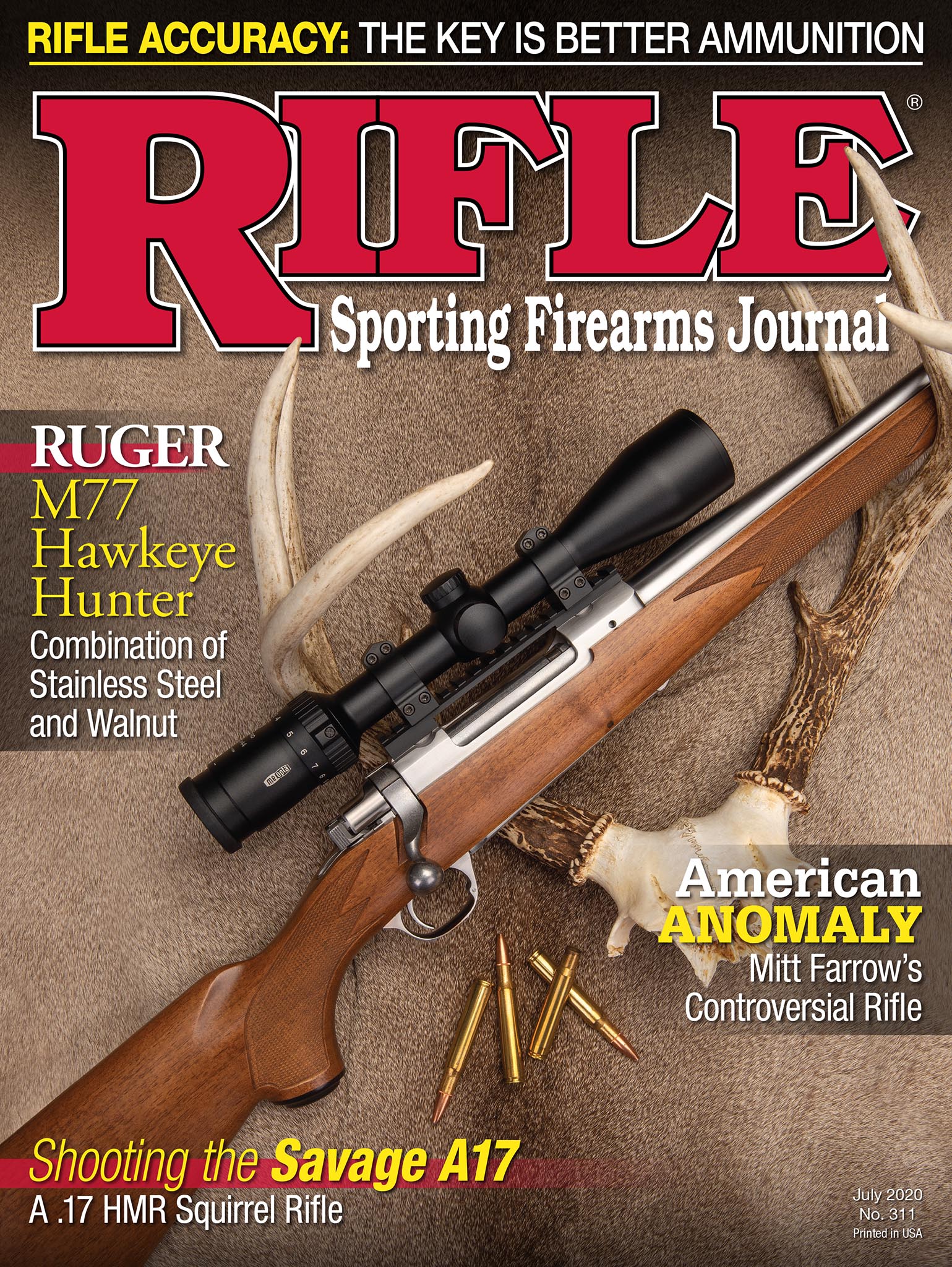

Ruger M77 Hawkeye Hunter

A Combination of STainless Steel and Walnut

feature By: John Haviland | July, 20

The Hawkeye Hunter is the newest model. The Hunter is available with a short action in 6.5 Creedmoor, 6.5 PRC and .308 Winchester. A standard length action is chambered in .30-06 or .300 Winchester Magnum.

The Hunter’s stock is made of straight-grain American walnut with a straight comb and checkering on a slender grip and forearm contrasting with bright stainless steel metal right down to the trigger guard and hinged floorplate.

The Hunter I’ve shot over the last several months was chambered in .30-06. It accurately shot a variety of factory and handloaded cartridges. No matter if its barrel was clean or sat dirty for a week, its first shot of the day landed in the same place as did subsequent bullets.

The Hawkeye’s receiver is on the heavy and large size with a flat bottom and 1.40-inch diameter receiver ring to house the external extractor, which requires a deep right raceway, two flat side rails and a closed bridge. The breach end of the barrel is bedded against the bottom of the stock’s barrel channel for about 1.75 inches. The remainder of the barrel is free-floated.

A portion of the bottom of the bolt face rim is milled flush with the bolt face so a cartridge rim slips under the extractor as it’s stripped the last way out of the magazine. This controls the cartridge from the moment its stripped from the magazine and it, or a fired case, is extracted and a blade ejects it. A slow pull on the bolt knocks a case free of the extractor so it remains on top of the follower or falls out of the ejection port. A hard pull throws it well clear of the rifle.

To keep the bolt running smoothly, the left locking lug rides in a raceway inside the receiver and a guide rib on the middle of bolt rides on top of the left cartridge support rail. The bolt cycled somewhat roughly because the raceway and rail were fairly rough as the rifle came from its factory box. Bolt travel was smoothed up considerably after the bolt had been cycled several hundred times.

A receiver’s ability to absorb recoil depends on the size and position of its recoil lug. The Ruger’s recoil lug is relatively shallow and lies under the receiver ring. The lug transfers recoil energy to an inch-thick block of wood between the recoil lug mortise and the opening for the magazine. The .300 Winchester Magnum is the largest cartridge chambered in the Hawkeye Hunter, and its recoil is handled well by this arrangement. Hawkeye African models chambered in .375 and .416 Ruger, though, are made with crossbolts in their stocks to withstand recoil.

The Hawkeye’s flat bottom receiver beds to the stock along nearly two square inches beneath the receiver ring. Tightening the front guard screw pulls the recoil lug down and to the rear into the stock mortise, where it fits flat against the stock. The instruction manual for the Hawkeye states this screw should be tightened to 95 inch-pounds. Vertical guard screws at the tang and behind the magazine well should be tightened to 45 to 60 inch-pounds. Old Ruger M77 rifles shot more accurately with the middle guard screw only gently tightened because fastening the screw too tightly bowed the receiver and caused groups to widen.

These days much of a rifle’s accuracy is attributed to complex bedding of the receiver to synthetic stocks manufactured of materials as rigid as railroad rail. There are also aluminum frames to cradle the whole receiver, or at a minimum, pillars to hold receiver screws in inflexible contact with a receiver, glass bedding of a stock’s entire inletting or at least around the recoil lug. The Hunter’s receiver-to-stock bedding, though, is only steel against plain wood.

The Hunter comes with a 20 minute of angle Picatinny rail fastened to the top of the receiver with four 8-40 screws. Rails are all the fashion because nearly any clamp on mount attaches to them. But the rail covers the slots machined into the top of the receiver to mount Ruger’s traditional integral scope mounts, one of the best features of Ruger M77 rifles for 50 years. The rail sits up fairly high on the receiver and I used low clamp on scope rings to mount a Meopta Meopro 3.5-10x 44mm scope. Even with the low rings, the Meopta’s objective bell sat high above the barrel. The addition of the scope and mounts brought the 7-pound, 8-ounce basic weight of the Hunter up to an even 9 pounds.

The Hawkeye Hunter’s accuracy was excellent for a pure hunting rifle. The average group size was 1.07 inches at 100 yards for two, three-shot groups with five factory loads. Adding the two handloads, average group size shrank to .913 inch.

The Hunter’s straight-grain American walnut is old-school classic with a straight comb, somewhat slender grip and 10.5-inch long forearm. Point-pattern checkering panels on the sides of the grip, wrap-around checkering on the forearm and flutes on the nose of the comb contribute to the stock’s good looks. A half-inch thick red recoil pad, hard as a tractor tire, caps the butt.

The comb could be somewhat higher and still allow for removing the bolt. That would have been nice, as the Meopta scope sat high enough on the rifle that I had to nearly put my jaw on top of the comb to align my eye behind the scope. The addition of a sandbag alongside the comb helped support my cheek on the comb while shooting off a bench with the rifle supported on front and rear rests.

From that support, I shot Berger 150-grain FB Target bullets handloaded with Shooters World Precision Rifle and Match Rifle powders. The only extra preparation for the handloads was seating the bullets .004 inch short of contacting the rifling in the Hunter’s barrel.

The Precision Rifle handload grouped three of the Berger bullets in .69 inch and three more in .87 inch at 100 yards. Shifting to a target at 300 yards, three bullets formed a 1.31-inch group, and three more bullets produced a 1.43-inch group. In minutes of angle, those 300-yard groups were tighter than the 100-yard groups. It’s been quite some time since I’ve shot tighter groups at 300 yards with any hunting rifle.

The Match Rifle powder and Berger bullet handload provided three-shot groups measuring 1.02 inches and .76 inch at 100 yards. I clamped a Harris bipod to the Hunter’s front swivel stud and wiggled into a comfortable prone position behind the rifle to shoot that handload at 300 yards. The scope’s reticle wandered some then settled on a target. The first three bullets landed in a 3.71-inch circle and the following three in 3.04 inches.

All the credit for that accuracy goes to Ruger for refining its M77 hunting rifle for 52 years, with the Hawkeye Hunter the epitome of that evolution. Its barrel never wavered, providing great accuracy from a cold first shot through constant shooting. The controlled-round feed action never bobbled a cartridge or fired case and its three-position wing safety provided the utmost in safety. The Hunter’s slender walnut stock gathers it all into a good-looking hunting rifle.

.jpg)