Light Gunsmithing

Loose .22 Rimfire Stocks

column By: Gil Sengel | March, 19

Unfortunately, due to fierce competition among makers, anything that will lower production costs on these little rifles has been tried. One such change is that most bolt actions and semiautomatics with one-piece stocks made in the last 100 years only have a single machine screw holding the barreled action in the wood. This allows looseness to develop in the assembly. Even a slight amount can affect trigger pull. Then there is degraded accuracy that may not be so obvious on rifles with open sights but becomes noticeable on rifles with grooved receivers that allow scope mounting. Can this looseness be eliminated by just turning the one screw tighter? In a word – no. In fact, more problems can be caused by overtightening.

Add to this the fact that barrels and receivers are round and of nearly the same size. Stock inletting includes just a round-bottomed groove that is slightly larger than the parts, so no further work is needed. They do not fit too well.

Next, rimfire receivers are made without recoil lugs, so the single assembly screw simply threads into the bottom of the receiver or barrel. Often a small block is either silver soldered or dovetailed into the receiver or barrel to provide more thread length for the screw to access, but these never precisely fit into the stock. There is nothing to prevent longitudinal movement of the barreled action except turning the one

Fortunately, this poor fit can be corrected with the use of a bit of epoxy bedding compound. An example is the Winchester M69A that has a round block for the takedown screw dovetailed into the barrel. Usually these fit their recess in the stock fairly well when new, but they can become quite sloppy due to soft wood or oil soaking and shrinkage due to age. This is especially true of anchor blocks that are square or rectangular and did not fit well when new.

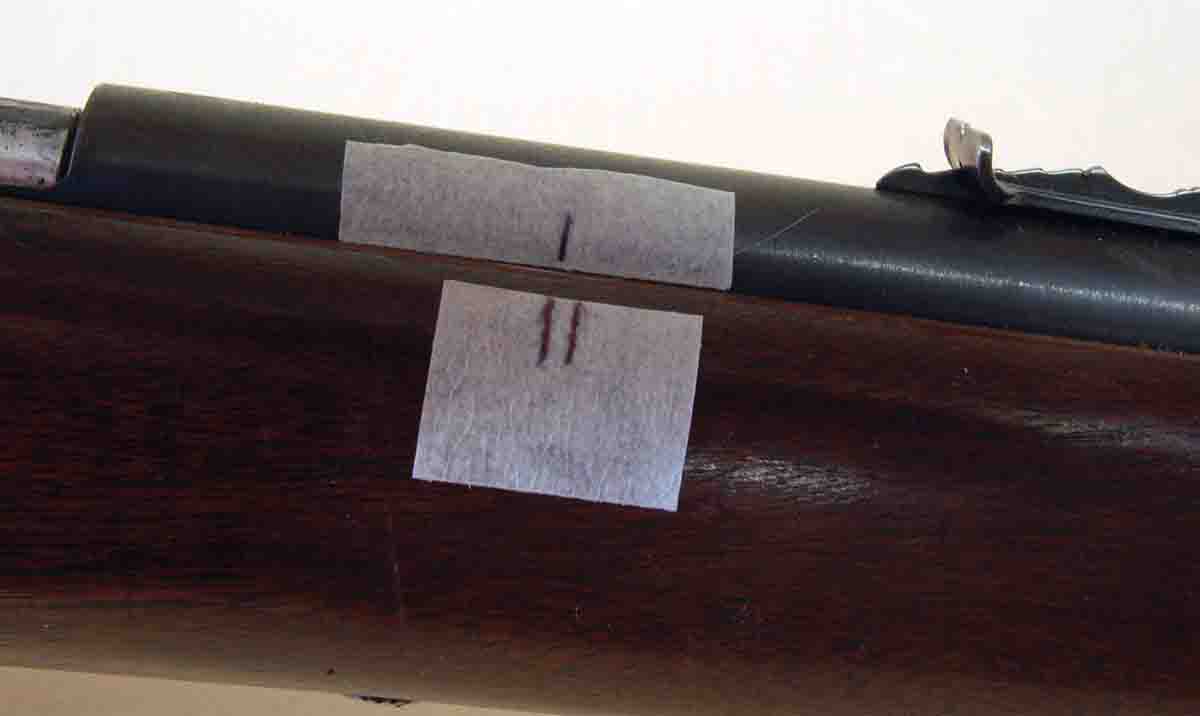

If more than just the block is bedded, this should be done in two stages, with the block first. Rough-up the bottom of the block cavity a bit using a Dremel tool or chisel – just enough to allow the epoxy to bond to the wood. Next, coat all the metal surfaces and threads (both internal and external) with paste wax. Mix up epoxy bedding and place enough in the stock recess to come up on the block just a bit, or full length if the receiver and barrel will be bedded later. Be certain to place modeling clay in recesses around where the block attaches to the barrel or receiver. Fail to do this correctly and the epoxy will mechanically lock the wood and iron together forever!

When placing the barreled action into the stock, turn the screw only until it begins to offer resistance. This will guarantee the barreled action is in perfect alignment with its assembly screw and the barreled action is not being bent. After the epoxy has hardened and the rifle is disassembled, it may be necessary to scrape the sides of the block cavity a tiny amount to assure easy reassembly. All anchor blocks are handled the same way, whether round or square, attached to the barrel or receiver.

The other method of attaching metal to wood on older rimfires is directly threading the screw into the receiver using no anchor block. There is nothing to bed in epoxy to prevent looseness. Care must be taken here because too much tightening can strip the threads in the receiver.

The solution, however, is quite simple: Use the assembly screw as a recoil lug! A steel tube is made and fitted exactly as in pillar bedding a centerfire rifle, but with one difference. The inside diameter of the tube is made exactly the same as the outside diameter of the screw. When assembled, the barreled action is held in the stock with no looseness possible, and the screw needs only a light touch with the screwdriver.

Repairing loose stocks on .22 rimfires is a worthwhile project for anyone interested in gun work. There is also no shortage of such rifles. Winchester made at least 3.1 million, Remington 4.2 million, and the hardware store brands produced by Savage/Stevens, H&R, Iver Johnson, Mossberg, etc., probably accounted for as many more even though no one was counting. These repairs help preserve the little rifles by making them more desirable and useful for generations to come.