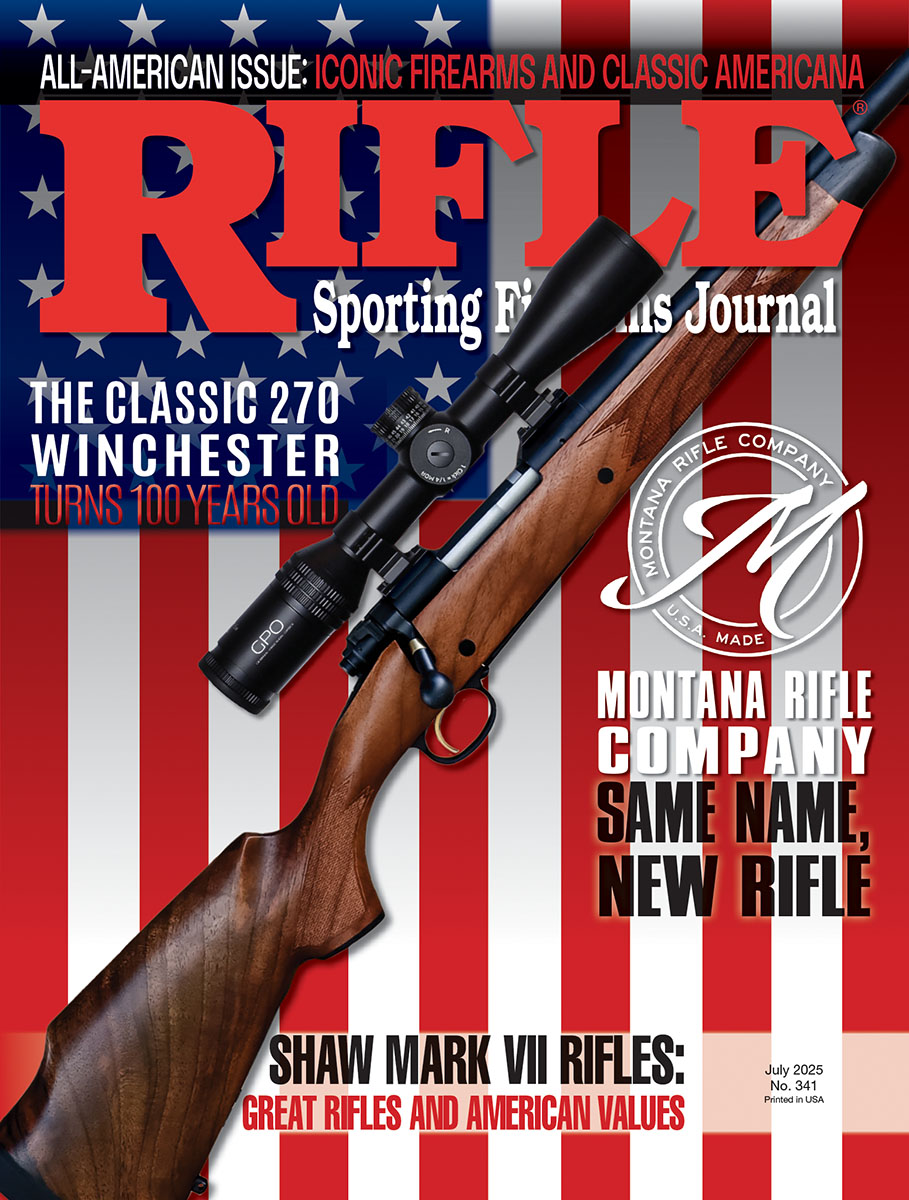

Layne’s Mark VII rifles have laminated wood stocks and 26-inch stainless steel barrels with 1:7 twist. The rifles utilize Talley rails and Weaver 30mm 6-screw rings to hold Bushnell 6-24x 50mm scopes. Both rifles have Harris bipods and Nosler compensators – SR-30 ALTi on the 22-250 (top) and SR-30 Ti on the 22 Creedmoor (bottom).

The short and long versions of the Mark VII action are built by Savage to Shaw’s specifications. Blueprinting performed by Shaw include lapping the locking lugs and truing the faces of the bolt and receive ring.

The story of the Pennsylvania-based company once known as E.R. Shaw and recently changed to Shaw began in 1913 with the founding of Small Arms Manufacturing, a major supplier of .30-caliber barrels for the United States Army during World War I. The

The bolt of the Mark VII action has a Shaw-designed, teardrop-shaped handle rather than the Savage handle. Pressing the tab down on an extension of the sear shown here, just forward of the bolt and holding back the trigger, frees the bolt for removal from the receiver.

company later supplied barrels of .30 and .50 calibers for various U.S. military firearms used in World War II, the Korean War and the Vietnam War. Sometime during the 1950s, the Shaw division of the company was formed to serve the commercial market by selling hundreds of rifle barrels each month to gunsmiths who used them when building rifles on 1903 Springfield, 1917 Enfield and various Mauser actions that were both abundant and inexpensive on a thriving military surplus market. A mail-order service supplying barrels to hobbyists across the country was eventually added.

Barrels made by Shaw are button-rifled and available in chromoly or stainless steel in over 150 chambering options ranging from the 17 Remington Fireball to the 458 Lott. They include many of the oldies as well as the latest to be introduced. With the exceptions of P.O. Ackley’s improved versions of the 223 Remington, 22-250, 243 Winchester, 250 Savage, 257 Roberts, 25-06, 6mm Remington, 338-06 and 35 Whelen, all chambers are reamed to SAAMI (Sporting Arms and Ammunitions Manufacturers’ Institute) dimensions. A barrel can be short-chambered by about .050 inch for a gunsmith who has the correct finish reamer, or it can be long-chambered for a gunsmith who does not have the correct reamer but who is capable of facing off the barrel when fitting it to an action.

The safety slide of the Model 110 action is a 3-position design. Pushing the slide all the way to the rear blocks trigger travel and bolt rotation. Pushing it to the middle position allows the bolt to be rotated for loading or unloading the chamber with the trigger still blocked from movement. Pushing it all the way forward (shown here) readies the rifle.

Barrel contours ranging from light sporter to heavy magnum in various lengths ranging from 16.5 inches to 26 inches are offered. You can order a barrel with straight fluting, helical fluting, or plain with no fluting. Blackening the surfaces of the flutes on a stainless-steel barrel while leaving the rest of the surface in white is another option. There are also quite a few rifling twist options, with examples being 1:10, 1:9, 1:8 and 1:7 for .243/6mm

As triggers on mass-produced rifles go, the Savage AccuTrigger is quite good. It becomes even better after being subjected to a process described by Shaw at triple-honing. The triggers on both of Layne’s Mark VII rifles were easily adjusted to break smoothly and crisply at 30 ounces with no trace of creep or overtravel.

barrels and 1:14, 1:12, 1:9, 1:8, 1:7 and 1:6.5 for those of .224 caliber. Muzzle threading for brake or suppressor attachment is available, and a thread protector is included. Shaw sells a lot of match-grade barrels for the Ruger 10/22, with the latest being a thin stainless-steel barrel wearing a titanium sleeve. It is rated at 56 percent lighter than an all-steel barrel of “bull” contour.

Sending an action to Shaw for the installation of a barrel has long been quite popular, but before taking the plunge, be sure and check the company’s website to see a list of actions that are not accepted. Finish options are blued for chromoly and polished or bead-blasted matte for stainless steel. If blueprinting the action is desired, various operations such as lapping the locking lugs and truing the faces of the bolt and receiver ring will be done. Trigger replacement is also on the will-do list. Drilling and tapping the receiver for scope mounting has long been available for 1903 Springfield, 1917 Enfield and various Mauser actions.

Complete rifles are also offered, and as you might guess, the S-10 and S-15 are Shaw’s custom versions of the AR-10 and AR-15 rifles. The available design options are too numerous to be included here, so I will simply say that as this is written, the S-15 is available with a barrel ranging from 16 to 24 inches in 5.56mm, 223 Wylde, 6mm ARC, 6.5 Grendel, 300 BLK, 300 HAM’R and 350 Legend. The S-10 is offered in 308 Winchester, 6.5 Creedmoor and 6mm Creedmoor.

The Excursion rifle on a stainless steel, turn-bolt action of Shaw’s design comes with a sub-MOA accuracy guarantee. Depending on customer-chosen options, it weighs from 6.25 to 8.25 pounds. Short and long actions in left- and right-hand configurations are available, all with Triggertech triggers and Hawkins M5 bottom metal. The list of available chamberings is too lengthy to include here. The Excursion uses an AICS pattern magazine with a Peak 44 Blacktooth carbon fiber stock weighing a mere 20 ounces. The barreled action only is also available.

Threading the muzzle for suppressor or muzzle brake attachment it an option. Layne chose 5/8-24 for his two rifles.

Exterior stainless-steel barrel treatment options are helical fluting (shown here), straight fluting or no fluting. Blackening the surfaces of the flutes while leaving the rest of the barrel in the white is another option.

Moving on to less money but still in the minute-of-angle class is the Mark VII on a Model 110 action built to Shaw’s specifications by Savage Arms. This is indicated by a serial number with an S prefix. Each action is blueprinted by Shaw technicians, and during the process, the feed ramp and rails of the receiver are polished to improve cartridge feeding and bolt travel. The bolt also has a teardrop-shaped handle of Shaw’s design rather than the Savage handle. A precision-machined recoil lug measuring .280-inch thick is sandwiched between the face of the receiver and a shoulder machined into the barrel. The familiar Savage barrel retention nut is not there. A process described as “triple-honing” transforms the good Savage AccuTrigger into what can only be described as an excellent AccuTrigger. Those on my two rifles were easily adjusted to pull weights of 30 ounces, with no detectable trace of creep or overtravel.

When designing the Model 110 action for Savage back in the 1950, Nicholas Brewer exposed an extension of the sear at the right-hand side of the receiver bridge and gave it a grooved tab. Holding down that tab with the thumb while holding back the trigger frees the bolt for removal from the receiver. The tab also serves to indicate the firing pin position. Some Model 110 actions built by Savage today still have that original design, while removing the bolt from other 110 actions also being built is accomplished by pressing a release at the front of the trigger guard while holding back the trigger. I very much prefer the original design and am happy to see the decision makers at Shaw specify it on 110 actions built for them by Savage. As most who own Savage 110 rifles know, the safety slide on the tang of the action has three positions. All the way to the rear blocks both trigger travel and bolt rotation, while the middle position allows the bolt to be rotated for loading or unloading the chamber with trigger movement still blocked. Push the safety all the way forward and a pull on the trigger will fire the rifle.

The Mark VII is presently available only with a blind magazine although a hinged floor plate or detachable magazine is being considered. Note the pads of synthetic bedding material positioned behind and in front of the recoil lug of the receiver. From the front pad on, the barrel free floats.

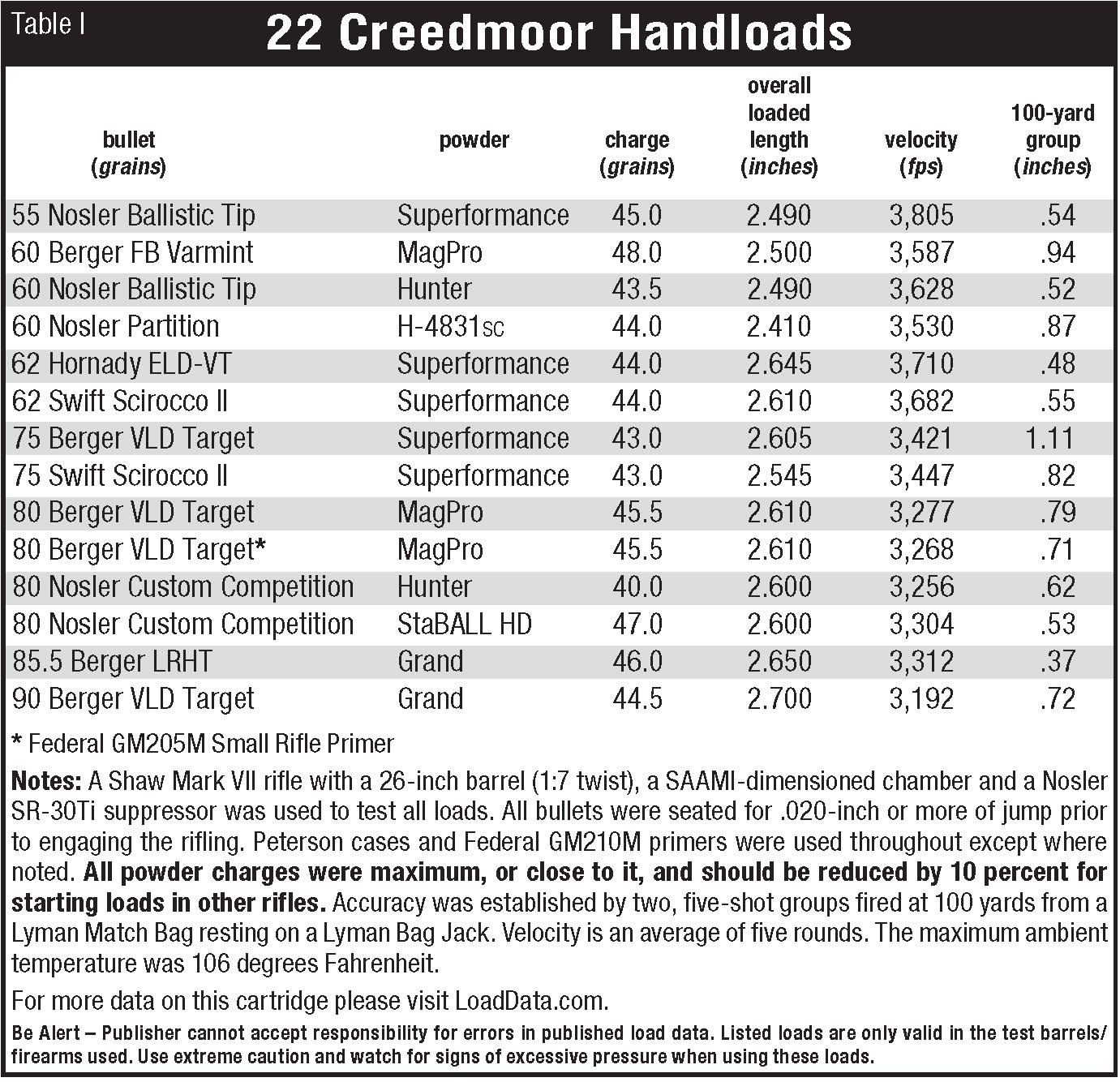

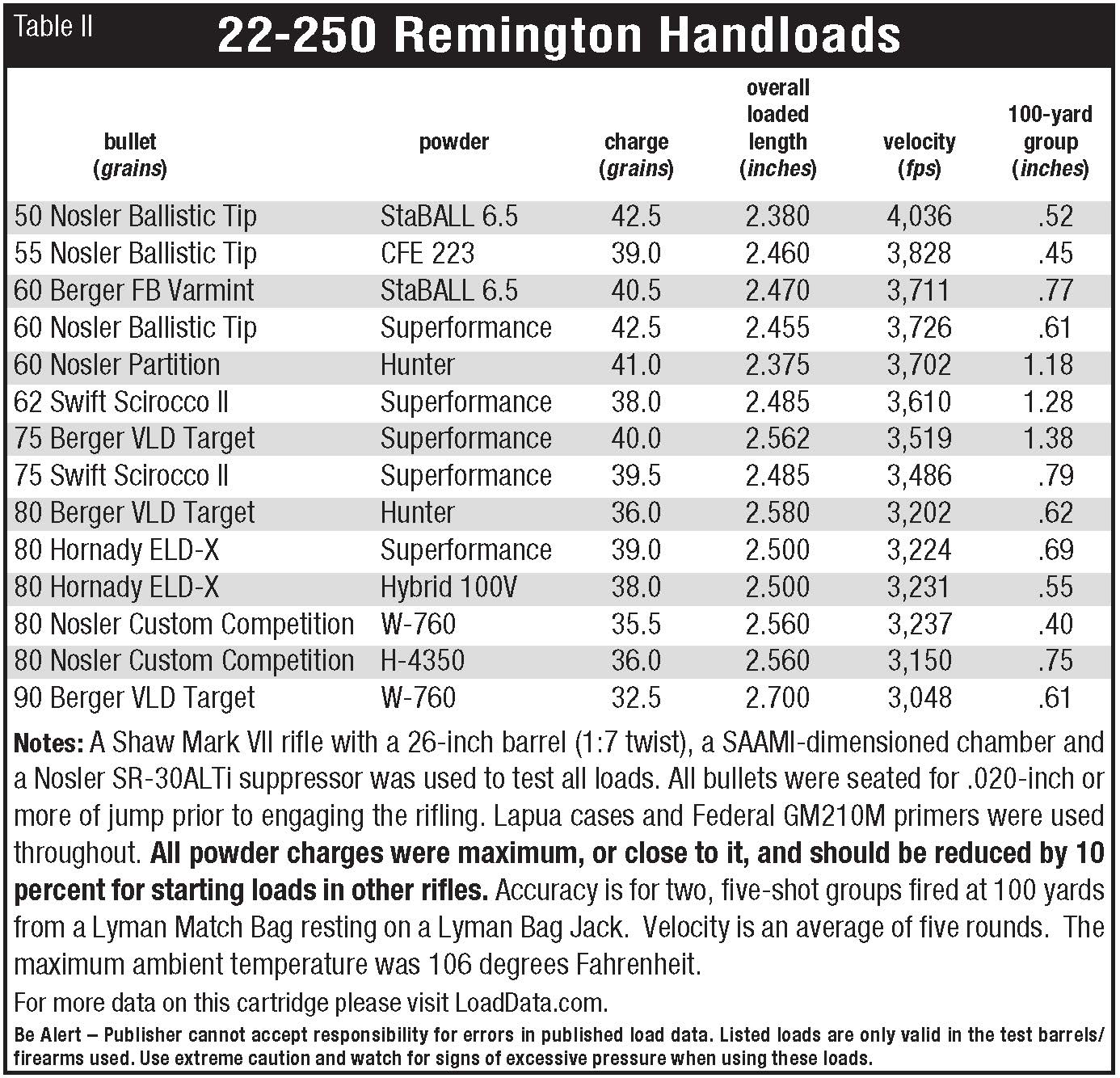

I have been shooting two Mark VII rifles, one in 22-250 and the other in 22 Creedmoor, and I am impressed. The chamber dimensions of both were reamed to SAAMI dimensions. Both have 26-inch, stainless-steel barrels, and their 1:7 twists enable me to shoot bullets ranging in length from the 50-grain Nosler Ballistic Tip to the Berger 90-grain VLD Target. Their muzzles are threaded 5/8-24 for attachment of suppressors that make them even more pleasant to shoot. Thread protectors were included.

The barreled actions of my rifles were hand-bedded in stocks of laminated wood. Shaw buys the blanks from one source and has them shaped, inletted and finished by another. I have long had a soft spot for the weight, stability and looks of laminated stocks on varmint rifles and chose a brown coloration (or Nutmeg as Shaw calls it) for the 22-250 and Pepper (gray) for the 22 Creedmoor. The stocks have a Pachmayr recoil pad and posts for quick-detach sling swivels, with the one up front positioned correctly for use of a Harris folding bipod. The barreled action is hand-bedded in the stock and rests on pads of synthetic material. The front pad extends beyond the front of the recoil lug to support 1.75 inches of the barrel, and from there, the barrel free floats. Both rifles have blind magazines.

Peterson 22 Creedmoor cases are available with Small Rifle and Large Rifle primer pockets, while Lapua 22-250 cases have Large Rifle primer pockets. Excellent ammunition for both rifles was loaded with Redding die sets. The Berger 90-grain VLD Target, Swift 75-grain Scirocco II and Nosler 55-grain Ballistic Tip were among the bullets Layne used in his accuracy-velocity testing of the two E.R. Shaw rifles. Superformance ranks high among a number of excellent powders suitable for loading the 22-250 and 22 Creedmoor.

As expected, the weights of my two rifles ended up quite close to the same with my postal scale indicating 9 pounds, 9.9 ounces for the 22-250 and 9 pounds, 10 ounces for the 22 Creedmoor. Talley rails and Weaver 30mm 6-screw rings were used to attach Bushnell 6-24x 50mm scopes – a Match Pro with the Deploy Mil reticle on the 22 Creedmoor and an Engage with MOA reticle on the 22-250. That increased the weight of the two rifles to an ounce shy of 10.75 pounds, heavy enough to hold steady on a windy day while being light enough to carry on varmint shoots that require a lot of walking. Where legal and at reasonable distances, either rifle equipped with a lighter scope and pushing the Nosler 60-grain Partition, Swift 62-grain Scirocco II or Swift 75-grain Scirocco II at maximum speed would be extremely effective on pronghorn antelope and whitetail deer.

To avoid possible confusion, I will close by mentioning that for many years, the “Gun Builder” section of Shaw’s website enabled a customer to pick and choose among various options and basically end up with what some would describe as a custom rifle. Several months after my two rifles were built to my specifications, I was informed that the program had been discontinued and the Mark VII rifle will now be available only with the options that have proven to be the most popular through the years. The goal is to reduce wait time by having rifles in stock. The price has not been finalized as I write this, but I was told it should be around $1,300. Everything should be in place at Shaw by the time this article is published.