Mark V Altitude

A New .257 Weatherby Magnum

feature By: John Haviland | May, 19

About 90 percent of the plant will be dedicated to manufacturing, and Weatherby wants to bring the majority of the production of the Mark V in-house, according to Luke Thorkildsen, Weatherby’s vice president of sales, marketing and product development. That is quite a mandate considering Weatherby currently offers about 35 models based on the Mark V. The Mark V recently received some refinements to its stock, a new trigger and a sub-MOA guarantee to shoot three bullets under an inch at 100 yards. I’ve been shooting one of the new models, a Mark V Altitude .257 Weatherby Magnum.

“A wood stock is classic Weatherby,” Thorkildsen said. Fiber-glass and composite stocks, though, are starting to edge out wood as the most popular stock material.” In fact, of all the Mark V models, only five feature a wood stock.

The Altitude’s composite stock is made of laminated carbon fiber by Bell and Carlson and weighs 25 ounces. Weatherby applies a Kryptek Altitude camouflage pattern. An aluminum bedding block is molded into the stock. Two pads in the barrel channel, about an inch back from the forearm tip, apply some upward pressure on the barrel. The forearm is a long 11 inches and is stiff as a pry bar. A one-inch thick Pachmayr Decelerator recoil pad caps the butt.

Thorkildsen said the Mark V was designed before the advent of CNC machines and can be difficult to manufacture. Its one-piece bolt is more costly to make than bolts assembled with a separate handle and head. “The Mark V we call the Magnum is tricky to make because of its nine locking lugs,” he said. “But in the end you get a strong and tough action that is very smooth.”

The three rows of three locking lugs around the Mark V’s bolt head have been criticized as imperfectly fitting all of the lugs in their seats. Probably all nine lugs do not make contact with their seats when a rifle is new. I put a dab of pink ink on the rear face of each of the Altitude’s lugs and closed and opened the bolt. The ink was worn-off the face of three lugs in one row parallel to the bolt, and one lug in another row. After the rifle had been fired about 50 times, ink was reapplied to the lugs. It had worn-off of all but one lug after firing one cartridge in the rifle.

The bolt head is slightly smaller in diameter than the bolt body. The bolt raceway in the receiver is slightly larger in diameter than the bolt body so the bolt travels smoothly back and forth due to a tight fit slightly forward of the tang and inside the rear of the receiver bridge, and eight straight flutes in the body reduce friction. The bolt is kept from turning and binding by a bolt release stud running in a cut in the underside of the raised bolt. Bolt lift is a short 54 degrees. The full-diameter bolt has become popular in recent years in rifles such as the Ruger American.

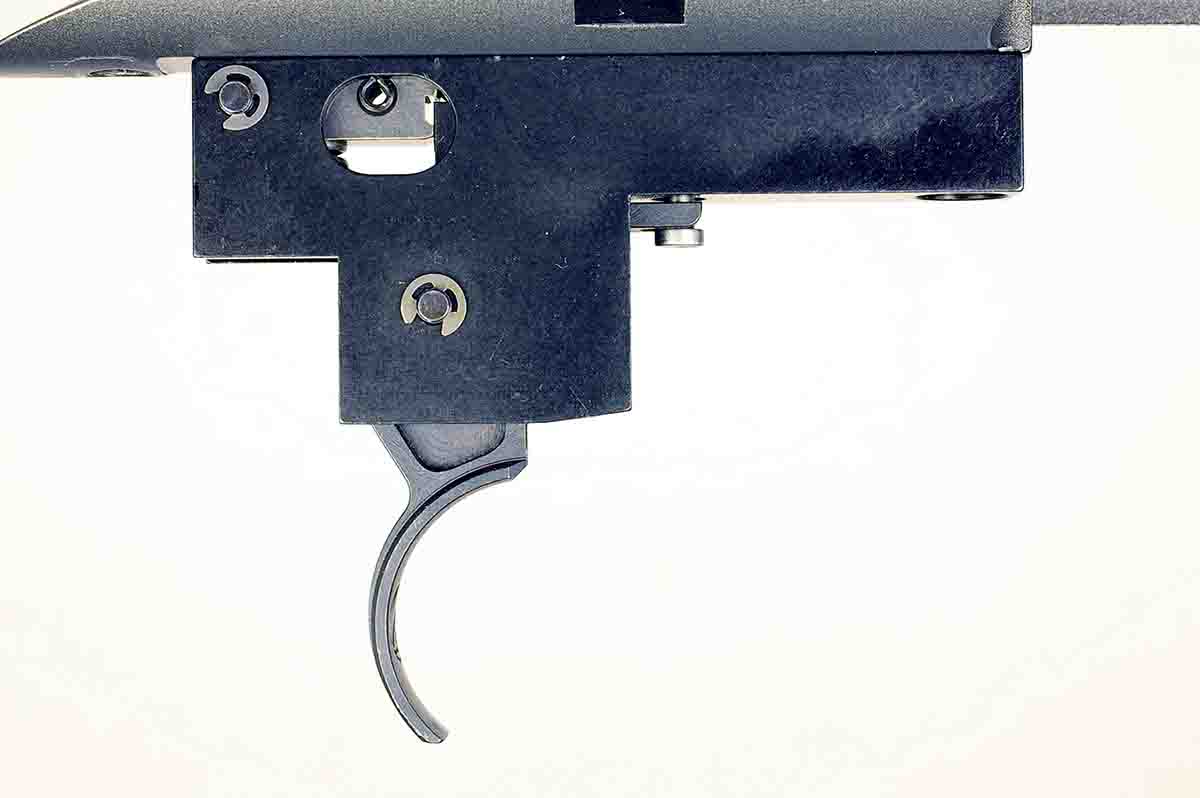

Weatherby designed its LXX trigger for the Mark V several years ago. “It was designed with a single-stage pull and a clean break,” Thorkildsen said. “And it was meant to be adjusted by the shooter.”

The Altitude’s barrel is a standard sporter contour measuring 1.250 inches in diameter at the breach. It tapers over its 26-inch length to .60 inch in diameter at the muzzle. Six straight flutes on the barrel start about 3 inches in front of the action and terminate almost the same distance from the muzzle.

The Altitude’s barrel is made by Criterion Barrels in Germantown, Wisconsin. Criterion uses the button-rifling process. Bores are lapped to remove tool marks. Button rifling stresses steel, so Criterion heat-treats barrels after they have been rifled to relieve stress.

Weatherby suggests a barrel break-in procedure of thoroughly cleaning the barrel after each shot for 10 shots, then cleaning the barrel after firing three shots for 30 shots. I ignored this suggestion and just went about shooting the rifle. I peered into the bore with a Lyman borescope after firing about 50 shots. Rifling lands and grooves looked perfect from the breach to the muzzle, with no tool marks or blemishes. Toward the muzzle, only an inch or so of one land was streaked with copper fouling. The absence of copper fouling was remarkable, considering many of the bullets were fired through the barrel at upward of 3,500 fps.

The Altitude weighs 6.75 pounds. Mounting a SIG Sierra-3BDX 4.5-14x 44mm scope in Burris Signature steel rings and bases brought the weight up to 9 pounds, 10 ounces.

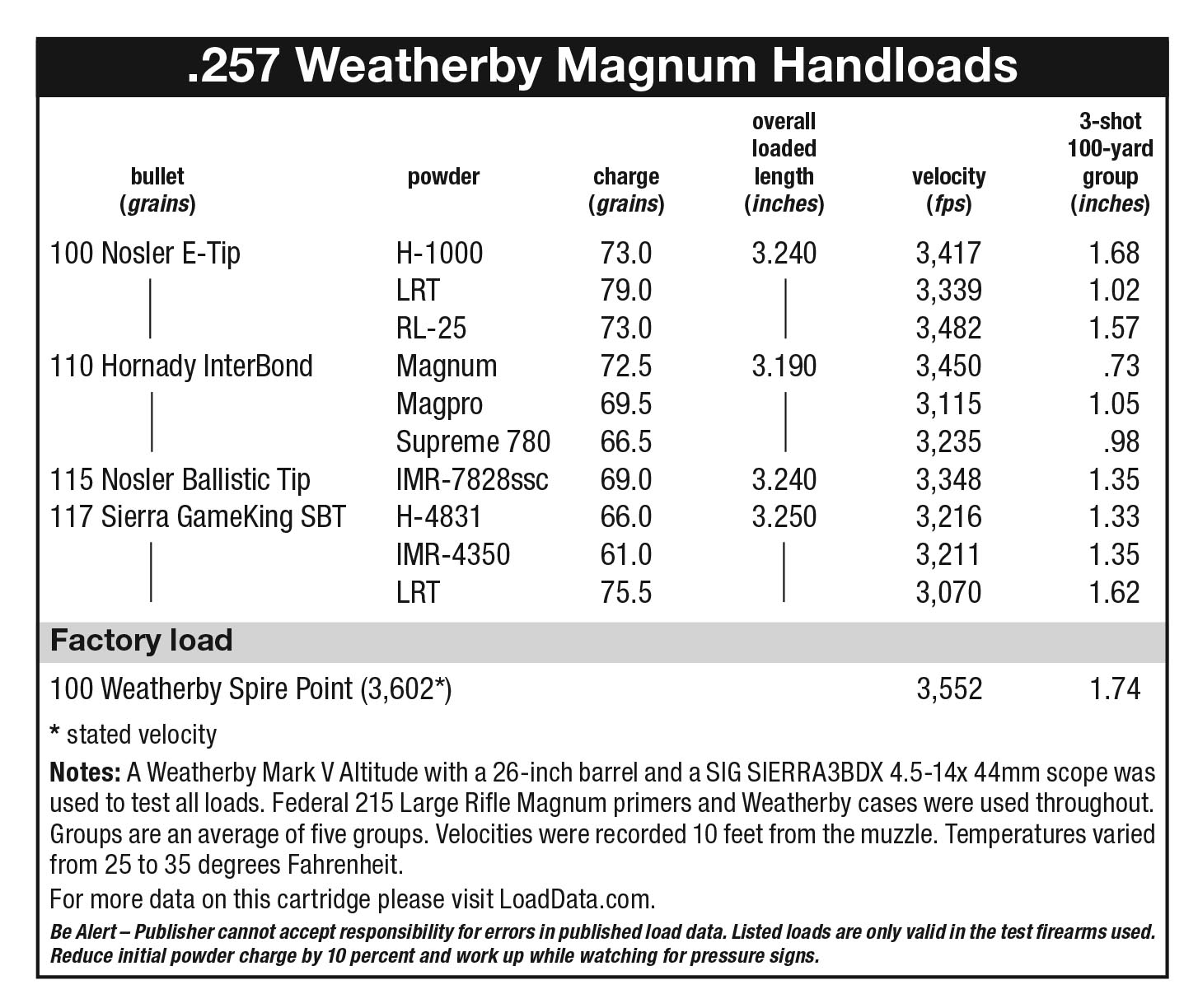

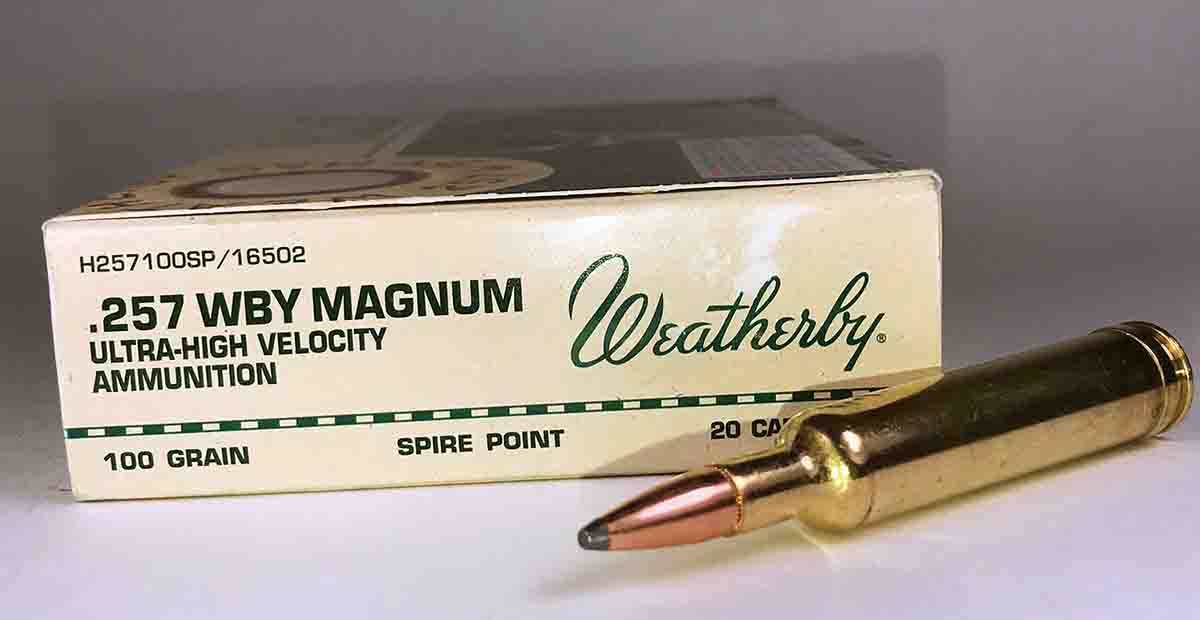

Weatherby’s sub-MOA accuracy guarantee pledges .99 inch or less three-shot groups at 100 yards when used with Weatherby factory or premium ammunition. The Mark V did not quite live up to that promise shooting Weatherby .257 Weatherby Magnum factory cartridges with Hornady 100-grain Spire Point bullets. Three-shot groups measured closer to 1.7 inches. The rifle did shoot three handloaded Hornady 110-grain InterBond bullets under an inch using two different powders, and it came close to an inch with several other handloads. Many groups showed two bullets close together and a third out an inch or so.

The SIG Sauer BDX app was downloaded to my iPhone to configure the ballistic profile for Nosler 115-grain Ballistic Tips fired from the .257 Weatherby Magnum.

Data was transferred to a SIG KILO BDX rangefinder and on to a SIG Sierra3BDX scope on the Altitude. Ranging a target with the BDX rangefinder displayed an illuminated aiming dot in the scope that compensated for bullet drop and drift out to 800

Burning 70-some grains of powder per shot quickly heated up the Altitude’s barrel. After nine shots, mirage boiling up from the barrel made the scope’s reticle look like it was swimming. The barrel quickly cooled, though, perhaps aided by the increased surface area created by the flutes on the barrel. The thin barrel must whip some when a bullet is pushed through the bore in front of enough powder to fill the .257’s big case. The two pressure pads in the stock’s barrel channel are designed to reduce that whip.

Headspace for the .257 Weatherby is set by its belt. Like many factory cartridges with a belt, .257 Weatherby Magnum cartridges are very short at the shoulder. Factory cartridges were .018 inch shorter at the shoulder compared to the shoulder of once-fired cases. Cases would soon split in circumference in front of the belt if their shoulders were pushed back to their original position every time they were sized. My Redding sizing die was adjusted to set headspace on the case shoulder.

The Weatherby’s chamber has a long throat length of .378 inch, or “free bore” as Weatherby calls it, to give a bullet a running start before it engages the rifling to somewhat reduce pressure. A cartridge length of 3.393 inches would be required for Sierra 117-grain GameKing SBT bullets to touch the beginning of the rifling. However, a cartridge length of 3.250 inches is about as long as will fit in the rifle’s magazine. At that cartridge length, the Sierra bullets must make an unsupported jump of .143 inch to contact the rifling. Making sure bullets are seated straight in cases and the center of the bore is one way to ensure that lengthy jump does not adversely affect accuracy.

Hornady 100-grain Spire Point bullets in Weatherby factory loads were seated straight in case necks, with only a few out of 20 varying .002 inch. Some bullets in my handloads, though, varied up to .006 inch from straight while others were straight when measured using a Hornady Concentricity Tool. I used the tool to straighten crooked bullets.

Extreme velocity spreads were narrow with many of the loads tested. Weatherby factory cartridges provided an average extreme velocity spread of 23 fps for five, three-shot groups. Hodgdon-4831, Ramshot Magnum, Accurate Magpro and Ramshot Long Range Tactical (LRT) turned in extreme velocity spreads of 8 to 17 fps. When there was a wide swing in velocity it was on the slow side, and that bullet hit lower than other bullets in a group.

Weatherby will completely move into its new headquarters in Sheridan, Wyoming, and will start building Mark V rifles by this summer. Mark V production will have ceased its travels around the world and will have found a permanent home in the shadow of Wyoming’s Bighorn Mountains.