TANDEMKROSS’s ChamberMade Ironing Swage is made for the DIYer to easily iron away the peened metal.

We’ve all heard that we should never dry fire a rimfire rifle because it will cause damage, but that is not the whole story. The fact is that it is perfectly okay to dry fire some rimfire rifles, such as the Ruger 10/22, and the dry-fire practice is routine among 22 Long Rifle competition shooters. Manufacturers do not always tell us which rifles fall into that “OK” category, and considering that for nearly all semiautomatic 22s, there is no other way to release mainspring tension on an empty rifle other than by dry firing.

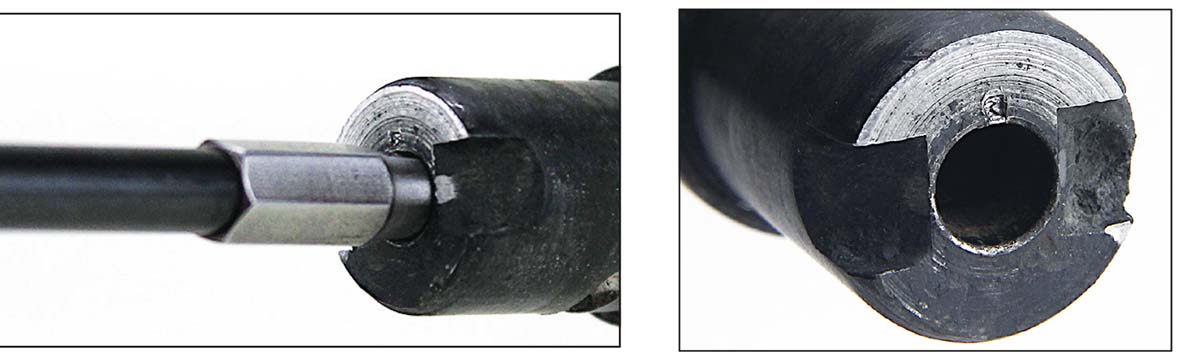

On many 22s, dry firing can cause the firing pin to peen the breech face and result in chambering and extraction problems.

In rifles in the “Not OK” category, damage occurs when the firing pin strikes the breech face with no cartridge case present in the chamber. Firing pins are hardened steel, so they can survive being hammered at the back end and stopped suddenly at the front end. Dry firing can break a firing pin, but more often repeated dry firing will peen a dent in the breech face, which appears as a bit of metal extending into the chamber. That dent can delay a cartridge from entering the chamber, resulting in faulty feeding, or it may prevent chambering the cartridge at all. If the round does chamber, the dent can impede or prevent extraction of the case.

It does not take a machinist or gunsmith to fix the problem; the do-it-yourselfer (DIYer) can iron the dent with a simple, inexpensive ChamberMade Ironing Swage from the 22 tool and upgrade specialist TANDEMKROSS. The versatile tool offers four very effective methods for ironing a 22 rimfire chamber, and one or more of them will work with any rifle or pistol.

A hardened steel cylinder tapered to fit 22 Short, 22 Long and 22 Long Rifle chambers, the ChamberMade is a swage with a flat on one side. Male threads on one end accept a cleaning rod’s female threads; the opposite end is female to accept male threads. The latter end’s outer portion is also shaped to take a 1⁄4-inch wrench or hex driver, and the end is recessed to accept a punch.

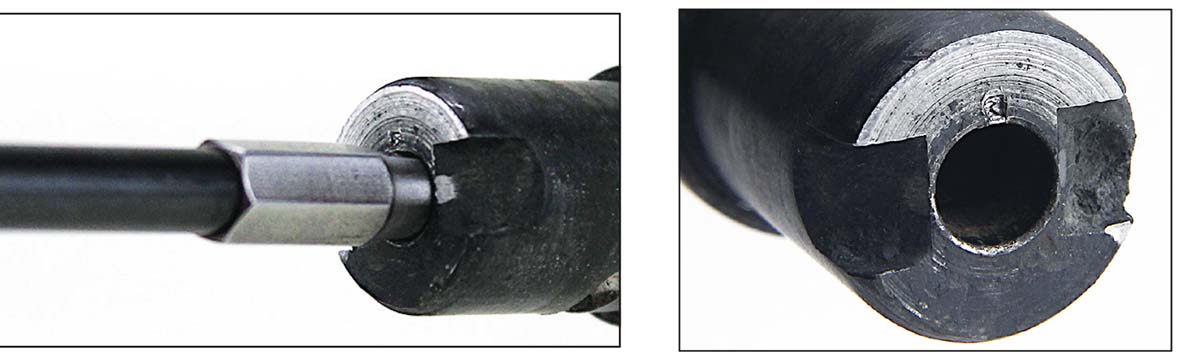

Insert the ChamberMade (above) and apply pressure while turning – the peened metal is ironed (right) and you’re back to shooting again.

After oiling both the clean chamber and the ChamberMade to prevent galling, method one is to insert the ChamberMade into the chamber with its flat facing the peened dent. Place a 1⁄4-inch hex driver or breaker bar with a socket over the ChamberMade and push hard while turning. As the tool rotates under pressure, it irons the dent, usually in just a few turns; it may take a dozen or so turns of the tool to fully iron out a stubborn dent. Because most 22 barrels are pinned or threaded to the receiver, an extension to the hex handle may be necessary to reach the swage while it is in the chamber.

If the peening is particularly stubborn or a hex driver cannot be used, method two is to thread a short piece of rod into the back of the ChamberMade so that the flat faces away from the dent and tap the top of the rod with a small mallet. Do not overdo it; otherwise, you may have trouble removing the swage from the chamber.

The ChamberMade can be used four different ways by employing simple tools.

Method three is an approach similar to method two using a 1⁄8-inch drift punch instead of a threaded rod. Insert the punch into the back of the ChamberMade’s female recess and proceed as above. Again, lubricate with oil and do not overdo the tapping. If the swage does get stuck with method one or two, with a bit of finesse, you can insert a cleaning rod from the muzzle, thread it fully onto the swage’s male threads, and tap it out of the chamber with the palm of your hand or light mallet taps.

Those methods work well with break actions and bolt actions after removing the bolt, and with many pistols after removing the slide or barrel. Method four is the go-to technique for semiautomatic rifles that have no access through the back of the receiver. Insert a cleaning rod from the muzzle until the end protrudes far enough to allow threading the male end of the ChamberMade onto the rod’s female end. Attach locking pliers (a vise grip) to the cleaning rod close to the muzzle, align the swage’s flat to face the dent, then pull backward (toward the muzzle) forcefully on the cleaning rod while turning the rod with the locking pliers.

When finished, clean the chamber with alcohol or another degreaser to remove the oil before shooting. To prevent a repeat of the peening, insert a fired brass cartridge case in the chamber when dry firing, testing an action or de-cocking a semiautomatic. Resist the temptation to attempt “garage gunsmith” ironing of a 22 chamber with a tapered punch; the punch’s taper and length are unlikely to be correct and can damage the chamber, throat or rifling. The ChamberMade is designed not to contact the throat or leade of 22 Short, 22 Long or 22 Long Rifle SAAMI standard, match or Bentz chambers.

Tandemkross sells the ChamberMade swage for $30, available at TANDEMKROSS.com.