Light Gunsmithing

Big-Bore Plinker Project - Part II

column By: Gil Sengel | July, 17

In the last issue, the major work was completed on a nifty, little plinking rifle built on a Model 91 Mauser action rebarreled to .45 ACP. This time the final details on shooting are covered.

When the military forend was shortened to accommodate the new barrel, it was explained how to determine the proper length. The forend tip would then be rounded off. However, the forend has a rather large hole running parallel with the barrel to hold a cleaning rod. It can be plugged, but an exotic wood tip looks better. Thus, the forend was cut 1.5 inches shorter than calculated, with the length added back by the forend tip.

Proper wood for forend tips is black ebony, either Gabon (Diospyros crassiflora) or the lightly striped Macassar (Diospyros celebica). Import restrictions, however, have dried up supply, pushing prices to ridiculous levels. The wood shown is Wenge (Millettia laurentii), a West African hardwood sometimes called Panga Panga. It is very dark brown with closely spaced black streaks. All hobby wood shops carry it in 1.5- to 2-inch square pieces about a foot long, called turning blocks. These are normally used to make artsy-craftsy things. Wenge looks good and costs 90 to 95 percent less than ebony.

The next item is trigger pull. Most shooters don’t like two-stage military triggers, but there is no replacement available for the Argentine Mauser. Design of the unit also precludes installing a screw to adjust out the first-stage takeup. I don’t recommend such a modification, because people tend to adjust it too far, setting the stage for trouble.

There is, however, a way to modify the M91 trigger, but it is not adjustable. The only component needed is a short, large-headed No. 8 machine screw. Its shank exactly fits the hole in the rear of the trigger return spring housing (see photo). Head diameter must be large enough to allow filling the flat shown, which prevents the screw from turning. Such screws are available at hardware and home improvement stores that sell fasteners.

The photos tell the whole story. Two trigger pins must be removed and a screw fit into the rear of the return spring housing as shown. Mark the rear of the screw with a felt-tip pen (shown in red), assemble the trigger finger piece to the housing and housing to the rifle (a return spring is not necessary). Now push the finger piece forward until it marks the ink. Disassemble it and grind off the contact point. Repeat the process until the front “bump” of the two on the finger piece (see photo) just misses the receiver. The first stage has not been removed, but full sear engagement of the second stage remains, leaving a safe trigger. Place a couple of drops of stock finish under the head of the screw during final assembly, and it will stay in place forever.

The gunsmith who showed me this modification back in the 1970s also clipped .25 inch off the mainspring. Cocking force is reduced a bit, but primer indentation is still full depth. Trigger pull on this rifle is now just under 5 pounds; not bad by today’s standards and fine considering the rifle’s purpose.

Now, regarding sights, the light barrel ruled out common open types and an expensive scope was deemed out of place on a plinking rifle. Besides, I had already found a neat Bushnell Ultra Compact TRS-25 red dot sight. Measuring 2.5 inches long and with a tube diameter of 1.1 inches that only clears its Picatinny rail base by about .050 inch, it mounts as low as physically possible. Weight is only 4 ounces; it is a perfect substitute for open sights.

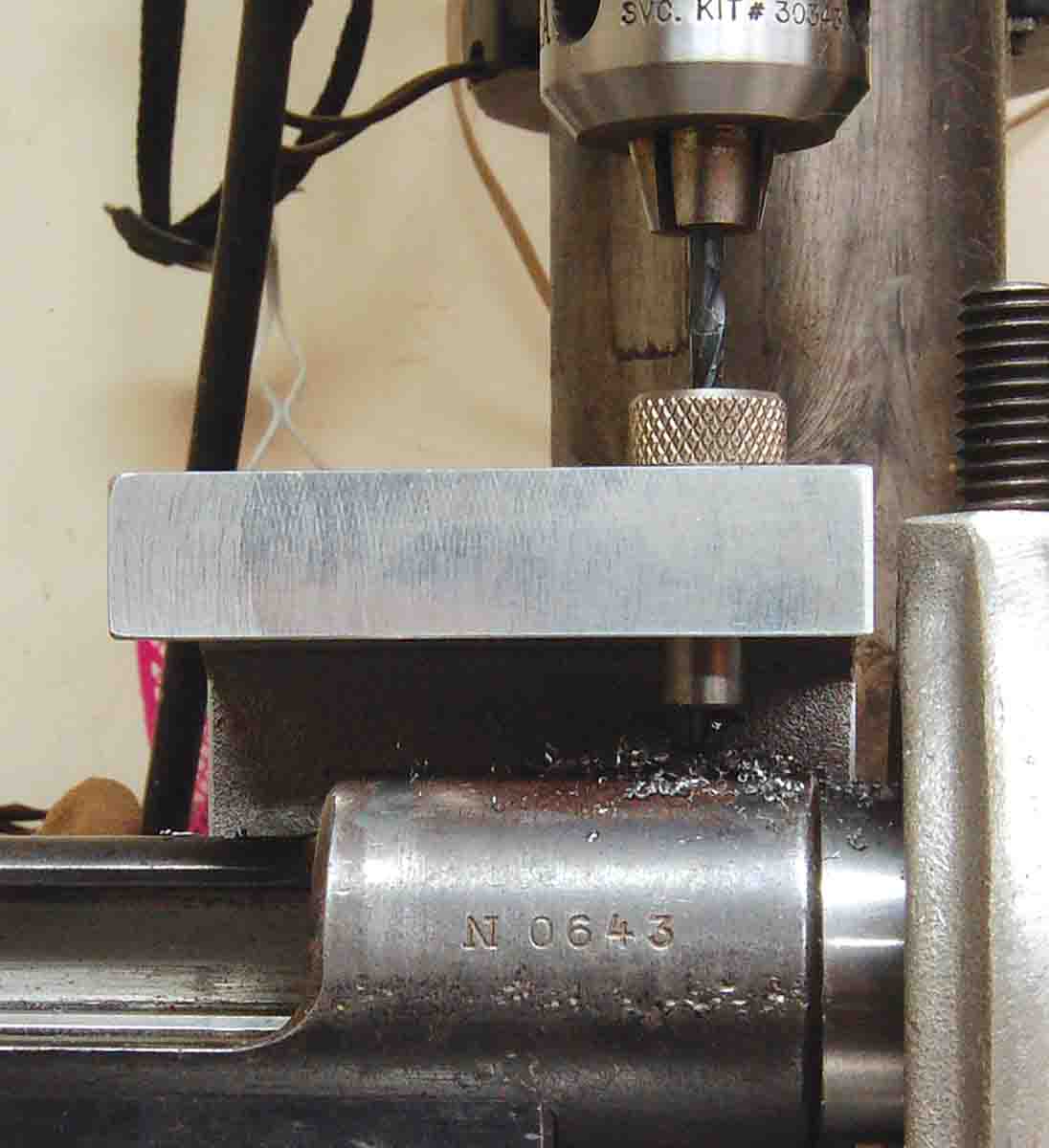

The mount base is a 2.6-inch long piece cut from a section of Brownells Picatinny rail blank, then made as low as possible (.225 inch) while still leaving enough thickness for mounting screws. The rifle’s receiver ring was drilled at the standard Weaver top-mount hole spacing, and the rail section was fitted. A photo shows the result.

As mentioned in the last column, this rifle is a close copy of one I shot many years ago. There is no recollection, however, of ever firing that rifle at a paper target to measure accuracy. Nevertheless, it seemed easy enough to hit cans, steel plates, white rocks, etc., out to 150 yards or so, though hold-over was obviously necessary. The first shots from this rifle were fired indoors at 25 yards, simply because an Oehler M35P chronograph is always set up at that distance. The bullet used was Lyman’s 452374, a standard 230-grain roundnose cast bullet for the .45 ACP. I was not happy with the one-inch groups – bullets from the same casting session shot almost as well from a couple of handguns.

It was planned to use common weights of 185, 200 and 230 grains in jacketed Hornady Action Pistol nonexpanding competition bullets to learn the effect of the longer barrel on velocities. All three could not be found, so the same weights in Hornady XTP expanding slugs were used. The first few groups were no better than the cast bullet groups. Then something strange happened. After about 30 jacketed rounds had gone down the barrel, groups became just one ragged hole. Earlier loads, both cast and jacketed, were reshot with the same one-hole result. Since the barrel was new, free floating and the rifle untouched when the change in group size occurred, I am not even going to guess what might have happened.

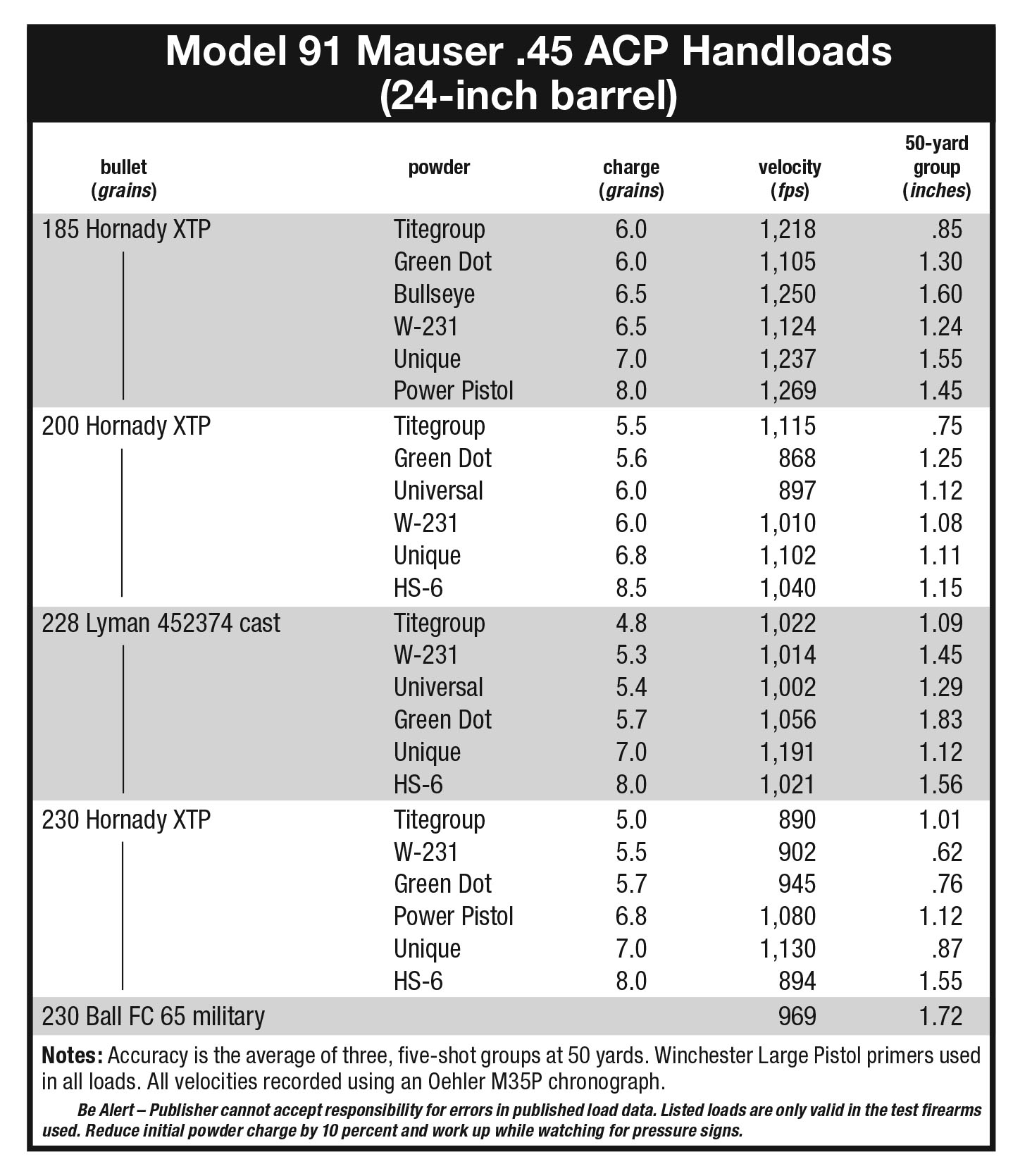

All loads from 5-inch pistol barrels give the Hornady 185-grain XTPs about 950 fps; the 200s about 900 fps; and the 230s near 850 fps. Results shown in the table from the 24-inch barrel of the “plinker” give a good indication of what other combinations will do. Unfortunately, the added barrel length did not quiet the report very much.

To save space, the loading data includes only the average of three, five-shot groups for velocity and group size at 50 yards. Clusters at 100 yards were shot outdoors, where light conditions make precise holding of the nonmagnifying dot sight difficult. Yet 2.75- to 3-inch groups were normal for the 200- and 300-grain XTP with all powders except HS-6, which nearly doubled that. For cast bullets, accuracy was in the 3- to 3.5-inch range. A 6-inch steel plate was set up at 150 yards. With the sight properly adjusted, a hit was obtained with every shot from the two heaviest XTP bullets.

Recoil and noise from the 6.5- pound rifle are low, yet it is very obviously not a .22 rimfire. Kids love it. In fact, it’s hard to get it back from friends who borrow it “for the kids to shoot,” they say. Yeah, right.