Remember the Basics

Troubleshooting Rifle Ailments

feature By: John Barsness | September, 17

Fortunately, new Remington 700 barrels are common and “affordable,” thanks to rifle loonies who buy 700s to turn their actions into custom rifles, selling the factory stocks and barrels. I bought a new stainless .204 barrel for $80 from an Internet site, screwed it on and found the headspace was within specifications. Unfortunately, the silver barrel made the “Tupperware” stock unbearably ugly, so I searched the Internet again and found a walnut stock from a 700 CDL for $100.

Long experience had convinced me that scopes were the most common reason for rifles to start grouping erratically. The 3-15x 42mm Weaver Super Slam on the .204 Ruger had worked perfectly for years, tracking precisely when dialed up and down for shooting prairie dogs out to 600 yards – but they were hard years.

I felt mournful, partly because the Super Slam had worked so well for so long, and partly because I didn’t want to spend money on another scope. The following day, I decided to run a reticle-tracking test with a collimator. The Weaver tracked perfectly, suggesting the rifle itself was probably the problem. When starting to take the stock off to check the bedding, the action screws were found to be a little loose.

Well, Duh! The stock had been purchased from a guy living in a state south of the Mason-Dixon line, where it is very humid, and after a cold winter in Montana, the wood had shrunk. I tightened the screws and returned to the range, where the rifle shot tiny clusters.

Here it should be mentioned that not all action screws should be really tight. Some bolt rifles have a third screw between the standard pair at the front and rear of the action. If really tightened, the middle screw can bend the action slightly, causing accuracy problems. The most common actions with middle screws are Winchester Model 70s with two-piece floorplates and Remington 700s with ADL-style blind magazines. In both rifles, the middle screw simply holds the front of the trigger guard in place, so it should be just tight enough to do that, and no more. If nervous about the middle screw backing out, apply a little blue Loc-Tite to the threads.

Other screws that shouldn’t be really tight are those on scope-mount rings. They should be slightly snugger than middle action screws, but not much, because a scope is essentially a thin tube containing many parts. Reef on the ring screws, and the scope tube can be slightly crushed, upsetting the relationship of the moving parts inside. The range symptoms of overly tightened ring screws often resemble those of loose action screws, but I’ve also seen overly tightened ring screws turn variable-power scopes into fixed powers, and even break reticles.

In the case of the .204 Ruger “parts-rifle,” there were a couple of excuses for jumping to an incorrect diagnosis. It had been a while since I had first acquired a walnut stock from a soggy section of America. Second, over the decades, 17 different brands of scopes (not just individual scopes) have failed while on my rifles, so it was natural to suspect the scope when accuracy went sour.

However, when there’s any mechanical trouble, “Rule No. 1” is to check the basic stuff first. Replacing a scope without first checking screw tightness is like automatically replacing your pickup’s battery when the engine won’t turn over. Instead, check the battery cables.

I asked about some basic stuff, including (yes) checking the action screws or trying another scope. He had rechecked the screws more than once and already tried another scope, so I suggested checking the stock bedding from the forend to the magazine box – he had done that, too. Finally, I suggested the rifle might be possessed. He found my comment only mildly amusing and said he might trade the .30-06 in on something else.

Six months later he contacted me again, saying that after “safe- curing” the rifle for a while, a new thought occurred to him: Both scopes he had tried were brand new. He mounted a well-proven 4x scope, and the rifle shot under an inch with the same load. One of the subrules of rifle diagnosis is to never mount a brand new scope on a brand new rifle, because if accuracy is poor, it is not known whether the problem is with the rifle or scope.

Shooters of a certain age often assume there is something wrong with the rifle, not the scope, because many of them grew up when new rifles often needed “tweaking,” and scopes were so simple they usually didn’t cause any trouble. Fifty years ago, most hunters used fixed-power scopes, usually 4x, and you almost never heard of a 4x Leupold, Redfield or Weaver acting up.

Still, I always check out new rifles, because sometimes basic things can be wrong. I first pull the bolt to see whether all the locking lugs are seating in their recesses. This can usually be determined by looking closely at the rear surface of each lug. If it shows no wear, then that particular lug isn’t seating at all. Such rifles sometimes shoot okay, but sometimes they group as erratically as rifles with loose action screws.

Most trouble with new rifles occurs in the forend. Modern synthetic stocks are supposedly stable – bypassing the tendency of wood to shrink and swell with moisture – but can still shift enough to cause problems. The forends of inexpensive, injection-molded stocks are often so bendable that, even when the barrel is supposedly free-floated, the stock can make contact with the barrel during firing.

Back when wood was the only stock material, forends were pretty stiff – which is why the basic technique for testing a free-floated barrel was sliding a folded piece of paper between the barrel and forend. If the paper slid easily all along the forend channel, the barrel was adequately free-floated.

With the increased flexibility of some synthetic stocks, a better test is squeezing the barrel and tip of the forend in your hand. If the forend touches the barrel, it isn’t floated enough. Luckily, this is easily solved in a couple of minutes with a round wood rasp, another basic solution. Some riflemen prefer more complicated solutions, including stiffening a floppy forend by filling it with epoxy bedding compound and cut-down, graphite arrow shafts. (Exactly why this might be preferable to rasping off a little plastic, I don’t know.)

Many shooters also assume any expensive synthetic stock is impervious to warping. This is us-ually true, but not always. One of my custom rifles has a “lay-up” synthetic stock made by a highly-regarded company. It is constructed of various synthetic fibers inside oven-cured epoxy. I decided recently to change the scope on the rifle so took it from the safe, inadvertently grabbing the tip of the forend and barrel. For whatever obsessive-compulsive reason, I squeezed the forend tip and found it already in firm contact with the “free-floated” barrel. I ended up rebedding the action to refloat the barrel – so no, we can’t totally assume synthetic stocks are always more stable than wood.

Another “basic” many shooters forget is cleaning any part of a rifle other than the bore. When I first started shooting, many guys obsessively cleaned their entire rifle every time they shot it. Today, however, there are so many reasons not to clean rifles, many shooters don’t clean them very often.

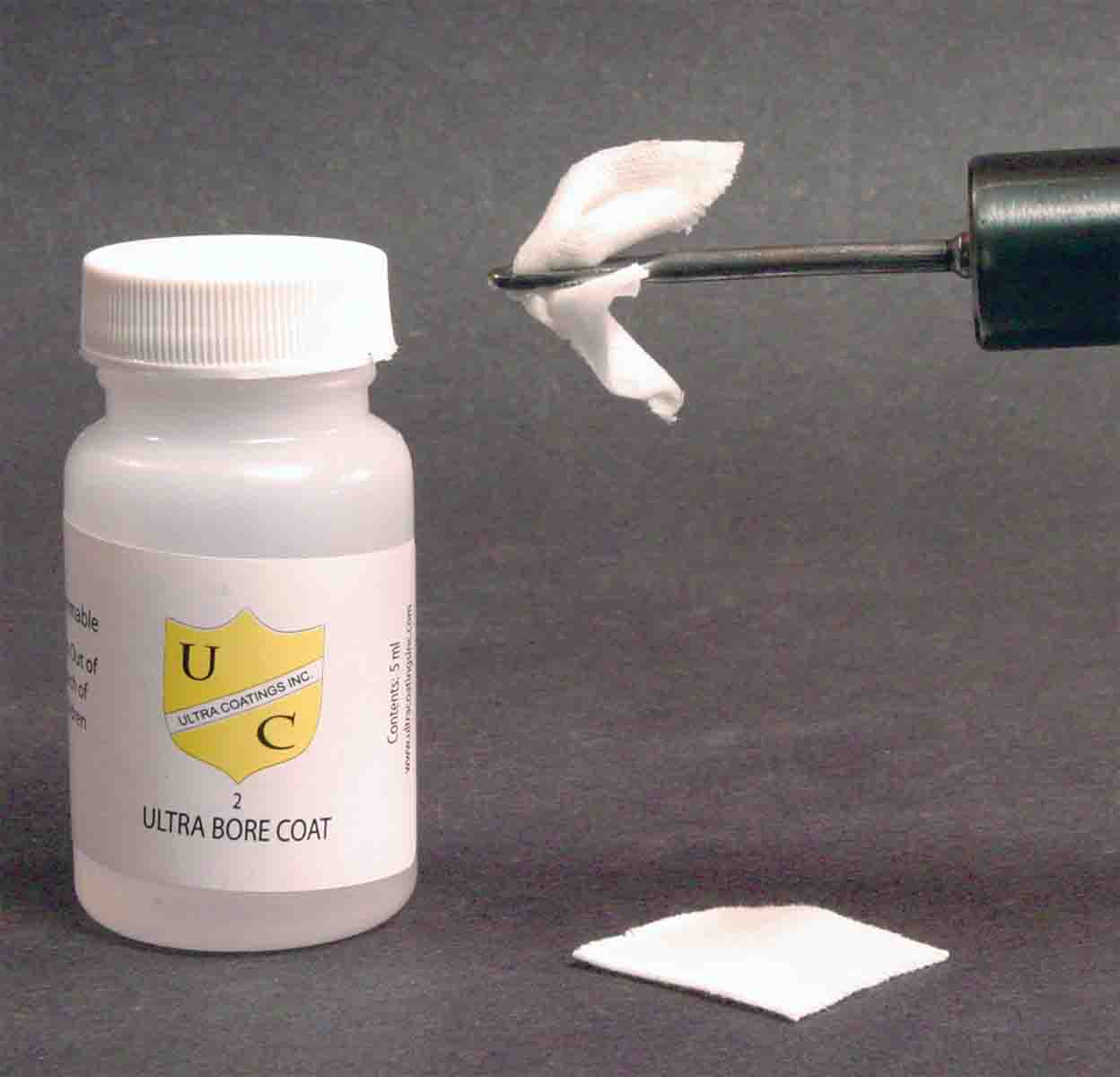

Stainless steel barrels weren’t unusual on hunting rifles a generation ago, but today they’re common, and theoretically don’t rust. I say “theoretically,” because the stainless alloys used in most barrels can still rust when exposed to salt, whether in seacoast air or a saddle scabbard thoroughly salted by sweaty horses. Aside from stainless steel, there are now bore treatments that practically eliminate bullet jacket fouling, and more powders contain decoppering agents.

When bores used to be cleaned far more frequently, most shooters also cleaned and oiled the action, but these days many shooters (including me) sometimes don’t clean the bore for hundreds of rounds. Meanwhile, gunk builds up in the actions from dust and moisture, and tiny bits of cartridge brass stick to the bolt face, often around the extractor or ejector. Eventually the rifle’s action malfunctions in some way; sometimes the issue is as basic as the bolt not sliding easily, and sometimes it’s as serious as the extractor breaking. Even if a stainless barrel – treated with DYNA-TEK Bore Coat and only shot with decoppering powders – shoots accurately for hundreds of rounds, it helps to clean the action more frequently, including the bolt face.

Most Americans live in metropolitan areas, where it is difficult to get to a range very often, so forget basics, such as following through – maintaining consistent contact with the rifle until the bullet hits the target. This can be something as small as what my friend Tim Fallon, owner of the FTW Ranch in Texas, calls the “booger flicker,” flipping our forefinger off the trigger as soon as the firing pin drops.

Even the impact of the front sling swivel stud on the front shooting bag can cause a “flyer,” yet many shooters place the forend on the rest so the stud is right in front of the bag. Remember, when recoil begins, the bullet is still in the bore, and any little inconsistency in the rifle’s position can affect the bullet’s flight.

Thanks to field-adjustable turrets, these days many scopes have stronger adjustment springs, but some can still require a little help. One common trick is to turn the turrets a few clicks beyond the preferred adjustment point, then back again, but hesitant adjustments can often be fixed by turning the turrets completely through their adjustment range a few times. This often prevents problems with new scopes and can even help well-used scopes. I have a turret scope on a CZ .17 HMR, but on the first rodent shoot last year it acted weird. Eventually, I had another Duh! moment and took a minute to whirl the elevation adjustment up and down a few times. After that, the scope behaved itself.

None of these basics are as fun to discuss (or obsess over) as buying a 6.5 Creedmoor or $1,200 scope, but they can make far more difference in the success or failure of our shooting.