Spotting Scope

Ballistics and Statistics

column By: Dave Scovill | July, 18

Statistics: the branch of mathematics that deals with the collection, organization and interpolation of numerical data. Statistics is especially useful in drawing conclusions about a set of data from a sample of the data. (See mean, median, mode, normal distribution curve, sample, standard deviation and statistical significance.) Typical problem: estimating true value of parameters from a sample of data.

The paragraph above is a brief Internet summary from dictionary.com, but is fairly close to the orientation sheet passed around the classroom on the first day of a statistics course during my junior year at the University of Oregon. It was pretty droll stuff, but a required course for my major in architectural design and engineering. Oddly enough, it became one of the most interesting aspects of my writing 40 years later.

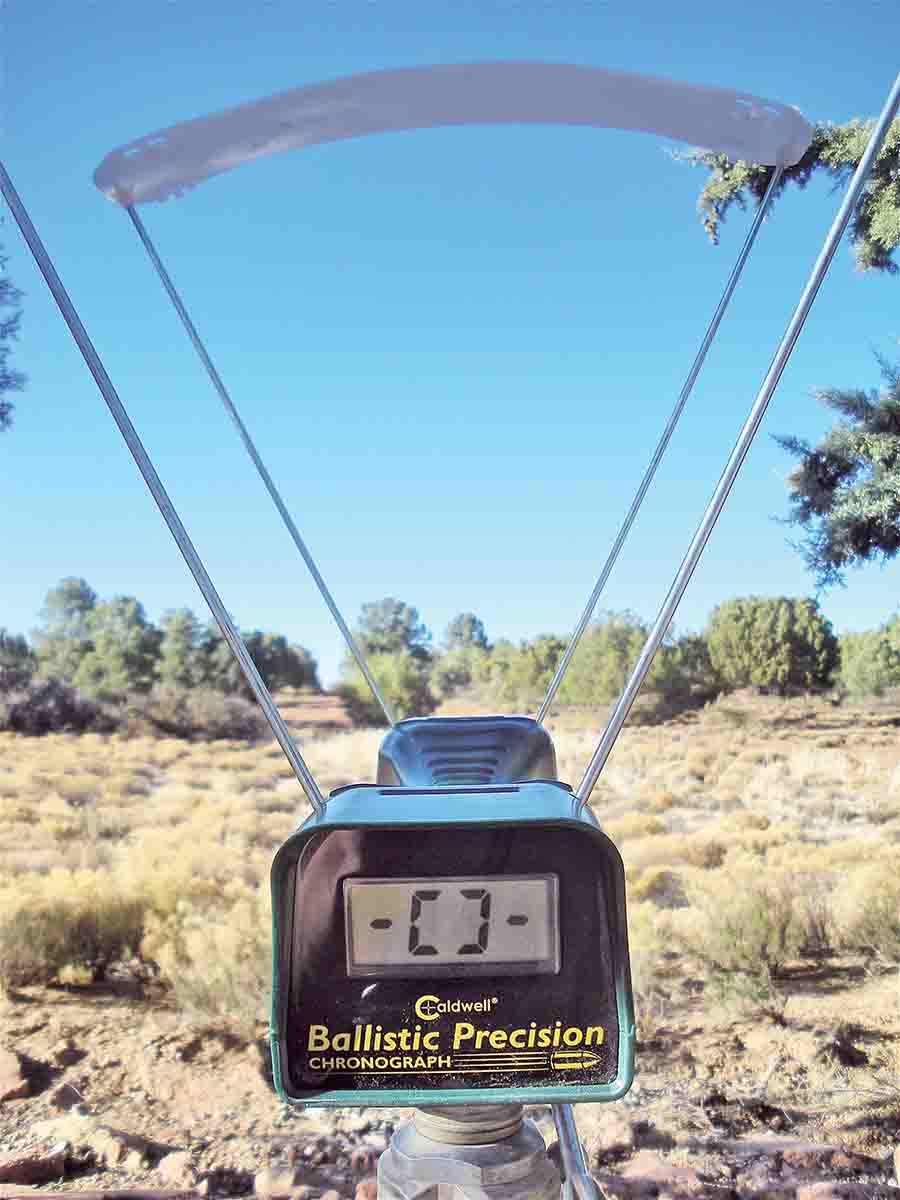

It all came home when I purchased a Custom Chronograph with printed screens back in the late 1970s. The system was fairly straight forward: Mount a screen in each set of two clips mounted at either end of a 2-foot piece of plywood. The clips were wired to a unit that read the velocity of the bullet, BB or arrow that was fired through both screens, starting and stopping an electric circuit that was converted to velocity in feet per second. Screens were replaced after each shot, and were sold in packs of 100 to 1,000.

Sometime after purchasing the Custom Chronograph, Dr. Ken Oehler came out with the new Oehler Model 33 Chronograph that not only determined velocity but also calculated Standard Deviation (SD) for each string of shots. Right off, writers around the industry began to assert that SD could be used to predict accuracy. That is, lower SD numbers implied better accuracy potential than higher SD numbers, which also implied a great deal of gullibility on behalf of anyone who might believe that – simply because there was no standard method to apply SD by the number of shots in each set or group, or the number of sets required to validate SD.

There were also other factors to consider other than velocity, such as variations in bullet weight/diameter, charge weight and case weight/volume, that might collectively, or individually, affect accuracy, which is/was not to ignore the simple fact that some rifles don’t shoot some bullets well.

At that time the only realistic means to calculate SD using velocity data collected by the Custom Chronograph was to purchase a Texas Instruments scientific calculator and use all the data collected in notebooks for respective cartridges over the years. That’s when the bottom fell out of the notion that SD had any remote connection to accuracy. The most obvious error in assuming accuracy and SD are related comes up when one understands that as we shoot groups with three, five or 10 shots, SD naturally becomes smaller as the number of shots increase. Of course, the biggest fallacy in the assumed correlation between SD and accuracy was that it left out the shooter, me. So to get a second opinion, a call was placed to Dave Andrews, the ballistician at Speer, to determine how SD might be used in production of bullets.

Several years after that conversation with Dave Andrews and consulting with a few other engineers at various bullet manufacturers, David Miller, (David Miller Rifle Co., 3131 East Greenlee Rd., Tucson, AZ 85716) who, along with stock maker Curt Crum, is widely recognized for building some of the finest custom rifles in the country, mentioned the Juenke machine. The name was news to me, but Dave went on to say it was developed by Vern Juenke, a well-known benchrest shooter, to measure the internal and external concentricity of bullets. Dave found that by rotating the bullet on the machine it measured variations in internal dimensions and virtually eliminated the occasional bullet that might show wide variations. In other words, the needle wobbled well beyond acceptable parameters.

In the worst case, up to half of a box of 100 match-grade bullets would be eliminated for accuracy work, which resulted in the absence of flyers that would routinely double or triple group size out to 600 yards. This, in spite of the fact that all external measurements, weight, etc., were perfect. The net result is that when you buy a David Miller rifle, the ammunition that comes with the rifle will shoot well inside minute of angle at 600 yards . . . if you can.

Not long after learning of the Juenke machine, I bought one and used it extensively to evaluate nearly every bullet brand and design on hand at the time. There appeared to be no external signs that might reveal why some bullets failed to pass muster, but it was pretty obvious that no one could tell the difference between good, marginal or bad bullets just by looking and/or measuring and weighing them. Neither was there any explanation for why any given box of bullets from whatever brand might contain several or few culls.

After spending several months with the Juenke machine it was forwarded to John Barsness for further evaluation. Ultimately, John decided that some other external factor, such as dropping boxes, or crates of bullets on a loading dock might reveal the source of the spurious bullet quality that shows up on the machine. Either way, judging from the high polish and colorful tips on most bullets sold around the country nowadays,

it is intriguing to know the old Juenke machine represents the only known (to me) method for evaluating bullets – inside and out. Which is not to ignore a few folks on the Internet who would prefer to dismiss the concept out of hand without first giving it a fair shake.

For anyone that might be interested in purchasing a Juenke machine, an outfit called Bullet Inspector (BulletInspector.com) on the Internet sells kits, but emphatically cautions that you should have superior knowledge of electronics if you buy one, or you will never be able to assemble it. A schematic on the website shows the layout for the kit. Either way the kit is pricey and there is a long wait, apparently, if you want one assembled.

Absent a Juenke bullet comparitor, any explanation for unexplained flyers is pretty much up to speculation as to whether they might be caused by the shooter, variations in primer ignition, wind drift, the barrel doesn’t like the bullet of interest, the bullet, or all of the above, or some other spurious factor like loose scope mounts, scope parallax, etc. – or take your best guess.

In an effort several years ago to come up with some reasonable way to validate SD without shooting up an entire box of bullets, which seems a bit foolhardy, it was decided to shoot two sets of five shots, calculate SD for each set, then use the total of 10 in a third set, as a test to validate SD. It seemed to make sense and kept the number of test shots to a minimum. Whether or not that passes the “smell” test with professional statisticians is “who cares.” At least it is reasonably practical and only requires 10 bullets from a box of 100, or more recently, 50-count packaging.

As a writer, or editor, it occurred to me that use of the Juenke machine was a non-starter, mostly because it eliminates any given bullet from a box that consumers purchase off the shelf. That skews accuracy tests, and may unfairly suggest any given rifle is capable of a degree of accuracy that it can not be expected to produce with off-the-shelf bullets and handloading components. In other words, flyers are flyers, and while experienced shooters may be able to trace the cause, most of us are left to hope, at least, they are not due to lousy shooting skill in general, or just a bad day at the bench.

The bottom line with all the above is that a handloader can match prep brass, weigh bullets, powder charges and primers, and double-check everything, not to ignore cleaning the rifle barrel, and it’s all for naught if you drank too much coffee before sitting down at the bench, where SD has nothing to do with a shaky trigger finger.