Light Gunsmithing

Big-Bore Plinker Project - Part 1

column By: Gil Sengel | May, 17

Riflefolk are always on the lookout for another interesting rifle. A good friend and sometimes hunting partner was a perfect example. One fine day this chap learned of a double rifle for sale by its original owner. After looking at the gun, he bubbled and stewed for a week, like a pot of campfire chili that had been left a little too close to the fire.

Carl told me the rifle was powerful, lightweight and perfectly balanced. It was ideal for elk in the timber. When it was pointed out that he already owned over half a dozen rifles that had killed many elk in heavy cover, the response was that they were okay, but bolt guns were slow to get off a second shot if the animal was running. How about his four custom leverguns? Well, they were fine too for normal running game, but working the lever made it hard to follow animals that were running uphill! Needless to say, he wound up buying the double rifle.

Carl is gone now. I miss hearing his stories and looking at his latest rifle acquisition. Those memories came flooding back when a Model 1891 Argentine Mauser turned up with missing parts and a rusted bore. This particular action cocks on closing the bolt and feeds from an in-line magazine that protrudes below the stock about an inch and a half. The magazine, however, was missing.

One look at the old, neglected rifle told me what had to be done.

You see, Carl had one of these that he called a “gem”; a rifle that would never be sold or traded. It had been rebarreled for another cartridge, its military stock was cut back and open sights were installed.

Carl once said that, to his knowledge, the rifle had never been fired at a living thing. Instead, it was used just for the joy of shooting and was loaned to fathers and grandfathers for introducing young shooters to a “big” rifle they could easily handle. I know it was great fun for me and hard to put down until the ammunition ran out. Therefore, my old friend, this project is dedicated to you.

As indicated, the cartridge fired by this project rifle has a big bore but it’s small of stature in that it is the .45 ACP, a pistol round. One of two reasons for using it is because Carl’s rifle had been built in the 1960s when .45 ACP surplus ammunition was widely available and inexpensive. Fifty rounds of surplus could be had for less than the cost of one round of some of today’s specialized self-defense ammunition. If a shooter was also a bullet caster, handloads could be made up for less than one penny each.

The second reason for the autopistol round is that it has the same base diameter as the 7.65x53mm military cartridge for which the M91 Mauser was chambered. Also, the M91 uses what we today call

a “push-feed” mechanism and a “Sako-type” extractor, meaning that cartridges don’t have to be fed from a magazine to prevent breaking the extractor. In the 1960s, surplus arms dealers sold rifles with bores in fine shooting condition for $20.00 to $25.00. Many of them also had unadvertised quantities of the same guns with unshootable bores and poor stocks for sale at half that.

I am quite certain that is where the M1891 Argentine rifle used for this project originated. The firing pin, spring and magazine box assembly were missing, while the bore was so rusted no rifling could be seen. Someone had also cut the military stock and attempted to refinish it. Nevertheless, it was fine for my intended use – especially at the asking price of $25.00.

Some readers may question the use of the M1891 action given that it cocks on the closing stroke of the bolt. This drives a few people right up the wall, to the point where they won’t shoot such a rifle. Yet these guns are easier for youngsters to operate, because they seldom have the wrist strength to prevent the rifle from rotating when the bolt is lifted on a cock-on-opening action. The same is true for some adults who fail to make a fast follow-up shot on game, because the rifle has to be taken off the shoulder to gain enough leverage to lift the bolt handle.

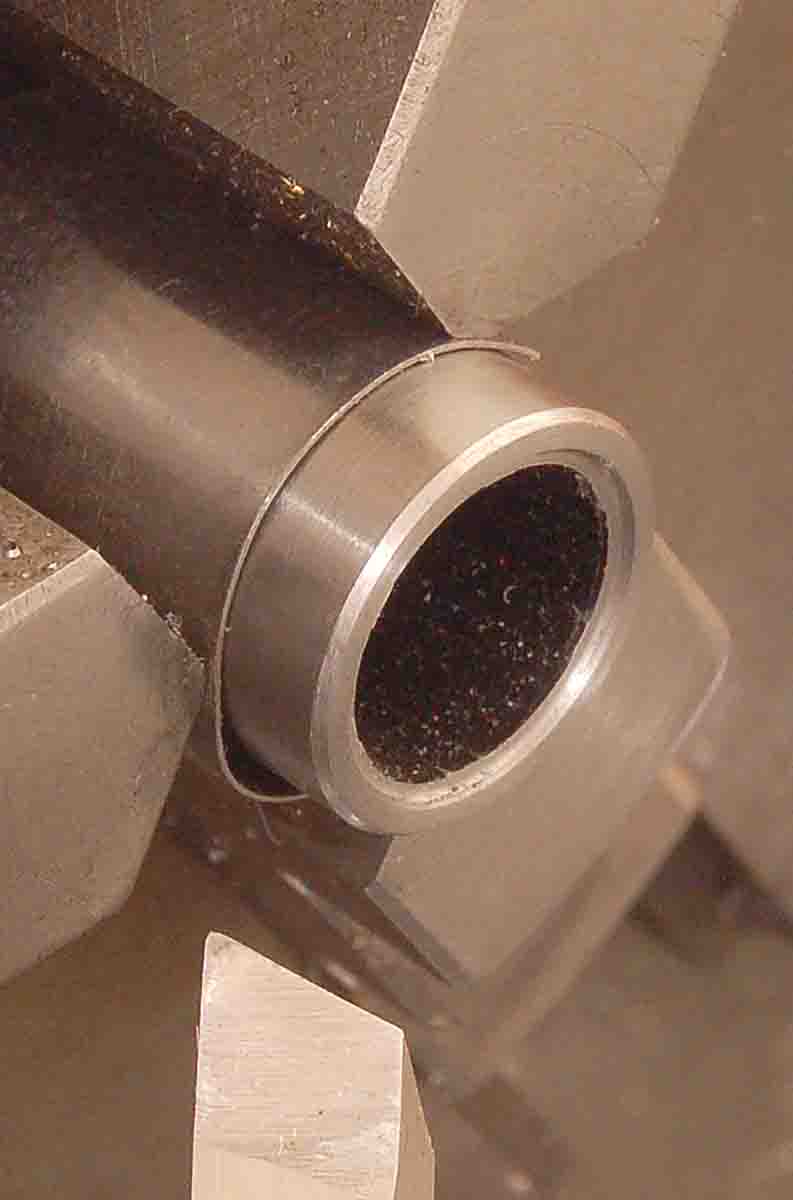

Barrel installation is simple on the M91, because there are no bolt nose or extractor cuts to make. The barrel on my rifle is a Douglas No. 3 contour, .451-inch (.45 ACP) groove diameter, one-in-16-inch twist and 24 inches long. Barrel length was selected to see if a subsonic load could be developed that would not require wearing bulky ear protection. The chamber was cut with a reamer I already had, but most gunsmiths and hobbyists probably won’t want to buy a reamer for just one rifle. No problem: There are outfits that rent reamers, such as 4D Reamer Rentals.

The barrel contour mentioned fits the M91 military barrel channel closely, but the new barrel is a bit large just forward of the receiver. When relieving this area, I took out extra wood under the barrel and in the recoil lug area so Brownells’ ACRAGLAS epoxy bedding could be added for a perfect fit.

Now is also the time to cut back the forend if it’s still military length. The proper procedure is to measure the barrel length forward of the receiver ring, then divide this number into five equal parts. The sum of two of these parts is the correct forend length from the front of the receiver ring.

Magazine work is next, though it is possible to get by doing nothing at all and simply poke rounds into the chamber, totally ignoring the magazine and follower. Carl’s M91 .45 ACP of long ago was shot this way. He and a couple of gunsmith friends had tried to adapt pistol magazines to the rifle, but several attempts failed. In my case, the missing magazine box and follower allowed rounds to sometimes fall through the hole onto the ground.

To remedy this problem, the rotary magazine retainer located immediately behind the front guard screw was removed. This left a hole just large enough to allow a 10x32-tpi machine screw to pass through. A piece of 1⁄8-inch thick steel plate was then shaped to fit over the magazine hole in the bottom metal. It is retained by a 10x32-tpi screw in the front and the military magazine box latch at the rear. The smooth, flush surface thus produced makes the rifle far more convenient to carry than if the military magazine was hanging down below the stock.

All that is then needed is to fit a piece of wood into the magazine recess in the stock. It sits against the new floorplate on the bottom and protrudes up through the receiver into the bolt raceway. Here it is cut concave to allow the bolt to just miss touching it. A loaded round can now be dropped on the concave surface and the bolt closed. Feeding is flawless for roundnose bullets and most bullets with tapered noses, such as the Hornady XTP. After using this rifle for several months, it seemed that the wood insert in the magazine made loading so much easier than pushing cartridges into the chamber; I recommend it over using an unaltered gun.

The next column will look at several necessary and unnecessary details plus a nifty idea for sights. Of course, the rifle will also be shot, because that’s the most important part!