Thompson/Center Compass

Testing a Budget-Priced .30-06

feature By: John Haviland | July, 17

Thompson/Center now offers bolt-action rifles at three price levels: the Dimension, Venture and Compass. The Compass is intended to compete with the increasing number of budget-priced bolt actions that have lately entered the market. The Compass comes with a guarantee to shoot one-inch, three-shot groups at 100 yards. That’s a tall order for a rifle with a suggested retail price of $399.

The Compass has several features found on economy rifles from other manufacturers, like a full-diameter bolt with a short, 60-degree lift and three locking lugs, a detachable polymer magazine and basic synthetic stock. The rifle also includes premium features, such as an adjustable trigger, three-positon safety, a threaded muzzle to accept a compensator, muzzle brake or suppressor and a button-rifled barrel with 5R rifling. The Compass is chambered in such cartridges as the .204 Ruger, .223, .22-250, .243, .270, 7mm-08, .308 and .30-06 with 22-inch barrels, and the 7mm Remington Magnum and .300 Winchester Magnum with 24-inch barrels. Rifles weigh 7.25 pounds chambered in standard cartridges, and 7.5 pounds in the two magnum cartridges.

I shot a Compass .30-06 for several months and fired nearly 300 rounds through it at targets and rocks on a hillside. Right from the first shot, the rifle’s action cycled very smoothly. The Compass receiver is basically a cylinder with a full-diameter bolt running through its center. The bolt has little play during cycling, as it is kept aligned by a tight fit inside the receiver bridge and a flat on the bottom of the bolt that fits in a slot in the bottom of the rear of the receiver. It is kept from turn-ing and binding by the head of the bolt release gliding in a cut on the left side of the raised bolt. The wing of the three-position safety is located on the rear of the bolt. It swings smoothly forward from its rear “safe” setting to the middle spot that allows opening the bolt with the safety still engaged, and fully forward to the “fire” setting. The magazine stores cartridges in a semicircle, with the top cartridge in line with the chamber. When the bolt closes, the bottom locking lug strips a cartridge out of the magazine, and the “clack” of a cartridge popping out of the magazine is the only indication of a cartridge entering the start of the chamber. The three-lug bolt head requires a handle lift of only 60 degrees to open. That short arc, though, demands a fair amount of upward force on the bolt handle to break a fired case free from the chamber, cock the firing pin and open the bolt.

Like most new actions, the Compass’s bolt face is recessed to enclose the head of a cartridge case up to the top of the extractor groove. A flat steel extractor slides in a slot cut in the face of the bottom locking lug to engage a case rim when the bolt is closed. A plunger on the opposite side of the bolt face pushes cases or cartridges out of the ejection port when the bolt is pulled rearward.

The Compass receiver ring is bedded in the stock differently than other rifles. Most receivers have a recoil lug integral with the bottom of the receiver ring, or it is sandwiched between the barrel and front of the receiver that fits into a mortise in the stock. The Compass recoil lug is locked in the stock, and the dished out lug fits into a groove in the bottom of the round receiver ring. Tightening the front receiver screw locks the lug and bottom of the receiver together. A .75-inch thick block in the stock between the lug and the magazine soaks up recoil. This block also beds the receiver ring. The receiver, beneath the bridge and rearward to the tang, is also cradled on the rounded inletting of the stock. Both receiver screw holes are bushed.

Thompson/Center says the Compass’s trigger is adjustable from 3.5 to 5 pounds of pull weight. The owner’s manual details how to fine-tune pull weight by adjusting the three nuts on the trigger. I turned the two weight-of-pull adjustment nuts on the trigger to bring its pull down as light as it would go, 3 pounds 11 ounces. The trigger had no creep or overtravel making for an excellent hunting rifle trigger.

The Compass had been shot several times before I looked into its bore with a Lyman Borecam Digital Borescope. Hardly any rifling lands were visible, and I thought I had worn out the barrel. T/C states the Compass has 5R rifling, which has lands with angular edges. This supposedly reduces powder and bullet jacket fouling at the junction of the grooves and lands and causes less bullet deformation.

The black injection-molded synthetic stock is fairly plain. The only trimmings are sling swivel studs, a grip cap with “T/C” in the center of a compass face and a recoil pad. The .75-inch thick, soft rubber recoil pad does a fair job of soaking up .30-06 recoil. The trigger guard molded into the synthetic stock gives the rifle a cost-conscious look. The slender forearm is shaped with a ledge on each side with a row of V-shaped tread for the fingers to grasp. The tread is also molded into the sides of the grip. The straight comb is high enough so the rear of the bolt just clears the nose of the comb, and a cheekpiece on the left side of the butt cradles the cheek of right-handed shooters.

Holding with the Compass’s budget price, I mounted a Redfield Revolution 4-12x 40mm scope in clamp-on rings onto the Weaver-style bases included and mounted on the rifle. The complete rifle weighed 8 pounds, 3 ounces.

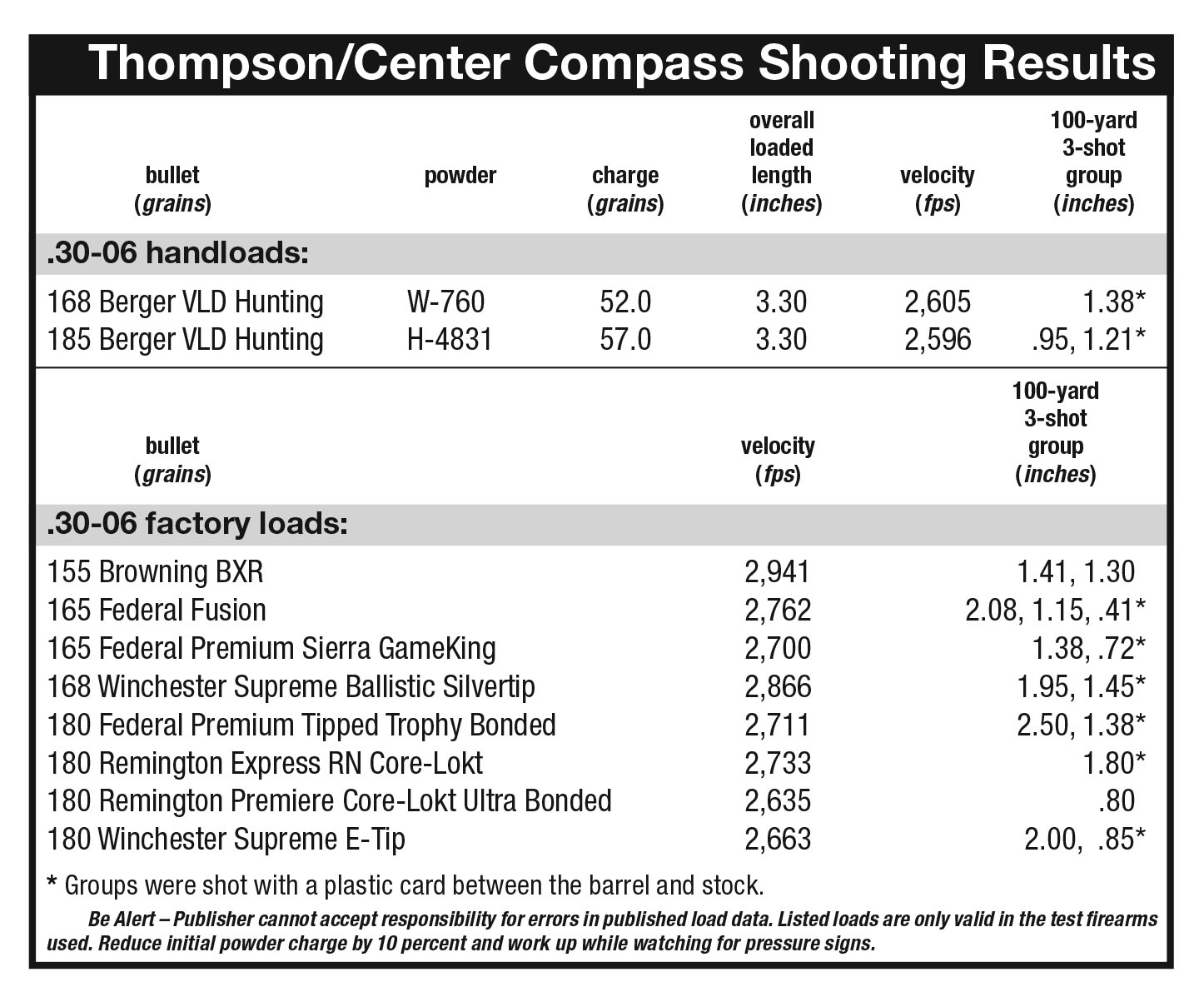

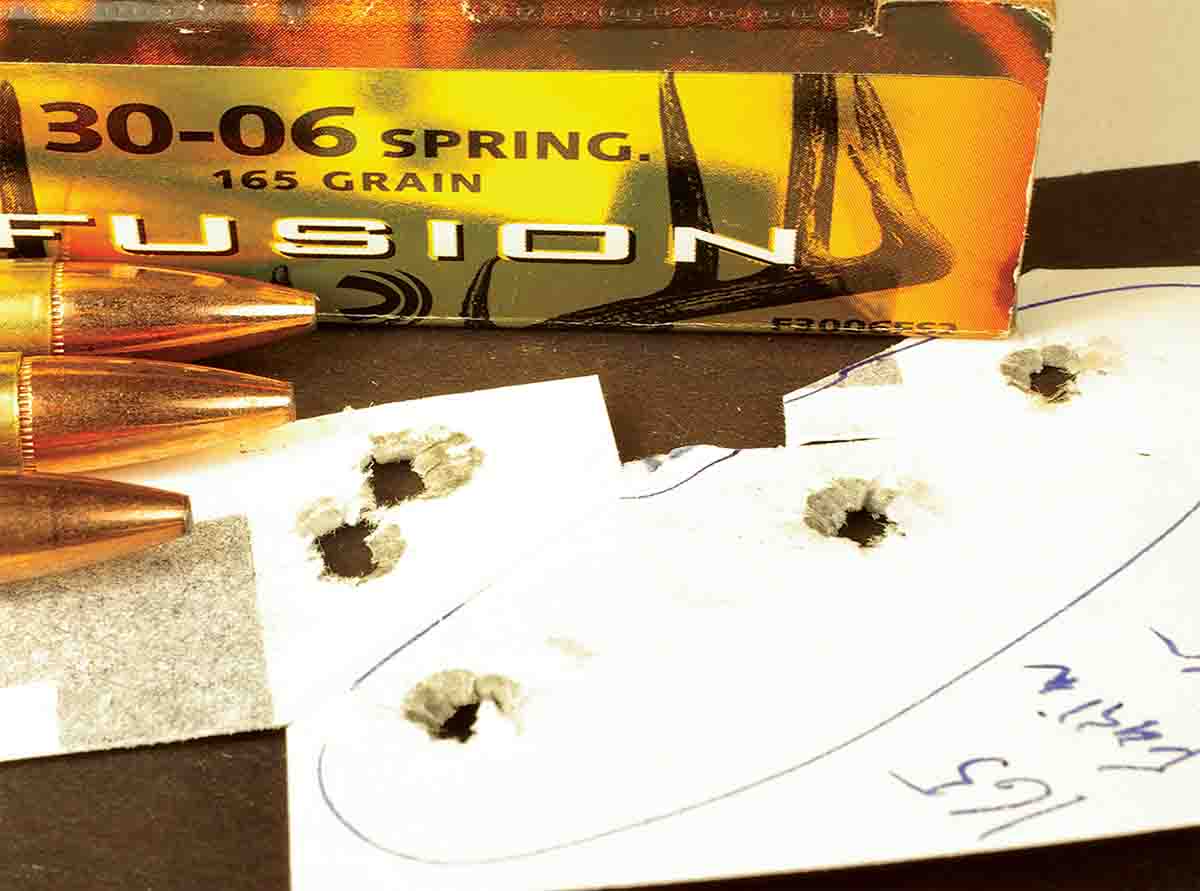

Foremost in my mind before shooting the Compass was T/C’s guarantee that the rifle can shoot one-inch, three-shot groups at 100 yards with premium ammunition. The first time at the range, groups were shot at 100 yards with six different .30-06 factory-loaded cartridges. The rifle tended to place two bullets close to each other, and a third bullet placed high or low by an inch or so with four of the loads. Remington Premiere 180-grain Core-Lokt Ultra Bonded loads printed an .80-inch group, so there was T/C’s promise of minute-of-angle accuracy.

The rifle shot adequately with most loads. Browning cartridges loaded with 155-grain BXR bullets and Federal Premium cartridges loaded with Sierra 165-grain Game- King bullets shot groups slightly smaller than 1.5 inches. Those groups were actually pretty good for a skinny barreled rifle, but the groups were not an inch, like the rifle’s accuracy guarantee promised. I shot the rifle and shot it some more, willing it to shoot better. Most three-shot groups still had a bothering vertical spread.

The rifle’s barrel was quite slender with a diameter of 1.10 inches at the front of the receiver and slimming to .63 inch near the muzzle behind the threaded cap. The barrel was free-floated; a thick piece of paper easily slid between the barrel and the stock’s barrel channel. There was a lot of flex to the forearm when I squeezed the barrel and tip of the forearm together with my thumb and index finger. Perhaps recoil force caused the forearm to bounce off the front rest, slap the underside of the barrel and send bullets in an erratic direction.

I placed the stock, at the front of the receiver, on the front rest when shooting off a bench in hopes of lessening that forearm flex, but that failed to tighten groups. Another solution to keep the barrel and stock separate would be to raise the barrel slightly by placing a small square of plastic, cut from a credit card, between the bottom of the receiver ring and the stock bedding. That would not work with the Compass, because its recoil lug would fail to seat in the slot in the bottom of the receiver ring.

In the 1941 book The Modern Gunsmith Vol. 1 by James Howe, Col. Townsend Whelen was quoted on how the Springfield Armory bedded Model 1903 rifles to obtain the highest degree of accuracy: “. . . the tip of the forearm should press upward against the bottom of the barrel a trifle harder than the remainder. That is, when the front guard screw is tightened the tip of the forearm should press up against the bottom of the barrel about five pounds’ pressure.”

Years ago Ruger M77s, Remington Model 700s and other rifles had a raised band crossway in the barrel channel near the tip of the forearm. That band placed some upward pressure on a barrel, like Whelen described, to dampen its vibration during firing. It improved accuracy of thin barrels especially well. Fitting that band is an extra manufacturing step that is omitted today on budget-priced rifles. Most of these rifles have a synthetic stock with an oversized barrel channel that allows free floating a barrel. That arrangement usually works well, until it doesn’t.

I keep an outdated credit card at hand that serves as a temporary pressure point on a barrel. The card was shoved in the front end of the Compass’ barrel channel underneath the barrel. The gap between the two, and the flex of the forearm, required folding the card in half to make it thick enough to wedge it in tightly. With moderate optimism, the Compass was shot at targets at 100 yards. First up were Federal Premium cartridges loaded with 180-grain Tipped Trophy Bonded bullets that shot a 1.38-inch group, much tighter than the original 2.50-inch group. Pressure on the barrel from the card also helped tighten a group shot with Winchester Supreme cartridges loaded with 168-grain Ballistic Silvertip bullets. Federal cartridges loaded with 165-grain Fusion and Sierra GameKing bullets and Winchester Supreme 180- grain E-Tip loads shot groups under an inch. So there were three loads that fulfilled Thompson/Center Compass’s accuracy guarantee.

Perhaps the card kept the forearm from slapping the barrel, or it dampened barrel vibration. Maybe it was both. Whichever, it worked. If the rifle was mine, I would replace the unsightly card with a band of bedding compound across the barrel channel a couple of inches behind the forearm tip. The forearm is hollow, except for the X-shaped lattice that adds stiffness to it and the pillar for the sling swivel stud. So quite a bit of bedding compound would be required to build up a foundation for a band to support the barrel.

Handloaded Berger 185-grain VLD Hunting bullets were shot through the rifle during a couple of evenings. The rifle’s slim and rounded forearm fit the palm of my hand, and the flute on the nose of the comb positioned the pad of my index finger exactly on the trigger. The safety was easy to reach and flip through its positions with my thumb while my hand remained around the grip. My aim wavered some when shooting offhand. Still, the bullets cracked rocks on a hillside. With the rifle supported on a tripod, groups mostly stayed on either side of 3 inches at 100 yards.