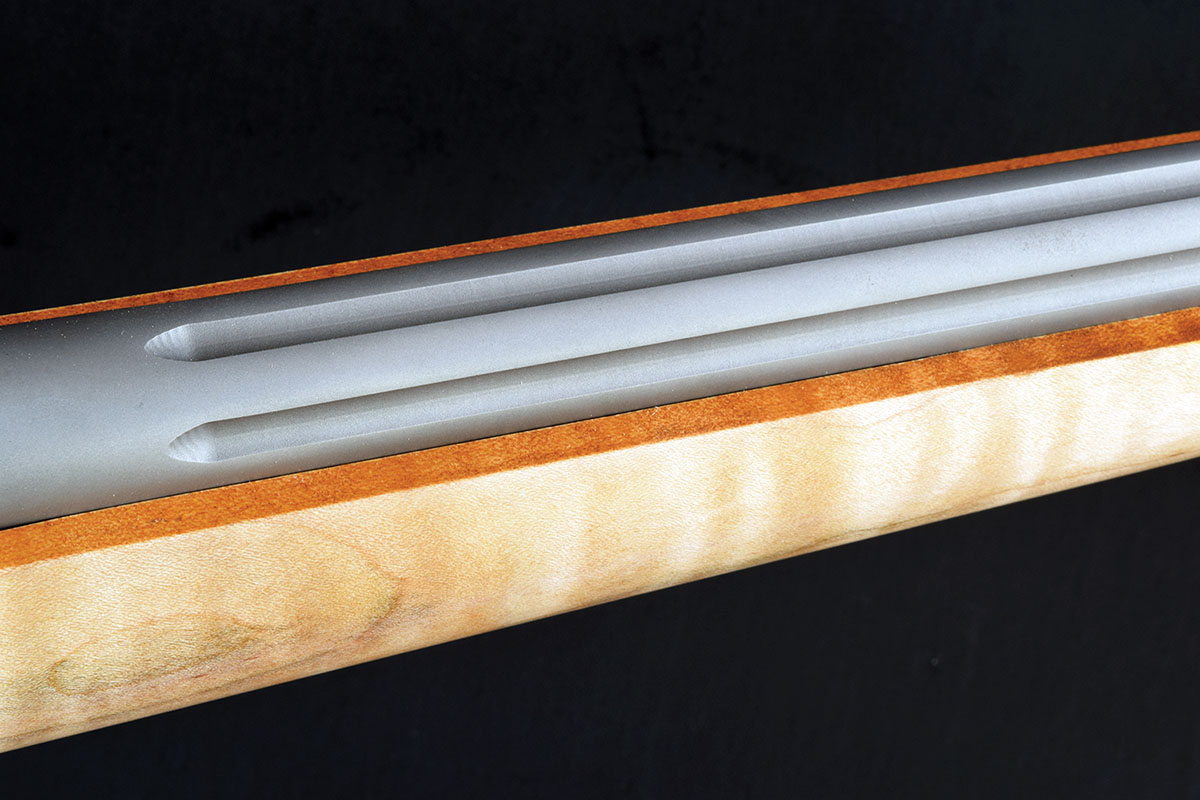

A barrel’s weight is no indication of its accuracy. Some of the most accurate rifles I’ve fired had slim barrels, an Echols Legend 270 Winchester with a barrel diameter .544 at the muzzle, printed dime-size groups; so did a 300 Weatherby at .560 inch up front. A hunting-weight 375 shot into .17 inch, much tighter than I can usually hold. Slender barrels heat more quickly during sustained fire and “walk” more readily as they do. But on a hunt, where three shots amount to protracted assault, a barrel heavier than needed for balance is just a burden. CF wrap and barrel fluting reduce weight with little if any cost in barrel stiffness. They also dissipate heat better than traditional barrels. Of course, fluting requires a thicker barrel wall than might serve on a barrel without flutes – .700 inch at the muzzle instead of .560 inch, for example.

In my youth, “floated” barrels – those not touching anything forward of the receiver – were found mostly on target rifles. Now they predominate. Forend pressure influences barrel vibration, which in turn affects the point of impact and thus, accuracy. We who gagged at the thought of hogging out fore-stocks to free barrels from their bondage applied half-measures. A thin brass or credit card shim near the forend’s nose relieved the barrel of pressure behind it. Some light barrels performed best with up-pressure at midpoint. Glass bedding in the recoil lug recess and forward an inch made some rifles shoot more consistently.

Synthetic stocks and floated barrels have reduced the effect of bedding on rifle accuracy. But the late Don Allen, who founded Dakota Arms, observed that while polymer, fiberglass and CF stocks won’t swell and shrink to the whims of incident moisture, “temperature swings can move them.” On a hot day, you can see a slim polymer forend wilt. Whatever the material or prevailing weather, a sling or bipod can pull a forend from or push it into contact with the barrel. A snug sling limits barrel lift as the bullet leaves, whether or not the barrel channel gap is wide enough to accept a set of car keys. Typically, it moves the point of impact to 7 o’clock. I’ve seen shifts (from bench zero) as great as 4½ minutes of angle!

How can you tell if a barrel is accurate before range-testing it? “You can’t,” said D’Arcy Echols. “One batch of four barrels sent to me included three tomato stakes. The lone exception shot into half an inch.”

Riflemaker Charlie Sisk concurs: “Some barrels aren’t straight. Bores can have bulges and tight spots. You’ll see only the glaring flaws. The rest show up on targets.” John Krieger recommends buying a barrel from a shop with a reputation for good ones “and the willingness to stand behind it.”

Twenty years ago while shopping for a target barrel, I researched the choices of winning competitors. In the 2003 IR 50/50 National matches, 39 of 87 shooters used Lilja barrels. Shilens accounted for 16 of the top 20 placings in the 10.5-pound centerfire class and led in the 13.5-pound class. Hart and cut-rifled Kriegers showed up almost as often. Since then, other barrels, notably Bartleins, have delivered top scores. Douglas barrels on my sporters drill snug groups.

While accurate barrels can fetch high prices, bargains abound. At an IBS (International Benchrest Shooters) match in April 2008, John Lewis sent Lapua 155-grain bullets into a 600-yard group that mic’d at .386 inch. That’s .065 minutes of angle! He bought the 308 barrel, rifled 1:14, secondhand for $50!

But not all shooters or rifles are destined for bench duty and groups the size of a peanut M&M. A Stevens bolt rifle with a stock of cheap polymer once called to me from a used-gun rack. A slim barrel in 300 Winchester Magnum gave it feathery heft – and, likely, haymaker recoil. But its condition and $250 price tag hooked me. Expecting mediocre accuracy at best from this cheap welterweight, I was astonished when my first three bullets cut a .65-inch knot. If there was any recoil, it soon faded from memory.

A final tale: At moose camp in Canada’s bush, Amos had just unpacked his ’61 Chevy. Moving it, he remembered too late his rifle leaning against its tailgate. Pulled from the tire track, the Savage 99’s barrel had a pronounced curve. Amos had few options. “About all I could do was flip the rifle, then run over it again. The barrel looked pretty straight after that.” It was straight enough to bring Amos a moose.