Fouling Shots

5.56 of 1895 Redux and a Few Krag Factoids

column By: Art Merrill | November, 25

His curiosity over the cartridge prompted the reader to order custom reloading dies and rechamber a Ruger No. 1 based on the blueprint drawings of the experimental cartridge and chamber (which appeared in a 1946 American Rifleman magazine). He formed the tapered cases from 9.3x72R brass and was loading 90-grain bullets over Alliant Varmint powder. This reader is still experimenting with his .22 Gov’t 1895 MK II, and he was kind enough to send me two of his fired cases to examine, which I share with you here.

As a related aside, I asked an acquaintance, a 45-year avid cartridge collector (whose fabulous collection should be in a museum to be made available to researchers), if he happened to have one of those extremely rare original “0.22 Inch Caliber Cartridge for Experimental Arm” cartridges. “I did until last year,” he said. “I sold it for a thousand dollars.”

In addition to being America’s coulda-been-first 5.56 rifle, here are a few more Krag factoids of interest; maybe there’s something on this list you didn’t know or that you’ve forgotten:

- Norwegians Ole Krag and Erik Jorgensen designed the Krag-Jorgenson rifle, but Denmark was the first nation to adopt it for military use in 1889, chambered in 8x58mmR. Norway soon thereafter picked up on the Krag in 6.5x55 Swedish, followed by the U.S., which utilized its own U.S. Caliber .30 Government aka .30 U.S. Army cartridge, the name later changed to “.30 Service (Krag) Model 1898”. Upon adoption of the Caliber 30, Model of 1903 cartridge for the M1903 Springfield rifle.

- Though initially tested with black powder, the .30 U.S. Army cartridge was intended from the start to use about 40 grains of smokeless powder, which itself was still under development. Regardless, the cartridge was already made militarily obsolete by new European cartridges such as the 7x57mm and 8x57mm Mauser when the U.S. Army began issuing Krag rifles. The U.S. Army never called the cartridge the “30-40 Krag;” this is a moniker coined later, either by media, marketers or hunter/shooters.

- The U.S. Army’s first Krag was the Model 1892. If anyone ever offers to sell you one of these desirable Krags stamped “MODEL 1892,” pass it up as a fake. No Model 1892s were stamped with that year; rather, Model 1892s bear the stamp “1894” without the word “MODEL.” There were also Models 1894, 1896 and 1898, and they are so stamped.

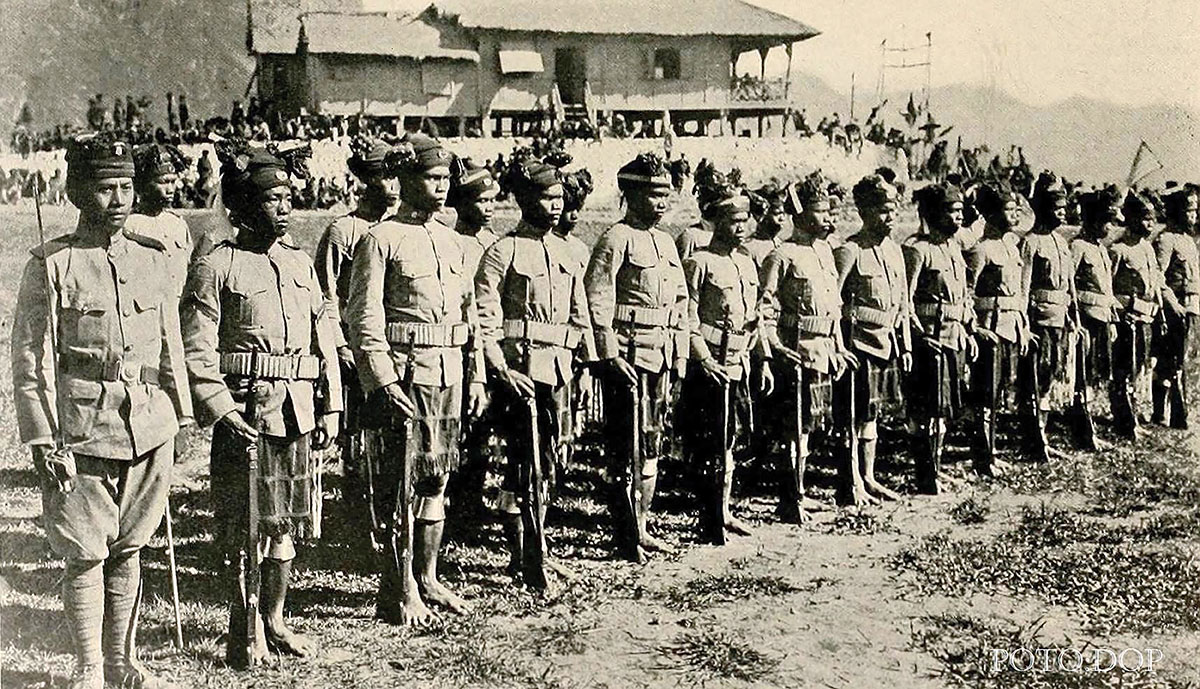

- Though shooters know of Krag carbines and perhaps even of the 3,371 Krag carbines modified into shortened rifles as “school guns” for cadet training, fewer know that the U.S. armory in Manila modified nearly 5,000 Krag carbines to become short rifles for issue to Philippine Constabulary police force. Such short rifles were officially designated, “U.S. Magazine Carbine, Caliber .30, Model 1899,

- Altered for Knife Bayonet and Gun Sling” (Krags originally manufactured as carbines had no provision for bayonet mounting and had saddle rings in lieu of sling swivels). In 2024, the Civilian Marksmanship Program (CMP) offered about 800 short Krag rifles for sale. They quickly sold out. CMP acquires its surplus rifles from the U.S. Army, which doesn’t bother to tell CMP where it obtained each specific rifle. They are typically repatriated loaners from overseas, or drill/parade rifles from American patriotic organizations, so CMP was unable to say whether any of the shorty Krags are actually from the Phillipines.

- Krag rifle bolts were occasionally reported to fail upon firing, cracking behind the single locking lug. Overpressure handloads or re-barreling to a too-high pressure cartridge were sometimes the culprits. In some cases, failure was blamed on excessive headspace, the logic being it allowed the cartridge case to get a running start backward under pressure to slam into the bolt face and overstress the locking lug. Potential bolt failure was well-enough considered that the U.S. Krag bolt guide rib doubled as a backup safety lug, and the root of the bolt handle backed up the guide rib should it, too, fail. On U.S. Krags, the guide rib does not contact the receiver, but it does so on the Danish and Norwegian Krags, so on these foreign Krags, the guide rib acts as a second locking lug instead of merely as a backup. This is why the Danes and Norwegians could chamber their Krags for cartridges more powerful than the 30 U.S. Army.

On Danish and Norwegian Krags, the guide rib serves as a second locking lug by engaging the receiver wall when the bolt is closed. On US military Krags, there is a gap between the guide rib and receiver, so the guide rib acts only as a backup in case of bolt locking lug failure. As shown here, careful honing and lapping of the US Krag locking lug will permit the guide rib to engage the receiver to become a second locking lug. The barrel must then be set back to restore proper headspace.

On Danish and Norwegian Krags, the guide rib serves as a second locking lug by engaging the receiver wall when the bolt is closed. On US military Krags, there is a gap between the guide rib and receiver, so the guide rib acts only as a backup in case of bolt locking lug failure. As shown here, careful honing and lapping of the US Krag locking lug will permit the guide rib to engage the receiver to become a second locking lug. The barrel must then be set back to restore proper headspace.

- The underlying causative factor of Krag bolt failures, however, is similar to that of the infamous “never-shoot low-numbered M1903 Springfield rifles.” Made from carbon steel, Krag (and Springfield) bolts and receivers were heat-treated and quenched in oil, rendering a hard interior and case-hardened exterior that provided excellent tensile strength but made the metal somewhat brittle when it comes to hard shock. This is why the maximum cartridge pressure for the Krag is set at 44,000 Copper Units of Pressure (CUP). Until 1918, armory heat treatment did not utilize pyrometers to measure furnace temperature, instead leaving it to the judgment of the worker, who relied on his experience to determine whether the furnace had reached 1,500 degrees fahrenheit and maintained it for four hours. Misjudgment caused improper heat treatment, which resulted in some subsequent bolt or receiver failures.

- In 1906, Springfield Armory produced a handful of single-shot 22 rimfire Gallery Practice Krags, utilizing barrels made by Harry Pope, the famous maker of Schuetzen competition rifle barrels. This, then, was the U.S. Army’s second foray into making the Krag shoot a .22 caliber bullet, though this time from an already well-established cartridge. In the end, however, the Army’s attempts at mating the Krag with the 5.56, .22 caliber bullet never met with memorable success.