Handloading: A Huge Advantage for Riflemen

Improve Accuracy and Performance

feature By: Brian Pearce | November, 25

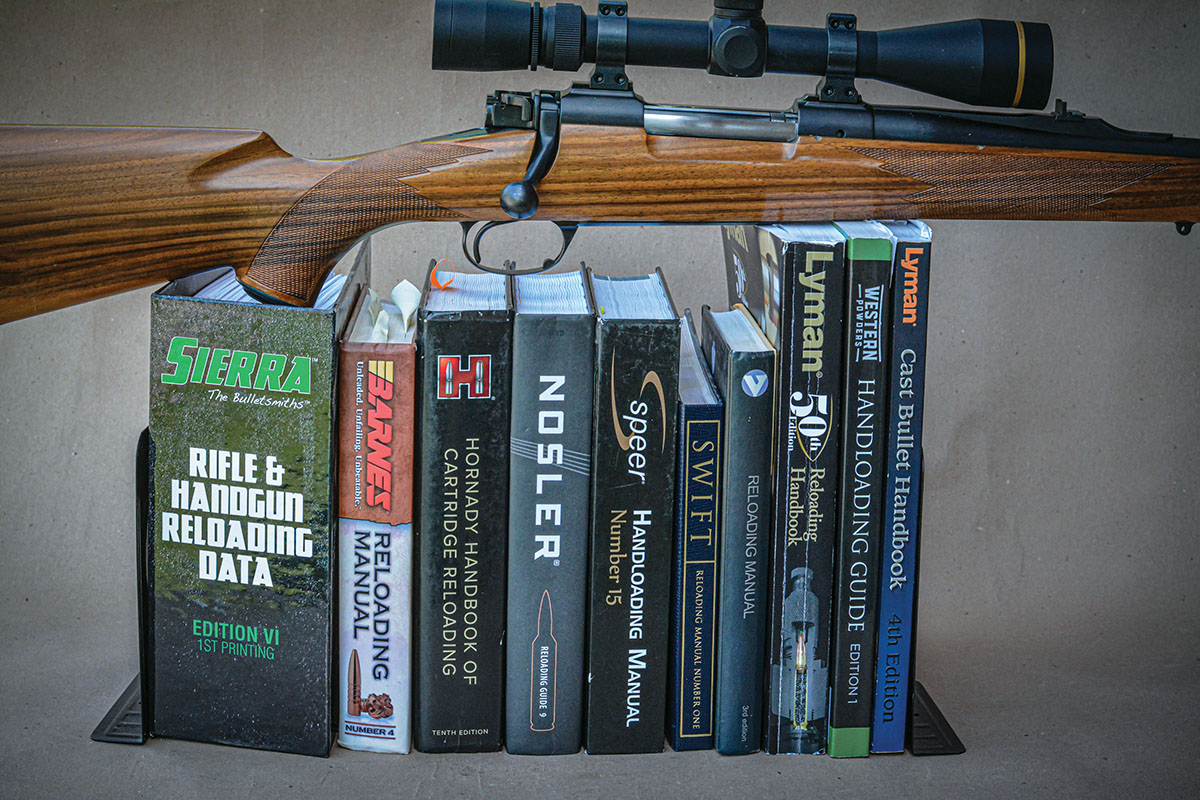

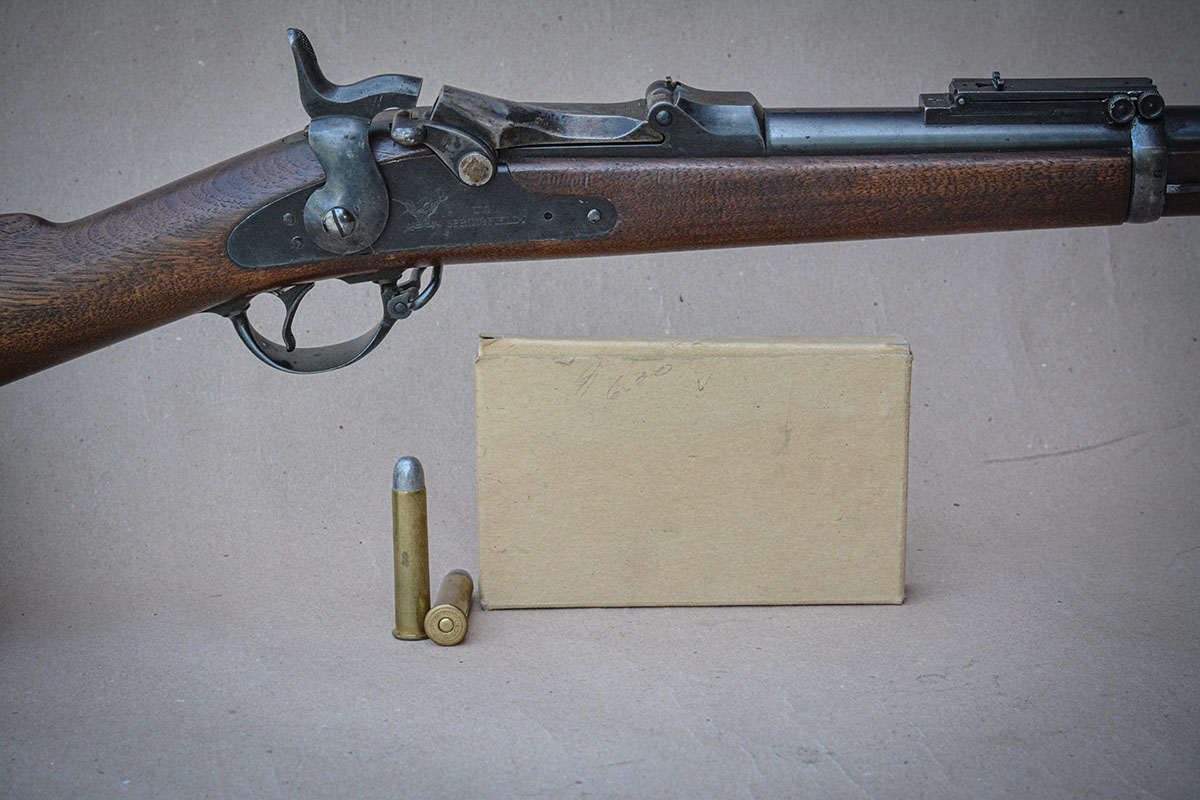

During the muzzleloading rifle era, everyone was a handloader. The ball (also known as the bullet) design and powder charge volume could be selected based on the desired performance. In other words, a load for hunting squirrels would be notably different than when chasing a bear with hounds and ultimately expecting a fight. Even when centerfire metallic black powder cartridges began appearing in mainstream guns during the 1870s, handloading remained very popular in order to save money. Others worked to improve the load with better bullets, better quality black powder for increased accuracy and other advantages. Virtually all buffalo hunters carried handloading tools to cast bullets, size case necks, prime cases and seat bullets. Winchester and other rifle manufacturers even offered hand tools and bullet moulds to aid with handloading.

Incidentally, ammunition factories use the same handloading tools, including presses, dies, scales, etc., that are used by hobbyists to develop each new lot number of ammunition. Every time a new run of bullets is used, a new shipment of powder arrives, or a new batch of cases is produced, handloads are developed that are tested and fine-tuned in a pressure barrel for exact velocity

Factory ammunition has become very good. There are match loads for competitions, premium hunting loads for varmints to large game and lower cost loads for those on a tight budget or for high-volume shooters. Most U.S. ammunition factories are members of the Sporting Arms and Ammunition Manufacturers’ Institute (SAAMI), which is a good thing. In short, SAAMI establishes industry standards on guns and ammunition by detailing specifications and blueprints so that firearms and ammunition are readily

With that thought in mind, let’s say that we have a rifle chambered in 30-06 (or a similar bottleneck cartridge), and accuracy is mediocre with all factory loads have been tried. Through careful handloading development, it is almost always possible to tailor handloads that give much better accuracy. Many things can be done at the loading bench to address accuracy issues, but it usually begins with precision case preparation, followed by using (and weighing) premium powders, match primers, precision bullets, coaxial bullet seating and other high-quality components.

Using expanding copper bullets such as the Barnes Triple Shock X-Bullet, Hornady GMX and second-generation CX and others, they are different animals from cup and core bullets. Many years ago, when the Barnes Vor-Tx ammunition was first introduced, I was forwarded a sampling of preproduction 30-06 loads for evaluation and to try on an upcoming hunt. I had previously developed loads with the rifle using the same 168-grain Triple Shock X-Bullet and knew that this particular bullet needed to be seated deeper (with a shorter overall cartridge length) in order to obtain top accuracy. I referenced my notes and seated the bullets of 20 cartridges .045 inch deeper than the factory had loaded them. I took that box of ammunition along with an unaltered box to my 100-yard range and tested the two loads side by side from the bench. The factory load grouped two, four-shot groups into just over 1.50 inches, but the loads that had the bullets deep seated produced two, four-shot groups that measured more or less into .85 inches - a tiny detail that resulted in groups being reduced to nearly half their size! Again, armed with experience, handloaders can virtually always improve accuracy with some basic experimenting.

Another factor is trying different powder charge weights until the perfect load that maximizes accuracy and corresponds with the harmonics of a given rifle barrel is developed. Space will not allow too much discussion on this subject, but there are many very good canister-grade powders. There are also stand-out powders that yield truly superior accuracy and are engineered specifically for that purpose, as they are super clean-burning and offer extremely low extreme spreads. For shooters and hunters that seek maximum performance in terms of velocity, there are also powders designed specifically for that purpose, while staying within pressure limits. Still other powders, such as Hodgdon CFE 223, might be selected due to their decoppering agent and used in conjunction with high-volume shooting associated with varmint shooters and many other applications. While hunting in Africa and other hot regions (or the frozen North), select powders that are insensitive to temperature changes, such as Hodgdon’s Extreme line. The huge selection of powders available to handloaders to create the perfect load is terrific!

By comparison, ammunition factories are often limited as to what powders they are allowed to use. During powder shortages, they are sometimes forced to use substitute powders. If the ideal powder is not available for a g iven cartridge, then loads are developed with a less-than-ideal powder that leaves something to be desired in terms of accuracy and sometimes are short of standard velocities.

Many years ago, I gently took the top brass of a major ammunition company to task (at their own seminar) for leaving performance on the table, so to speak, with their latest 300 Magnum, which I had already developed loads for prior to attending the seminar. One of the engineers quickly explained that he was the primary designer of the cartridge. He had used a specific powder that was giving higher velocities and better accuracy when compared to the factory loads I had been firing earlier in the day. He continued to explain that when the cartridge specifications were finalized and the factory began loading ammunition, the powder that was supposed to be used was removed from the available list by the company accountant (aka controller, CFO, etc.) due to it costing a few coins more per pound. Clearly, he was frustrated. Handloaders do not face the same problem or limitations; rather, they can choose the most ideal components to maximize accuracy, velocities and overall performance.

Another obvious reason to handload includes ammunition shortages that seem almost commonplace over the past couple of decades and have included popular and less popular cartridges alike. If you happen to shoot a less popular cartridge such as the 17 Remington, 218 Bee, 25-20 WCF, 223, 243 and 25 WSSMs, 250 Savage, 225 Winchester, 220 Swift and a host of others, when shortages occur, these are always the first cartridges to be dropped by ammunition producers in favor of higher-demand rounds. Many European-based cartridges also disappear. There are many vintage USA black-powder era lever-action and single-shot rounds that likewise will require handloading if you want to shoot them. Many of these rounds are best when used with low-pressure smokeless powder loads, or black powder, and used in conjunction with cast bullets to minimize barrel wear of those wonderful vintage rifles. Such loads and cartridges are generally not available from ammunition companies and are largely a handloading proposition.

Briefly, let’s discuss modern cartridges that can become significantly more versatile through handloading. For example, many high-performance bottleneck cartridges are only offered with full-power loads. This is somewhat like getting into a car and only having one speed option, which is 80 miles per hour. Consider the hugely popular 300 Magnums. Handloaders can easily reduce their power level to 30-30, 308 Winchester, 30-06, etc., as needed. They can be loaded with very light loads containing cast bullets at 1,000 feet per second (fps) for harvesting small table fare with minimal meat damage, dealing with barnyard pests, or perhaps using subsonic loads containing high ballistic coefficient (BC) bullets to be used in conjunction with a suppressor. Handloaders can easily adjust the speed and performance of modern cartridges for lower recoil or any specialized application.

Ammunition factories have become very competitive by offering premium hunting loads for the most popular sporting cartridges. However, many vintage cartridges such as the 250 Savage, 300 Savage, 30-40 Krag, etc., have been overlooked and only have very limited loads available that consist of traditional cup and core bullets. While their performance is okay, it literally has not changed for a century in spite of much better bullets in terms of accuracy and terminal performance being available. Handloaders can employ modern bullets such as the Barns TTSX-Bullet, Nosler Ballistic Tip, Swift Scirocco, Hornady SST or many other options for truly premium performance on big game and enjoy their heirloom or classic rifle in the field. This will require handloading, but accuracy and field performance can also be substantially improved.

As indicated, saving money is a bonus with handloading, but most importantly, the overall performance of ammunition can be improved, and it is a great way to learn technical details about your guns. It is incredibly fun to shoot tight groups or drop a distant buck with ammunition that you created. If you do not subscribe to Handloader magazine, you are missing out on the only magazine of its type that boasts of technical articles that are not available elsewhere.