Heat-Treating Barrels

Keep Your Shots From Walking

feature By: John Barsness | March, 20

John decided to buy a New Ultra Light Arms rifle as a present to himself so he could keep hiking around after deer and elk, despite the hills and mountains becoming increasingly steeper each year. He bought the NULA after discovering how well the three Eileen and I own balanced, because like many hunters, his experience with light big-game rifles involved shorter, thinner barrels, resulting in very muzzle-light balance.

Instead, NULAs weigh less because the actions and synthetic stocks are very light, so they can be fitted with standard barrels. Ours have 24-inch No. 2 contour Douglas barrels with muzzles measuring .600 inch in diameter, yet weigh well under 7 pounds with a typical 12-ounce hunting scope. (Melvin Forbes, owner of NULA, uses Douglas as his standard brand, partly because Douglas is located in Charles Town, West Virginia, an easy drive from the NULA shop in Morgantown, but also because they shoot well.)

John decided on the 7x57 Mauser, because like many older hunters he is not fond of recoil, and as an avid handloader, he knew the old round would work fine on elk with the right bullets. However, after the first range session, he mentioned being disappointed in the accuracy, since three-shot groups rarely measured less than about 1.5 inches, no matter the load.

Any rifle with a properly heat-treated barrel and good stock bedding should do the same thing – and waiting five minutes (or two, or whatever) between shots often results in larger groups. Spreading out the firing practically guarantees the shooter will hold the rifle somewhat differently for each shot, which affects light rifles more than “standard” rifles.

It also generally means the wind will change, and even an erratic 5-mph breeze can result in .75 inch of extra spread at 100 yards. This is why so many successful target shooters quickly fire as many rounds as possible during a certain “wind condition” – obviously not waiting for the barrel to cool between shots.

John looked skeptical, but I explained “hot stability” is why my NULA .30-06 is my favorite rifle for testing scopes. The light rifle not only recoils enough to reveal mechanical problems, but it remains very accurate as the barrel heats up, speeding up the test. (Personally, I cannot imagine waiting several minutes between shots when testing scopes or handloads. Life is too short.) It may seem criminal to shoot such an accurate hunting rifle fast enough to get the barrel hot, which tends to shorten barrel life, but as Melvin Forbes frequently points out, Douglas makes new barrels every week.

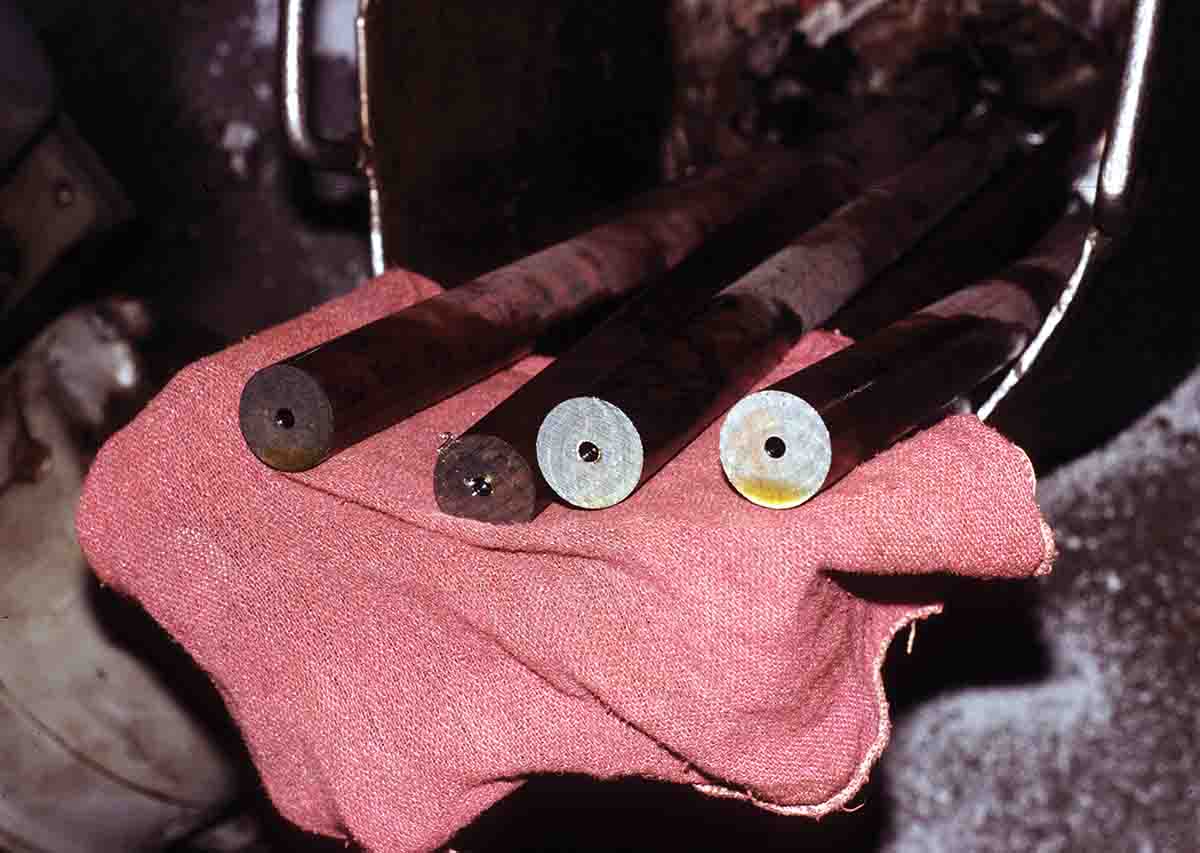

So what is heat treating, and how does it affect rifle barrels? Basically, any metal can be heat-treated in order to achieve certain goals, but in barrel steel heat treating removes stresses introduced both during the manufacturing of the cylindrical steel bars used to make barrels, and during the rifling process. I have visited several barrel factories and talked extensively with other barrelmakers. So far, every company buys long cylindrical bars formed by cold-rolling, which are then stress-relieved at the factory, sometimes twice.

This is accomplished by heating the bars to 1,000/1,100 degrees Fahrenheit (exactly how hot depending on the type of steel), then cooled slowly. This eliminates internal stresses, allowing the barrelmaker to drill straight holes. The hole is next reamed to the correct bore diameter then rifled, which may or may not reintroduce stresses into the steel, depending on the method.

Cut rifling generally does not stress the barrel, one reason many shooters consider cut-rifled barrels most accurate. Among the most highly regarded are made by Krieger Barrels Inc. I have owned several Krieger barrels over the years, and all shot very well.

The company’s website describes the technique: “We rifle all of our barrels using the single- point cut-rifling process. Although our machines are state of the art, the process itself is the oldest and slowest method of rifling a barrel. It’s also the most accurate. The cutter removes approximately .0001 inch, or 1 ten-thousandth of an inch, at each pass, thus taking several hundred passes to rifle a barrel. This method produces almost perfect concentricity between bore and groove, a very uniform twist rate, and induces no stress into the steel that later has to be relieved.”

I have owned about the same number of cut-rifled barrels, both new and rebored, made by Dan Pederson at Classic Barrel & Gunworks, who also does not heat-treat barrels after rifling. My latest CB&G is a slim .257 Roberts barrel Dan fitted to an FN Mauser commercial action, and it does not “walk” any more than his other barrels – which is not at all.

Hammer forging rifling is generally claimed to introduce the most stress into barrel steel, since a bunch of mechanical “hammers” quickly pound a drilled steel bar around a rifled mandrel. The bar starts out very thick and short but gets pounded into a typical longer, thinner barrel shape.

This would obviously seem to stress steel, but as with just about any subject these days, somebody will offer a contrary opinion on the Internet. While researching this article, I came across a short YouTube video by a company that hammer forges barrels, where a spokesman stated: “Because the barrel is made so perfectly by compression, and because it’s cooled the whole time it’s compressing, you never get any of those stresses of cut rifling.”

Other European companies have been hammer-forging their barrels for quite a while. In 2015, I was one of a number of gun writers who toured the Sako and Tikka factory in Riihimaki, Finland. Both brands have a reputation for superb accuracy, partly because the same hammer-forged barrels are used for each. I specifically asked if they are heat-treated at the factory, and the answer was a very definite yes.

Somewhere in between are button-rifled barrels. The bar steel is drilled and reamed like cut-rifled barrels, but the rifling is formed by a very hard metal “button,” perhaps an inch long, with a mirror image of the grooves on its surface. The button is pulled or pushed through the lubricated bore while being turned at the desired twist rate.

Dan Lilja is known for making very accurate button-rifled barrels. Aside from visiting his Montana shop, I have probably had as many rifles fitted with Lilja barrels as any brand of custom barrel. His website includes a description of the post-rifling heat-treatment: “When a barrel is button-rifled, no material is removed to create the grooves. Rather, the steel is cold formed and moved outward. This process introduces some stress into the steel, and this stress must be removed. The best method of doing so is by heating the barrel to a temperature of about 1,100 degrees and holding the steel at that temperature for a pre-determined time. To prevent decarburization of the steel it is best to perform this step in a vacuum furnace where the atmosphere is pumped out. Following this heat treating the barrels are completely stress free.”

So with all this heat-treating going on, why do some barrels walk? Well, there are other possible reasons than the barrel itself. Probably the most common is barrel bedding. In Rifle No. 301 (November 2018) I reviewed the first commercial .308 Winchester ever produced, the “pre-64” Model 70 Featherweight. Both the rifle and cartridge appeared in 1952 and probably played a role in the belief that lightweight barrels walk as they heat up, even though all pre-’64 barrels of any contour were cut-rifled.

The problem with the original Featherweights was not the slim barrel. Instead it was the barrel bedding, which was really screwy. Winchester claimed the barrels were free-floating, but instead they were only slightly loose in the forend channel, so during firing they vibrated against the wood. According to more than one review of the new rifle and cartridge, this resulted in subpar accuracy (which today would be considered not just poor but completely unacceptable), with five-shot groups often measuring 2 to 3 inches, and sometimes more.

My Featherweight .308’s stock bedding was unaltered, and that is exactly how it initially shot. I then temporarily free-floated the barrel with a pair of plastic shims placed behind the recoil lug. The rifle then started shooting very well, with no sign of barrel-walking. Three-shot groups with nine handloads and five factory loads averaged .85 inch. The best handload grouped five rounds into around an inch, shot as fast as I can aim accurately and fire.

Another potential bedding culprit is the “tip hump” in many factory rifles, a pressure point at the front of the forend channel designed to dampen barrel vibrations. These can work very well in a stable, precisely made stock, but unfortunately in other stocks the amount of pressure varies and can be especially wimpy in many of today’s injection-molded models. The barrel can also be off-center in the hump, or the hump may be uneven enough to provide at least two pressure-points. As a result, quite a few pressure-bedded hunting rifles walk their shots as the barrel gets warm, and the barrel gets blamed.

Part of the problem may have been Winchester promoting the .223 WSSM as the ultimate prairie dog round. No other kind of hunting burns barrels quicker than intensive prairie dog shooting in summer weather, and I have seen visible signs of throat erosion through my Gradient Lens bore-scope after only 250 rounds of .223 Remington ammunition was fired quickly. Accuracy of that particular .223 Remington, however, remained very good for thousands of rounds.

The .223 WSSM’s price was so low I suspected the barrel might be shot out, so asked permission to take a look with my bore scope. There was only a little erosion so I bought the rifle and a few boxes of factory ammunition.

It would not group three shots into much smaller than 3 inches with either the factory ammunition or handloads, even after I tried several bedding tricks. Finally, I sent the rifle to gunsmith Charlie Sisk for a new Lilja barrel, and when Charlie started to unscrew the old barrel, its threads were so undersized the shank rattled around inside the action. The Lilja barrel is a “medium sporter” with a muzzle diameter of .660 inch, which shoots great and does not walk as it warms up.

This rifle generally fired the first two shots close together, but after that they started to scatter in any direction. Allowing the rifle to cool even 10 minutes after each group did not help. Instead, it had to cool at least half an hour. The bedding was fine, with the epoxy-bedded wood evenly contacting the barrel throughout the forend – but I also tried the temporary free-floating trick, and the rifle shot the same way.

The mystery was finally solved one day when talking to a fellow gun writer who had tested more than one rifle from that particular company. He said their barrels all walked because (as he eventually discovered) they were heat-treated after drilling and reaming, before they were button rifled. The barrel-maker adamantly claimed this was the proper method.

The “walkingest” rifle I have ever owned, however, was a synthetic- stocked .22-250 Remington with a very stout button-rifled barrel made by an American factory known for affordable but accurate rifles. This was 20 years ago, back when many prairie dog shooters (including me) used a .223 Remington for shooting out to about 250/300 yards, and a .22-250 for longer shots.

After mounting a reliable scope, I sighted-in with some factory ammunition left over from another project, and the rifle consistently put five shots considerably under an inch. I then took it on a couple of trips hosted by ammunition factories and after more than five shots the point-of-impact raised and moved left a couple of inches. How quickly this happened depended on the ambient temperature, but if I kept whacking away it occurred even on relatively cool days. Did the rifle company assume heavy barrels did not require heat-treating? I do not know, but the rifle went down the road.

These days I shoot a Remington 700 in .204 Ruger at what used to be .22-250 prairie dog ranges, a factory rifle that started off as its VTR with a triangular barrel contour. It did not walk its shots even when the barrel got so hot I consciously avoided touching it. The hot shooting eventually burned out the barrel, but not for a couple of seasons. I replaced it with a new Remington factory barrel, a stainless sporter purchased for around $100 from an Internet site. It does not walk when hot either.

If your rifle walks its shot, something is wrong and the problem is probably not the barrel.