Marlin's New 1894CS .357 Magnum

Plus a Customized Model 1895SBL .45-70

feature By: Brian Pearce | May, 18

In 2010 Marlin Firearms, part of the Remington Outdoor Company, moved manufacturing from New Haven, Connecticut, to Ilion, New York. This was a most difficult move and resulted in practically all valuable employees staying behind. Over the next couple years, lever-action rifles were assembled from existing parts inventory by new employees, resulting in substandard overall quality and function. New CNC tooling was purchased and blueprints were reestablished and programmed to correspond with the new equipment. The first CNC-produced .30-30 WCF rifles began to roll out in 2013, but there were still quality and design features that had to be addressed. Additional cartridges have been added to production, including .45-70, .44 Magnum, .45 Colt and .35 Remington.

This particular Marlin rifle has been in high demand, as I have witnessed guns produced from 1979 (the first year of .357 Magnum production) through 2010 regularly selling for $1,000 to $1,200, on those rare occasions that they become available, while Cowboy versions bring notably more. The Model 1894CS .357 will be initially offered in carbine configuration with an 18.5-inch barrel. At this point, the stainless steel version is scheduled for early 2019 production, while the Cowboy Carbine with 20-inch octagonal barrel is scheduled for production by April 1, 2018. And later in 2018, a threaded barrel carbine will be optional.

Before discussing the new levergun in detail, consider the use of the .357 Magnum in a rifle (or carbine). As I have mentioned in previous articles, this little cartridge is far more potent than its paper ballistics indicate. I first began using .357 Magnum rifles in the 1970s, mostly in converted Model 1892 Winchesters and Rossi Model 92SRCs, which when kept within reasonable range limits, have accounted for a number of deer and other big game. When children came along, my young sons put Marlin .357 Magnum leverguns to work on raccoons, beavers, coyotes, pests and deer. With properly placed bullets, we have never had to shoot a deer twice. They also offer comparatively mild recoil, and the lightweight carbines are especially quick handling, making them suitable for home protection. In spite of the cartridge’s rather mild nature, its terminal performance has always been impressive. Over the years I have written occasionally about the virtues of the .357 Magnum in rifles, and as a result, readers have shared their positive experiences with it on deer, black bear and even elk. I even have letters from hunters and professional hunters who have used them in Africa with exceptional results on a variety of game, including large antelope. Heavy, nonexpanding, deeply penetrating bullets were used with shooting distances kept within reasonable limits. To be clear, I am not promoting this cartridge as suitable for larger species of big game; however, with the correct bullets and proper shot placement, it is a truly potent small cartridge.

Other benefits include long barrel life, lower ammunition costs when compared to .30-30 Winchester, and long case life. Handloaders will appreciate the low powder charge weights, overall efficiency and the option to use either cast or jacketed bullets with great success.

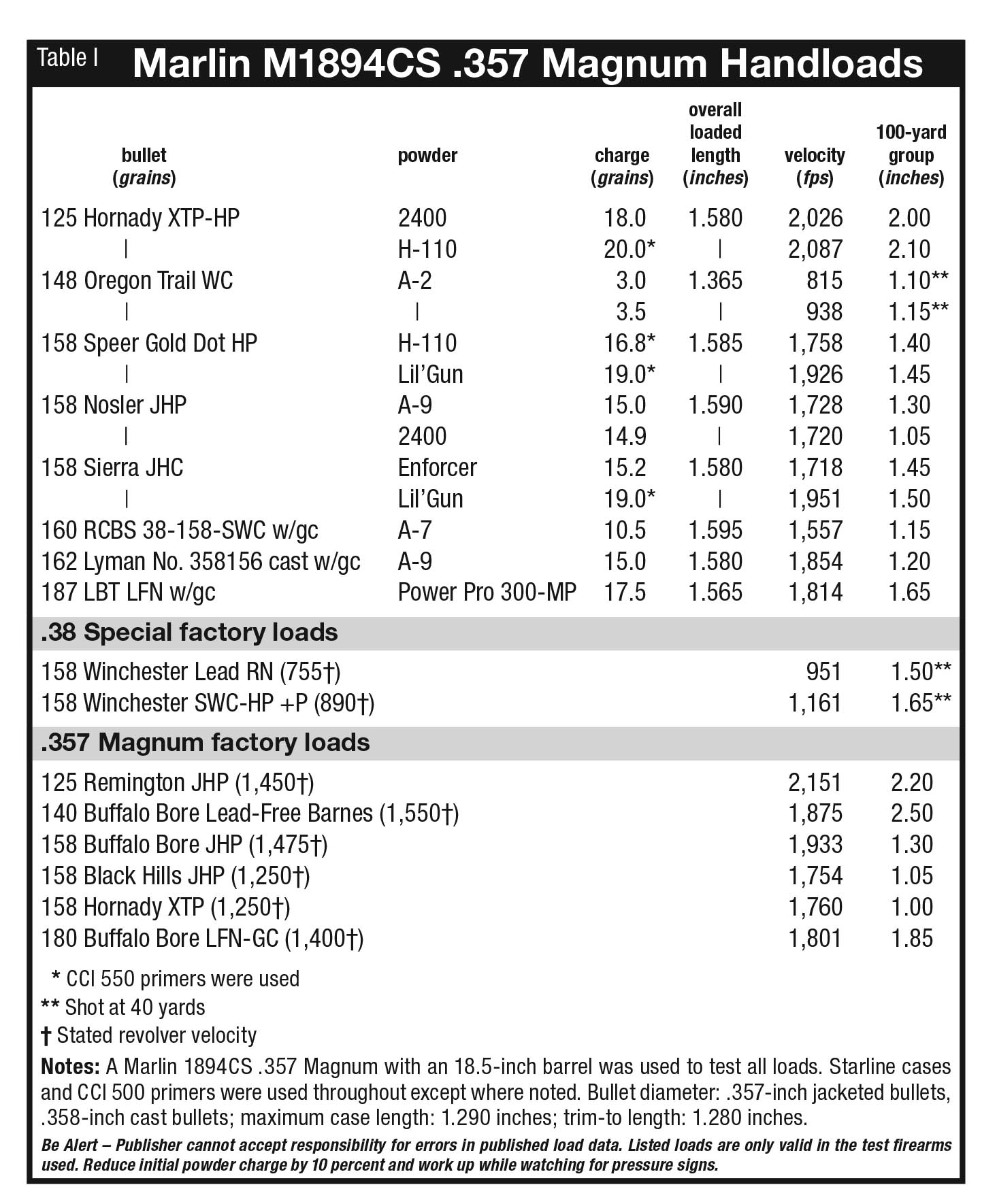

While .357 Magnum 158-grain jacketed bullet factory loads usually chronograph between 1,700 to 1,800 fps, select loads can reach 2,000 fps from an 18.5-inch barrel, or over 2,100 fps from a 24-inch barrel, which can be duplicated with handloads. Most .357-caliber, JHP-style bullets are designed for revolvers and expand reliably at velocities as low as 800 or 900 fps. When pushed to 1,700 to 2,100 fps, their expansion is nearly violent, which results in impressive wound channels, especially in soft tissue.

Consider the Hornady 158-grain XTP at a muzzle velocity of 2,000 fps. Hornady states this bullet will expand at velocities as low as 700 fps, but to be on the safe side let’s say it’s 800 fps. At 700 yards this bullet is still traveling 799 fps, which is way beyond any practical distance the .357 Magnum cartridge will be used – other than impromptu targets while plinking. Very unlucky coyotes have been shot with this bullet at distances out to 300 yards and beyond, which is essentially twice its normal effective range. Jacketed hollowpoint bullets, such as the Speer Gold Dot HP, Hornady XTP and Nosler JHP, provide rapid expansion and devastating wound channels. By comparison, many traditional lever-action cartridges containing cup-and-core bullets with lead flatpoints, such as the .25-35, .30-30, .32 Special, .35 Remington and .38-55, struggle to achieve expansion when velocities drop below 1,700 to 1,800 fps. When fired from the ever-popular carbines with 20-inch barrels, they typically fall at least 200 fps short of their advertised figures that are usually recorded from 24-inch barrels. As a result, reliable expansion often becomes problematic within relatively short distances.

Yet another benefit is the option to use very low recoiling, low velocity (typically between 900 and 1,000 fps) .38 Special 158-grain lead roundnose loads for low-cost plinking or hunting small game. A knowledgeable handloader can improve upon the accuracy of these loads using cast bullets to obtain ragged-hole groups at 40 yards from a good rifle. Discounting the cost of cases, if time is taken to cast your own bullets, these loads can be assembled for a cost similar to .22 Long Rifle ammunition.

Because of rigid standards for feeding and accuracy, Marlin’s new Model 1894CS .357 Magnum carbine has been in the design, testing and re-engineering category for more than four years. In comparing my sample gun with several previous models dating back to 1979, and as late as 2009, there are a few notable external changes. These include a rubber recoil pad, a slightly longer length-of-pull and six lands/grooves rifling. It should be noted that early .357s featured Micro-Groove rifling, while Cowboy and Cowboy Limited Carbines were equipped with six-groove, Ballard rifling, which was also used on late-production carbines. The barrel diameter at the muzzle has been reduced slightly from around .650 inch to .610 inch.

Other than these changes, the 1894CS retains the same 18.5-inch barrel, folding semibuckhorn rear sight and hooded bead front, checkered American black walnut stock and straight lever. Weight is just under 6 pounds.

Next, the Marlin was put through its paces to test function, reliability and accuracy. After firing around 25 rounds, a new Leupold VX Freedom 1.5-4x 20mm scope was mounted in QR bases and rings, allowing it to be instantly detached without tools to allow the use of the open sights. The lightweight, compact scope is a natural for this rifle, and offers plenty of magnification for the distances at which this rifle will normally be used.

A variety of factory loads were tested from Black Hills, Buffalo Bore, Hornady, Remington and Winchester, as well as a number of handloads. It did not take long to realize that this little carbine offered excellent accuracy, exceeding several of my vintage Marlins produced in the New Haven plant. For example, at 100 yards, two loads grouped around one inch (four shots), including Black Hills’ 158-grain JHP and Hornady’s 158-grain XTP loads. Buffalo Bore’s 158-grain JHP load produced one group that was just over 1.25 inches.

Switching to handloads, the 1894CS again produced similar accuracy. Using Sierra 158-grain JHC bullets with 19.0 grains of Hodgdon Lil’Gun powder and CCI 550 primers in Starline cases, velocity was 1,951 fps, and groups hovered around 1.5 inches. Switching to the Nosler 158-grain Sporting JHP bullet, and changing the charge to 14.9 grains of Alliant 2400 powder ignited with a CCI 500 primer for 1,720 fps, groups hovered around one inch. With 160-grain cast bullets from RCBS mould 38-158-SWC (with gas check) sized to .358 inch, 10.5 grains of Accurate No. 7 provided 1,557 fps with groups hovering around one inch.

Most factory .357 Magnum loads contain jacketed or cast bullets with a roundnose flatpoint or truncated flatpoint design, all of which fed perfectly. The above mentioned .357 Magnum handloads containing a SWC bullet profile also fed without a hitch. A number of .38 Special loads were tried in RN and SWC-HP configurations, and they likewise fed without issue. I even assembled a quantity of .357 Magnum cartridges with Oregon Trail 148-grain wadcutters with an overall length of 1.365 that fed flawlessly.

The only small hitch occurred when loading cartridges through the loading gate, which would occasionally bind. By simply holding cartridges in line with the magazine tube, then pushing the nose directly in, cartridges loaded with ease. Keep in mind that this sample rifle is a preproduction version, and company sources assure me that this small glitch will be corrected with production versions.

The 1894CS was disassembled and studied. There are some very minor engineering changes, but the design has remained largely unchanged. Internally the machining is good and in many respects held to tighter tolerances, and is smoother than guns produced in New Haven.

Dealers tell me the Marlin .357 is in high demand and that they can sell every gun that they can get their hands on. This is understandable, as they offer economy, versatility and are especially fun. With an MSRP of $788.62 and street prices well below that figure, the 1894CS is indeed good to have back in production.

Grizzly Custom

1895SBL .45-70

The 1895SBL has earned a loyal following and strong sales. It is quick handling, and the .45-70 cartridge offers considerable punch, especially when stoked with +P loads from Buffalo Bore, Garrett Cartridges of Texas or handloads. It has proven capable of cleanly taking all North American game, including the great bears of the north, as well as all African game with correct loads and bullets. It can also serve admirably for home protection, as it handles similarly to the compact scout rifles but offers faster repeat shots and big-bore authority.

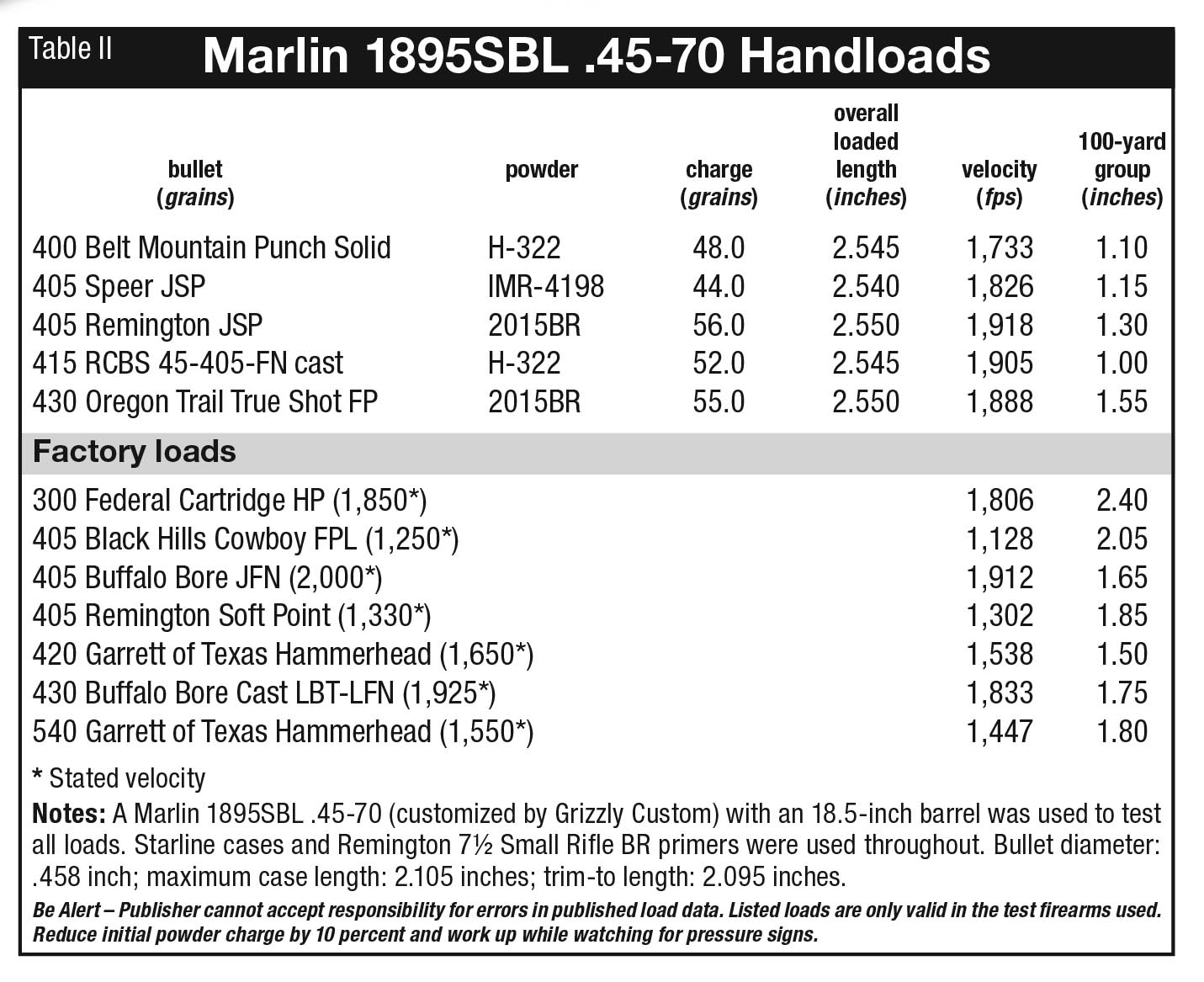

In my personal firearms rack rests a prototype Model 1895SBL that dates back to around 2008. It has been a good rifle and has been used on big game, including bears. While select loads have produced groups of around one inch at 100 yards, it more commonly produces groups of around 1.25 to 1.50 inches.

Recently I was discussing Marlin leverguns with Lew Bonitz of Grizzly Custom Guns (www.GrizzlyCustom.com), and he explained the difficulties associated with having a large back log for custom work performed on Marlin rifles. One of the most popular requests is a complete tune up of the Model 1895SBL. Rather than having a customer’s rifle for a couple of years, he now purchases a “batch” of 1895SBLs, then processes them with the most requested features and work and sells them on his website. He graciously forwarded an example for this review.

The hammer has been reshaped and bobbed, the trigger is straightened, deburred and rounded, then both are finished in black CERAKOTE. The trigger pull has been lightened to break clean at 3 pounds. The large lever loop has been dehorned, as has the action internally and externally, which is then polished to match the orig-inal factory finish. The loading gate has been polished and modified for slick-as-a-whistle cartridge loading while the magazine follower is changed to stainless steel. The stocks are bedded to increase rigidity and possibly improve accuracy. The buttstock is also fitted with a through-bolt to add strength, which is important when shooting a steady diet of heavy loads. The sample rifle came with an optional Leupold FX-II 2.5x Scout scope installed in Leupold QRW rings.

Grizzly Custom’s work is top notch. I was especially pleased that the action retained a mainspring strong enough to reliably ignite all primers, as this is a business rifle that will get used on heavy and potentially dangerous game; it must always fire.

With the aid of sandbag rests, with my left hand resting between the sandbags and the forearm and holding it rather firmly, a variety of factory loads were checked for accuracy. Most proved capable of around one-inch groups at 100 yards, at least as long as I would do my part.

What impressed me most was the smooth, flawless loading, feeding and firing of this custom rifle. After initial test firing was completed, a significant number of rounds were fired from the off-hand position just for fun. It seemed that the rifle almost did the work for me! When holding the rifle on target, just as the scope’s crosshairs or aperture sights were aligned, the trigger broke instantly and seemingly without physical effort. This resulted in an extremely high number of dead-center hits from the offhand position.

The Marlin 1895SBL is a fine field rifle that carries an MSRP of $1,146; however, with the above Grizzly Custom work it sells for $1,995 (without a scope) and is a much improved rifle that is ready to go right out of the box.