Light Gunsmithing

Maintaining Early Winchester Model 52s

column By: Gil Sengel | March, 23

The response of many rifle folk to the above title will be something like, “Winchester Model what?” This is not surprising. The Model 52 was designed, built and continually improved to be a bullseye .22 rimfire target rifle only. It was full-size, heavy and expensive. Anyone not involved in small-bore target shooting would never see one.

The rifle history begins in November 1917, when Winchester decided to drop the Model 1885 single shot and replace the rimfire target version with a bolt-action repeater. There was no hurry until December 1918 when Winchester learned that the army was interested in such a rifle. Still not in much of a hurry until January 1919, when Savage Arms Company revealed it not only had such a rifle, but was about to submit it for government approval. Now there was a hurry!

Savage was to have its rifle shot at the National Matches at Caldwell, New Jersey, in August 1919. Somehow, Winchester sent at least five handmade rifles to Caldwell where they performed splendidly, winning top spot in several events. Competitors liked it because it was made as a target rifle with a 28-inch heavy barrel and adult-sized stock (mine weighs near 9 pounds).

The Savage rifle didn’t fare well. It shaved lead from bullets when feeding from the magazine; some rounds didn’t feed at all. Also, its shorter and lighter barrel gave it the feel of a hunting rifle. Winchester had nothing to worry about.

After some minor changes, the rifle was designated Model 52 and officially introduced in April 1920. This makes the first variation, with its slow-lock, cock-on-closing action, just over 100 years old. Some 16,000 were made until about 1930. The one shown here was made in 1923.

Target matches take place regardless of the weather. It is a safe bet these rifles have been out in the rain or cold and subject to condensation with little more than a light wiping off. Disassembly, thorough cleaning, removal of any rust and lubricating will keep them shooting for another 100 years.

There are four areas of concern for any Model 52 including general rusting in concealed areas such as the bolt, magazine release and trigger. Light rust is removed as disassembly proceeds using a few drops of solvent and No. 0000 steel wool. Pitting generally occurs at the barrel/stock junction and hidden edges of the trigger guard. All that can be done is to soak it in something like WD-40 for a few days to be sure the rust is dead, then rub lightly with a patch soaked in RIG gun grease.

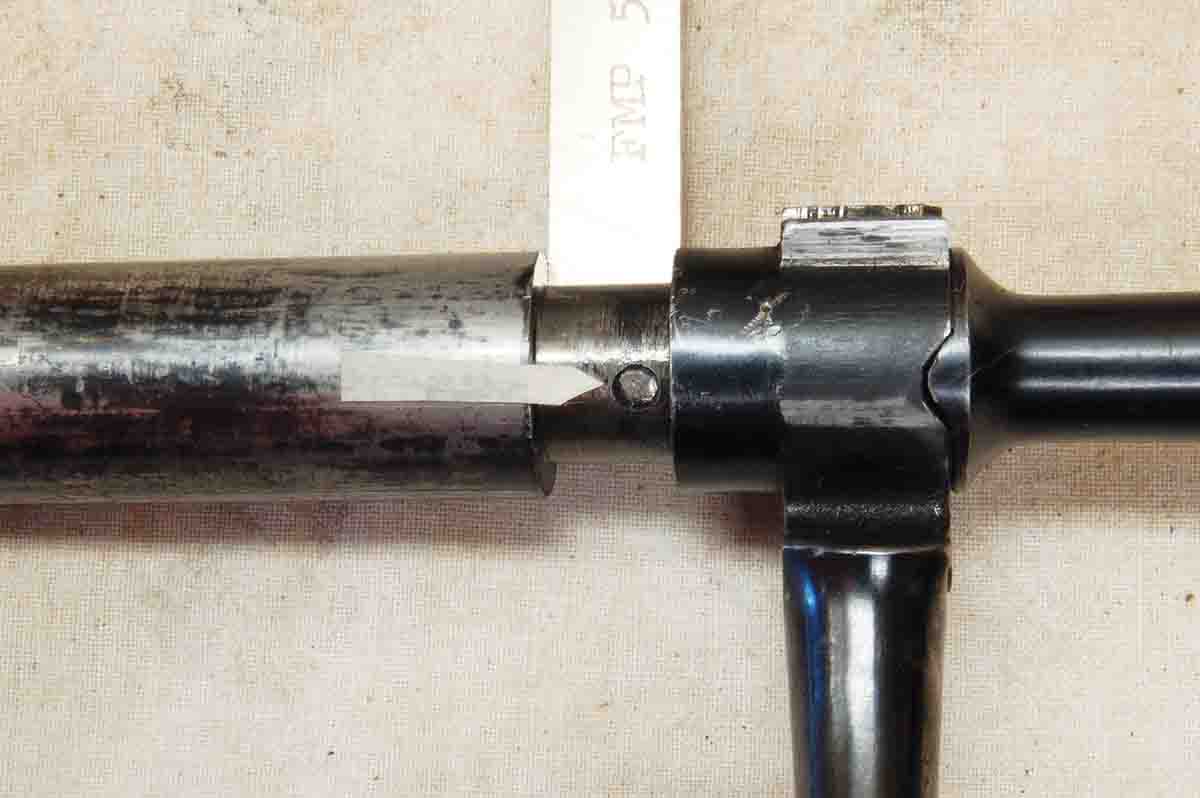

Disassembly of the bolt is begun by driving out the one visible pin at the base of the bolt handle to slide backward, exposing another pin. The accompanying photos show this. If no rust is found, there is no need to remove the second pin as it is under the mainspring pressure and difficult to reinstall. A couple of drops of oil are necessary in this area before reassembly because it has probably not been lubed since the gun was built.

Next is the magazine release plunger, a short piece of steel rod working in a hole through the side of the stock. It is retained by a spring-loaded magazine catch attached to the receiver. If the plunger falls out when the barreled action is removed from the stock, all is well! If it doesn’t, check for rust or what appears to be stock finish in the hold. A Model 52 will never lose a magazine if the plunger works freely.

Finally, there is the trigger. It is a simple two-stage military design with a short first stage. The pull on the rifle shown is 1 pound, 12 ounces. Someone has changed the sear spring. There are no adjustments. A drop of oil on the sear pin and a bit of grease on the sear surface is all that is needed.

Despite the overwhelming acceptance of the original of the Model 52, a second variation appeared in April 1930. It had a new stock designed by well-known competitor A.F. Laudensack. Its larger dimensions brought the gun’s weight to more than 9 pounds. Alteration to the bolt provided cock-on-opening and firing-pin travel was greatly reduced. Winchester called it Speed Lock. A new trigger was included as well. All parts are out in the open so cleaning is easy. It also has a tiny sear engagement screw visible from the rear of the action with the bolt removed. The pull weight of the rifle shown is exactly 3 pounds. For anyone interested, cut-away drawings and technical explanations of each of the Model 52 triggers is covered in Rifle No. 62 (March-April 1979).

Everything said about maintaining the first variation Model 52 applies to the second except for the bolt. It disassembles the same way, but this is not necessary since firing pin movement is so small. Just put two drops of oil in the bolt as shown in the photo. Then, stand it on its nose for a couple of hours. The oil will run down into the bolt and lube it perfectly.

About 1935, a third variation Model 52 appeared. The only change was in the safety, which doesn’t concern us here. However, the letter “A” was added as a suffix to the serial number and changed to the next succeeding letter with each mechanical addition to the rifle. Thus, this gun is known as the Model 52A.

The Model 52A didn’t last long. A Model 52B began production in 1937. It had the safety moved to the right-hand side of the stock, which necessitated minor changes to the speed lock. Then, there was a new trigger. Unfortunately, almost as soon as the rifle was released, complaints began regarding the trigger.

At first, it was annoying trigger movement at release. It can be seen how this might occur given grossly improper adjustment of the trigger. Then there were complaints of “vibrations during trigger let-off.” This was/is baffling. Engineers could not duplicate it, so they couldn’t fix the problem. Eventually, they gave up. The Model 52B trigger remained unchanged until the Model 52C came along after World War II. It definitely cost the company sales.