Light Gunsmithing

Optic-to-Base Attaching Screws

column By: Gil Sengel | March, 21

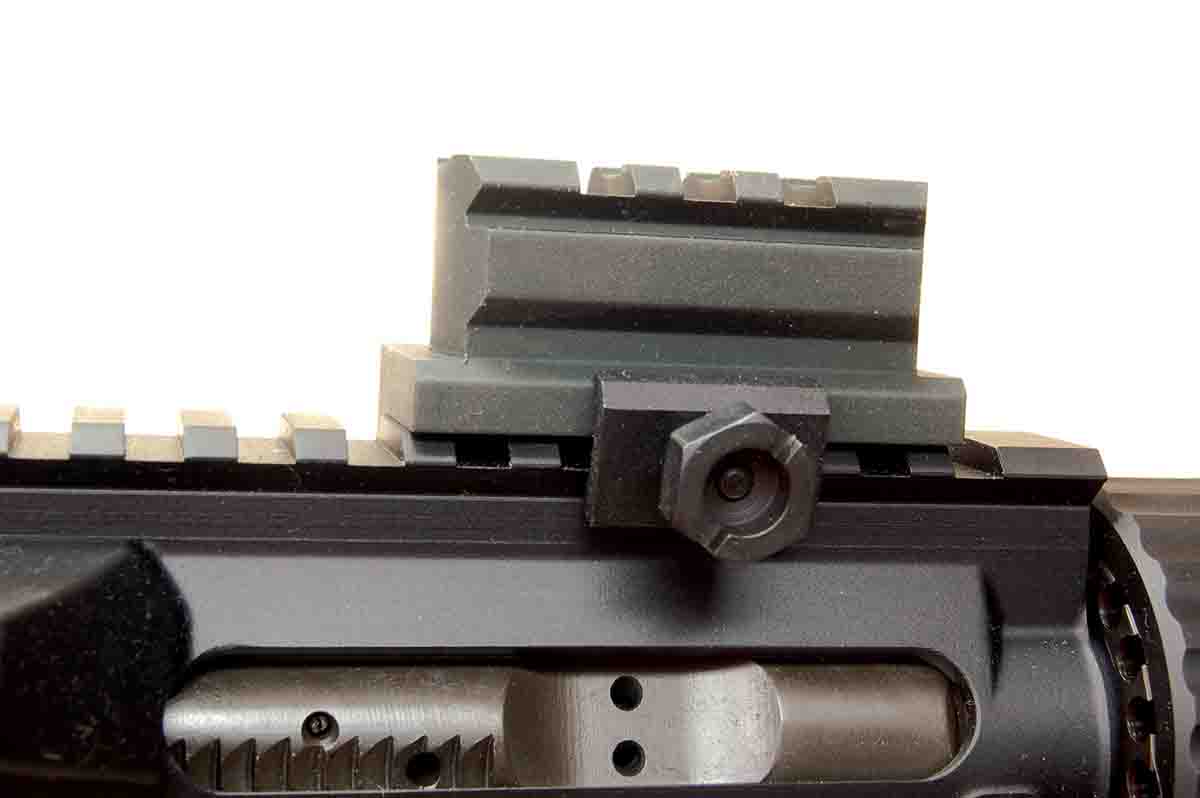

Then there is the application of today’s optical sights. Red dot sights in their several variations are replacing conventional open iron sights. None attach using standard scope rings and bases, but instead clamp to a section of Picatinny rail screwed to the receiver/barrel. The rail may be as long as the receiver, extend out on the barrel a few inches or even stretch to the muzzle!

With their unlimited eye relief, red dot sights can be attached anywhere on the rail. So can various crude open sights. Of course, standard scopes with proper rings also fit Picatinny rails, as do long eye relief pistol scopes and scout scopes. All this stuff is quickly removable, replaceable and switchable on one rifle or among several. No longer is the optic-to-base attaching screw tightened once and ignored for years. Sights can be changed a couple of times a year or a couple of times a day, depending upon use or hunting conditions. Optic-to-base attaching screws received considerable wear and abuse from overtightening.

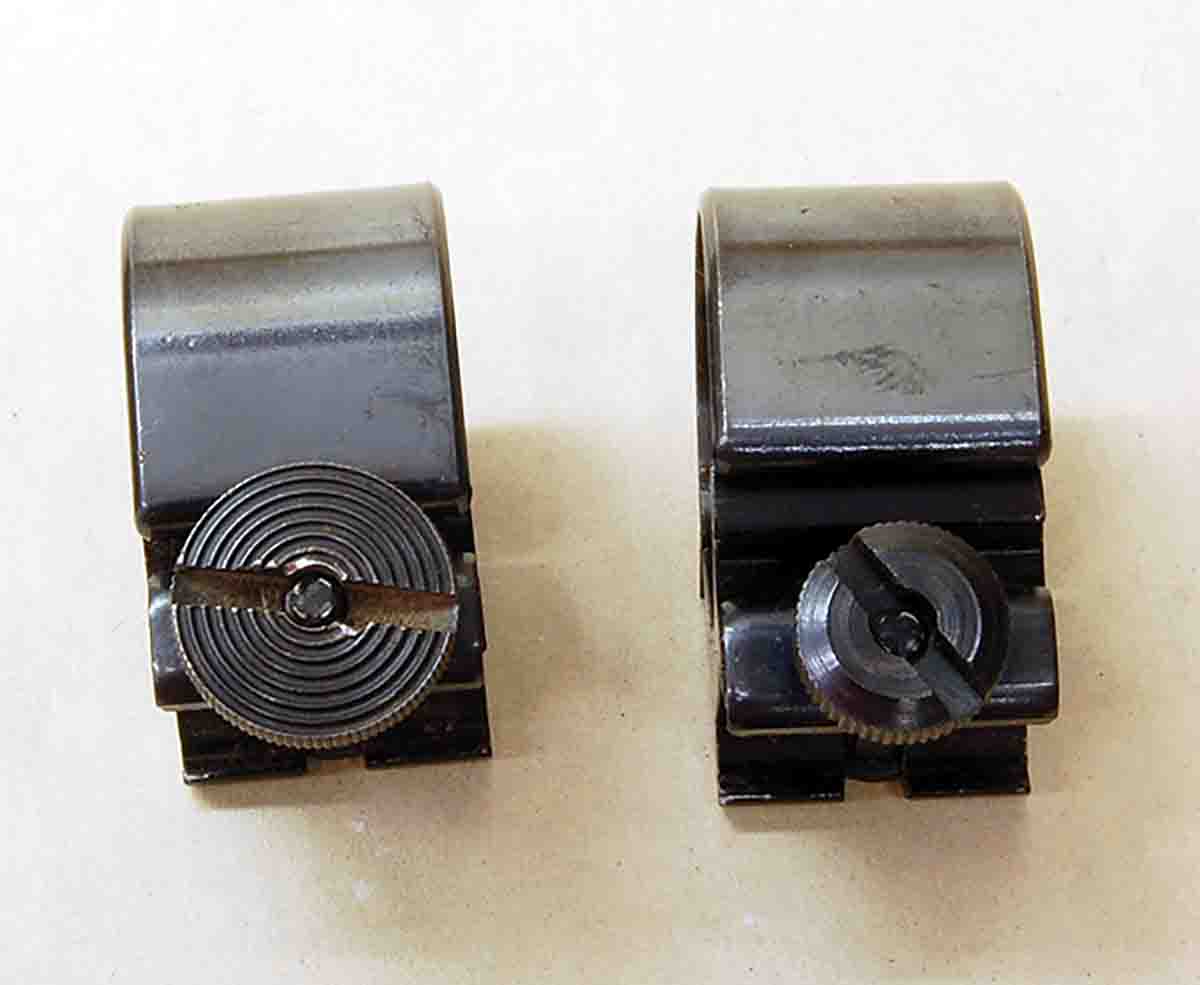

The Picatinny rail is essentially just an elongated Weaver Detachable Top Mount base, but with equally spaced transverse slots instead of just one or two. Since Weaver bases have been available for at least 70 years, there are a lot of Weaver scope rings in circulation. Much switching (accompanied by overtightening) leads to wear or bending of the attaching screw, nut or clamping plate they pass through or thread into. This is totally unnecessary.

If the optic frame or rings connecting it to the Picatinny base are first pushed forward so the attaching screw contacts the transverse base slot, then even if only moderately tightened (20/25 inch-pounds) it is pulled down against the angled surface of the rail. There can be no looseness in the system. It’s impossible. The only fault can be shearing of the 6x48 tpi screws holding the rail to the rifle’s receiver.

Unfortunately, the usual process consists of slapping the optic onto the rail, moving it until the attaching screw falls into a slot, then bearing down on the attaching screw with one of those annoying magnetic tip screwdrivers holding whatever tip was last used. Since these screws have larger diameter heads and wider slots than other gun screws, the result is damaged slots and overtightening. This can be prevented.

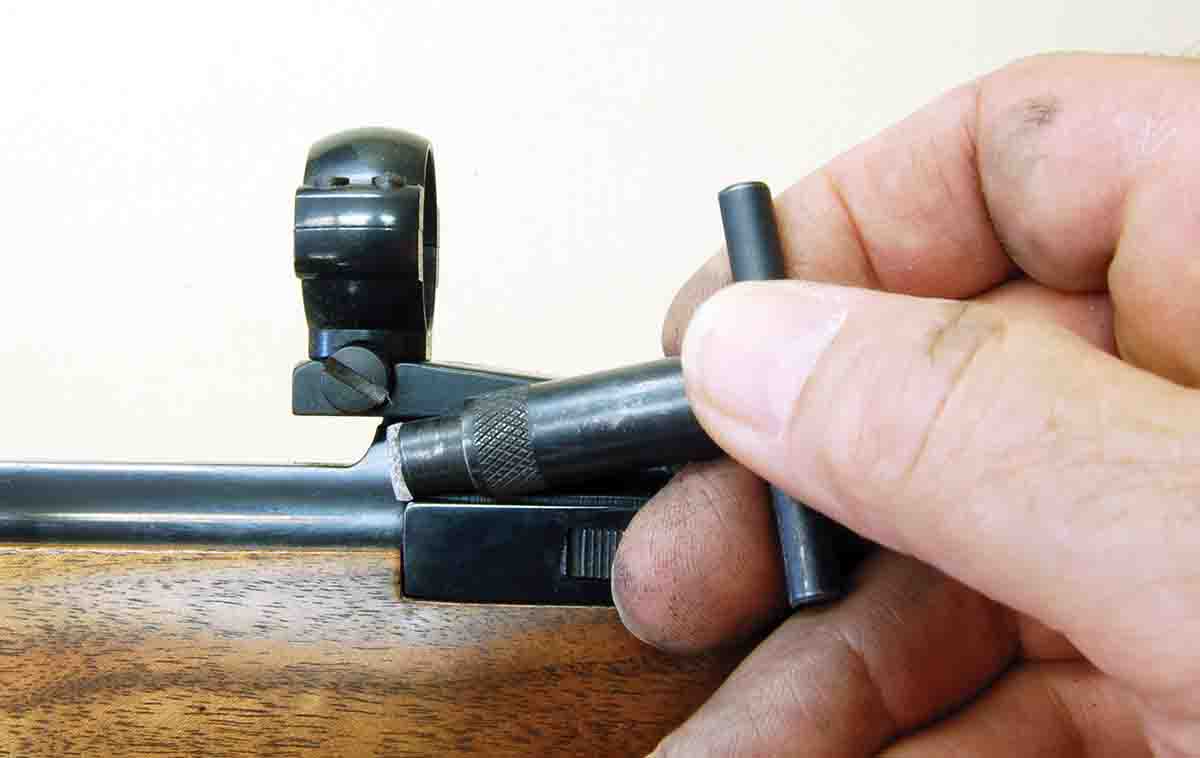

The wide-nosed butterfly fits old Weaver rings and many other makes. The wrench with the narrower nose fits newer Weaver rings and old side mounts used on countless .22 rimfires. Screw slot damage and overtightening are now prevented because it’s impossible to apply enough force with just the fingers for most folks to damage anything. Make several and scatter them around so one is always handy!

Another photo shows a short, round-bodied screwdriver. The T-handle is made from a 2-inch long, .25-inch diameter roll pin. Its only use is Redfield all-steel scope mounts, once very popular for hard-kicking rifles. The screwdriver end is easily filed on a piece of half-inch round stock. It makes much more torque possible than the butterflies, but it’s necessary for the Redfield attaching screws. Plus, the short length prevents it from slipping out of the slot, which is so common when using a long screwdriver.

Getting back to modern Picatinny rails, it is logical that as rifles look more and more like garden tools, the slotted head screws would give way to hex heads. The one shown in the riser block on an AR receiver is a half-inch (or maybe 13 milli-things, which is the same). First impulse here is to grab a ratchet wrench, but that will twist off the head or damage the locking plate before much resistance is felt. The proper tool is a nut driver. This is a screwdriver shank and handle with a hex socket forged on the end. It can’t slip off the screw head and is vastly superior to a slot head and screwdriver. Nut drivers are used in electrical work and are available wherever tools are sold.

Lastly, a situation should be mentioned that doesn’t directly involve the optic/Picatinny attaching screw. This is damage (impact, dents, deep scratches) to long rails in areas the currently mounted optic base doesn’t cover. When that optic is switched to one that fastens to another part of the rail and covers the raised metal around the dent, proper attachment is impossible.