The Ruger Custom Shop Ruger 10/22 Competition with a Trijicon Accupower 5-50x 56mm scope attached to its 30 MOA rail with Weaver 34mm 6-screw rings. When shooting the rifle for accuracy, an M-LOK adaptor from GG&G Tactical was used to attach a Harris bipod.

The stock has a length-of-pull adjustment range of 13 inches to 14.5 inches and Layne found 14 inches to be a good fit. Extremely narrow, the butt of the stock leaves a bit to be desired for shooting with it resting on a sandbag.

Since its debut in 2018, Ruger’s Custom Shop has produced quite a few special variations of standard-production handguns and rifles, and the 10/22 Competition (Model No. 31227) with a carbon fiber tensioned stainless-steel barrel featured in this column is the latest. My digital postal scale put its weight at 4 pounds, 6.5 ounces. I am not sure when or where the tensioning concept pertaining to firearm barrels originated, but I first encountered it years ago on

While the narrow check rest of the stock is height adjustable, Layne found it to be too high in its lowest position and compensated by using higher rings when mounting a Trijicon scope.

revolvers built by Dan Wesson. I still have the Pistol Pac option in .357 Magnum with barrels in four lengths. Quite thin, the non-tapered barrel measures only .470-inch in diameter and is threaded at both ends. When installing a barrel, one end is turned into the frame of the pistol until it makes contact with a feeler gauge used to set the cylinder gap. A steel sleeve containing the front sight is then slid over the barrel until it rests against the front of the frame. The muzzle end of the sleeve is recessed for a spanner nut, which engages the threads in that end of the barrel. Using a wrench (included with the gun) to tighten the nut secures the barrel in position while exerting a stretching or tensioning force on it. Due to excellent accuracy, Dan Wesson revolvers became quite popular among those who shot revolvers in metallic silhouette competition.

The chassis stock of the 10/22 Competition has a MAGPUL MOE-K grip and is compatible with other AR-15-style grips.

Back to the latest Ruger 10/22 Competition rifle, rather than having the usual carbon-wrapped barrel, its thin barrel is enclosed by an extremely rigid carbon fiber tube or sleeve. While most of the barrel is turned to a small diameter, a shoulder with a diameter matching the outside diameter of the carbon fiber sleeve remains at the receiver for that

Ruger’s BX trigger on the test rifle had about the same amount of take-up as a standard-production 10/22, but with an average pull weight of 2.8 pounds on a Lyman digital scale. It is a bit more than 3 pounds lighter. The transverse safety button at the front of the trigger guard is easy to reach and operate.

end of the sleeve to bear upon. The diameter of the barrel in that area is also the same diameter as the front opening of the 10/22 receiver. A ½-28 threaded shank at the muzzle of the barrel is long enough to accept a .270-inch thick, flat nut while leaving .380-inch of the shank for the attachment of an included brake. A spanner wrench used by a factory technician to tighten the nut applies a pulling or tensioning force on the barrel, and does so to uniform and dampen harmonic vibration.

With the barrel shank of the standard-production 10/22 inserted into the receiver, it is secured by a steel v-block held in place by two screws. Tightening those screws pulls the barrel hard against the face of the receiver with all the force of the v-block exerted only against the bottom edge of the barrel. This has long been a satisfactory design detail for the standard 10/22 because it has a very light barrel. The first 10/22 Competition rifles built by the Custom Shop had heavy all-steel barrels that placed more stress on the receiver than it was designed to handle. Making the optic rail an integral part of the receiver increased its rigidity, and equally important, it created room for the threaded hole of an additional fastener called the upper barrel retainer screw. The screw is positioned parallel with the barrel, and when tightened, the underside of its head bears on a small shoulder machined into the top of the barrel. Retention force is both increased and equalized by applying the same amount of force at the top of the barrel as the v-block applies at the bottom of the barrel.

To release the hinge of the stock for folding to the left-hand side, grasp the stock with one hand and the frame with the other hand, with both hands positioned close to the hinge of the stock, then push up on the frame while pulling down on the stock,. Doing so shortens the overall length to 26.5 inches with the muzzle brake attached and 25 inches with it removed.

When the stainless-steel barrel is being machined to a small diameter for weight reduction, a shoulder at the receiver with the same diameter as the carbon fiber tensioning sleeve is left for it to bear on. That section of the barrel is also of the same diameter as the front opening in the receiver.

There was one other modification. On the standard 10/22, a single bolt screwed into an extension at the front of the receiver holds the stock and barreled action together. The installation of a heavy free-floating barrel exerts a heavy downward load on the front of the receiver, and that tends to lever the rear of the receiver upward. That issue was addressed in the early 10/22 Competition rifles by attaching an aluminum bedding block to the rear of the receiver. A second action bolt reaches through the stock just behind the trigger guard and screws into the bottom of the bedding block. With that bolt

This target’s close-up view shows the muzzle of the 1/2-28 threaded barrel with the barrel tensioning nut attached. When the barrel is assembled at the factory, a spanner wrench is used to turn the nut clockwise, applying force against the front of the carbon fiber tube - which fits loosely around the thin stainless steel - with its opposite end resting against a shoulder machined into the barrel at the receiver. This stretching or tensioning force on the barrel uniforms and dampens harmonic vibration. Not seen here, the threaded shank extends .380 inch beyond the tensioning nut for attachment of a muzzle brake or suppressor.

added, both ends of the receiver are pulled firmly into the stock with equal force. Due to the lighter weight of the carbon-tensioned barrel of the latest 10/22 Competition (making the optic rail integral with the receiver) added sufficient stiffness, thereby eliminating the need for the additional front and rear fasteners required on Custom Shop rifles with heavy all-steel barrels.

As a 22 Long Rifle cartridge is pushed into the match-dimensioned chamber of a bolt-action rifle built for competitive shooting, its bullet engages the rifling for precise bullet-to-bore

alignment. Due to the possibility of slam-firing in an autoloading rifle, that type of chamber cannot be used in the Ruger 10/22. Chamber dimensions of the 10/22 Competition are quite close to those of the Bentz chamber, which has long been used by gunsmiths who specialize in building super-accurate 10/22 rifles. Its diameter is a closer fit with the .22 Long Rifle cartridge than the sporting chamber seen in most rifles, but not close enough to compromise feeding and extraction. Shorter than a sporting chamber, it positions the bullet of a chambered round closer to the rifling, but it does not engage the rifling as in a match chamber.

The receiver is CNC-machined from heat-treated and stress-relieved Type 6061-T6511 aluminum bar stock and it has a black hard-coat anodized finish. The integral Picatinny rail is 5.25 inches long with a 30 MOA forward slant. When combined with the right scope, the accurate little rifle is just the ticket for long-distance competitive shooting,

The attached muzzle brake with its back end resting against the barrel tensioning nut.

which nowadays is 300 yards and sometimes beyond. The precision-machined steel bolt is heat-treated and then finished with durable black nitride. Fully retracting the bolt and then pushing on a familiar lever at the front of the trigger guard locks the bolt in that position. Pulling the oversized bolt handle a bit to the rear and then releasing it allows the bolt to move forward into battery. An oversized ambidextrous magazine release wrapped around the front of the trigger guard is an easy reach for the trigger finger. Push the lever and the 10-round rotary magazine gravity-drops into the open hand. The BX-25 magazine from Ruger works equally well for quickly sending lots of lead downrange during a mass attack of flickertails..

The 10/22 Competition has Ruger’s BX trigger, and while the one on the test rifle had about the same amount of take-up as the trigger of the standard-production 10/22 - an average pull weight of 2.8 pounds on a Lyman Digital Scale - it put it a bit over 3 pounds lighter. My trigger finger detected a tiny bit of creep but no trace of overtravel. Reset is fairly long. A transverse safety button at the front of the trigger guard is easy to reach, while a strong ball detent discourages it from being accidentally moved out of a chosen position.

The bolt with its oversized handle is precision-machined for a close fit with the receiver. It is then heat-treated and given a durable black nitride finish. Fully retracting the bolt and then pushing on a familiar lever at the front of the trigger guard locks it in that position. A tug on the handle releases the latch, allowing the bolt to move forward into battery.

The barreled action rests in a chassis-style aluminum stock made by Grey Birch.

A 10-inch modular forend has an abundance of M-LOK and Arca-Swiss compatible slots for accessory attachment. The stock has a MAGPUL MOE-K grip and is compatible with other AR-15-style grips. Stock length-of-pull adjustment ranges from 13 inches to 14.25 inches, with 14 inches proving to be good to go for me. The narrow cheek rest is height adjustable, but with it resting as low as it would go, it was too high for me. Switching to higher rings for the Trijicon scope took care of that. Instructions on folding the stock are not in the owner’s manual, so doing so required a learning curve. Pushing, pulling, twisting and pressing the hinge in every direction did not work. I eventually learned that grasping the stock with one hand and the frame with another, with both hands positioned close to the hinge, and pushing up on the frame while pulling down on the stock, unlocks the hinge for folding the stock to the left-hand side. Doing so shortens the overall length to 26.5 inches with the muzzle brake attached and 25 inches with it removed. The rifle is also available from the Custom Shop with a more conventional Magpul MOE X-22 stock with a speckled finish.

When shooting the 10/22 Competition for accuracy, I utilized Weaver 34mm 6-screw rings to attach a Trijicon Accupower 5-50 X56mm scope. The scope was chosen, not because I needed all that magnification, but because I would be punching paper at 50 yards, and its parallax adjustment ranges from 10 yards to infinity. An M-LOK adaptor from GG&G Tactical was used to attach a Harris bipod up front. Quite narrow, the tapered butt end of the stock measures barely over an inch at the top and .720 inch at the bottom, not exactly ideal for shooting over a rest. While rapid-firing five rounds, I ended up using the thumb and fingers of my left hand to squeeze the rear of the stock between the ears of a rabbit ear leather bag filled with sand.

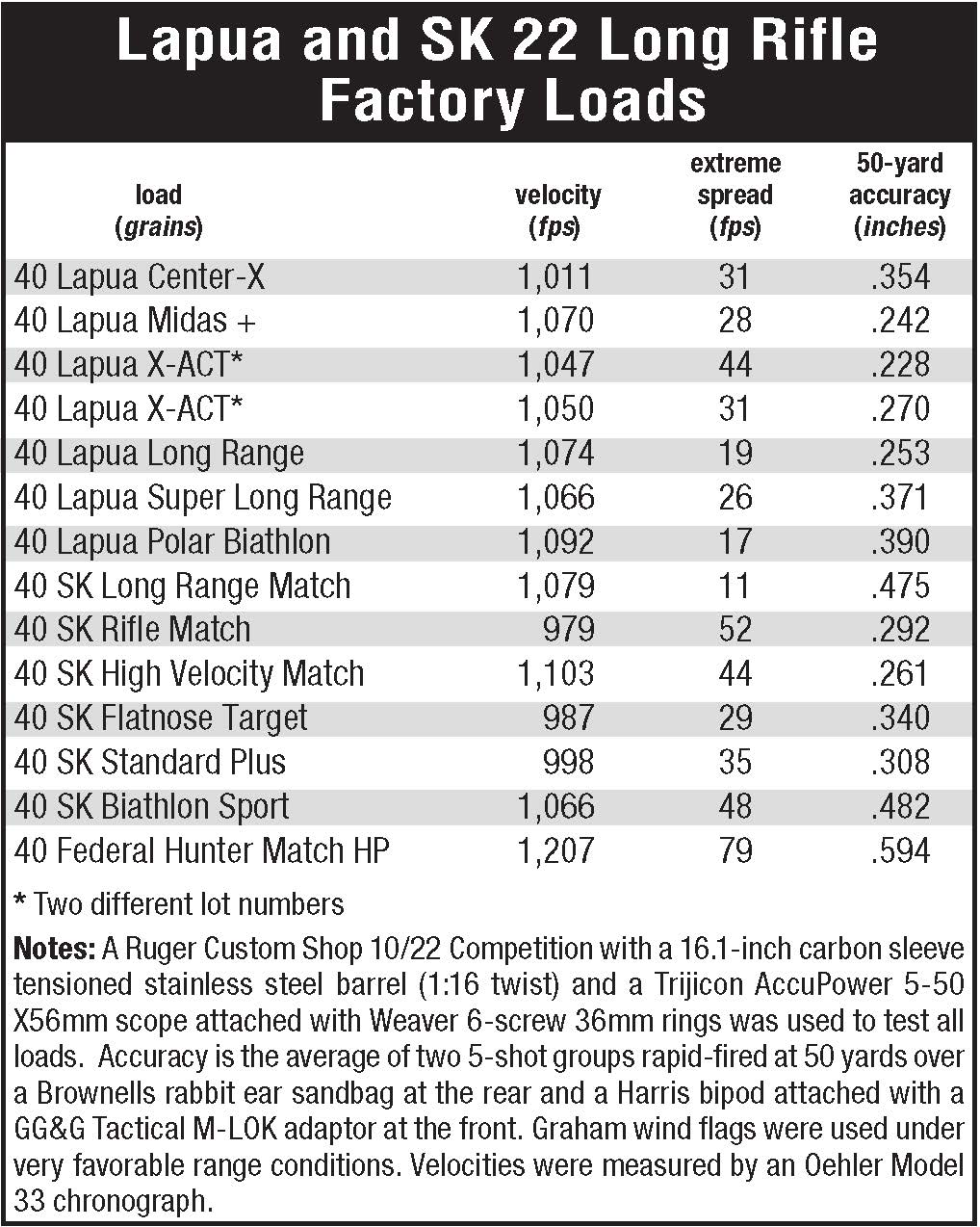

When evaluating the accuracy of a new match-grade barrel chambered for the 22 Long Rifle, the barrel should first be seasoned a bit by coating its bore with lubricant from the bullets of the ammunition to be used. Some barrels require more rounds than others, but I usually fire 100 rounds through the barrel prior to shooting groups. Due to differences in lubes on the bullets of various brands of ammunition, changing ammunition often requires seasoning the barrel with that ammunition. When shooting the Custom Shop 10/22 Competition for accuracy, I chose Lapua and SK ammunition for two reasons. First of all, both are produced at the same factory in Germany, and while they are loaded on different production lines, their bullets are of the same lead alloy mix, and they have the exact same lubricant. Equally important, nothing out there is more accurate. After seasoning the 10/22 barrel with 100 rounds of SK ammunition, I began shooting groups. A wind flag 10 yards down range and another adjacent to the target were positioned so both could be observed in the scope with its crosshairs on the target. After sitting back and observing the flags long enough to spot a condition that came around most often, I was ready to start pulling the trigger. Each time that condition came around, I sent five bullets down range in less than three seconds.

As explained by Layne in the text, the heavy all-steel barrel of the earlier 10/22 Competition rifle built in the Ruger Custom Shop required stiffening the aluminum receiver by giving it an integral optic rail. Additional front and rear receiver fasteners were also required.

With a lighter scope, such as the Bushnell Rimfire 3-9x40 attached, the 10/22 Competition would be a dandy small game rifle. For this reason, I finished my accuracy testing by shooting groups with Federal Premium Hunter Match ammunition loaded with a 40-grain hollowpoint bullet. I was not surprised when it delivered headshot accuracy a bit beyond 50 yards. Cartridge feeding with the 14 test loads was totally reliable and after the firing of just over 325 rounds, no lead shavings had appeared at the leading edge of the magazine or chamber.

Lapua and SK ammunition is loaded on different production lines at a factory in Germany. Important when accuracy-testing an extremely accurate rifle, the bullets of both have the same lubricant.

The instruction manual included with the rifle warns against the use of CCI Stinger ammunition. While not mentioned, the same applies to CCI Quik-Shok, Aguila Super Maximum, and any other ammunition with a case longer than is standard for .22 Long Rifle ammunition. Chambering one of those cartridges in the chamber could force the mouth of the case hard into the rifling leade with the increased grip of the case on the bullet, resulting in a dramatic rise in chamber pressure. It could also result in a dangerous out-of-battery slamfire.

The 10/22 Competition, along with a certificate certifying Ruger Custom Shop build, comes in a hard case at a total price of $1,129.