Walnut Hill

Definitions of Handling Characteristics

column By: Terry Wieland | March, 18

Back in the 1950s, a linguistics professor in England ignited a minor firestorm with an article about differences in language between the upper classes and the aspiring middle class in what was then, still, a very class-conscious society. He found that the upper and lower classes were likely to use the same terminology – simple, direct words – while the social climbers of the middle class, seeking to appear refined, would use either elaborate words or euphemisms.

An example is “loo,” which the middle classes replace with “toilet.” In America, the comparable difference would be “can” and “commode.” The professor coined the terms “U” (for upper) and “non-U” to denote which was which. Soon, people of all classes were defining everything around as U and non-U.

G.T. Garwood was a prominent English shotgun writer of that period, who went by the nom de plume of Gough Thomas. An engineer by profession, he was looking for a way to define handling characteristics in firearms of all kinds, and in a clever play on words coined the word “eumatic,” which could be shortened to “eu” and “non-eu.”

On the surface, it would seem to be virtually identical to the study of ergonomics, but there was more to it than that. The term “ergonomic,” which is now in common use, was coined by a Polish scientist in 1857; a century later, in 1949, a group of English scientists held a meeting at the Admiralty and set up the Ergonomics Society, a group dedicated to expanding concern for ergonomics in everyday items. Put more simply (less non-U, perhaps), ergonomics could be defined as natural usability.

Eumatics was all of that, but included a psychological aspect as well – the element of intuitive use. A eumatic mechanism is not only one that is easy and convenient to use, but it also incorporates a natural motion that quickly lends itself to instinctive operation, with no conscious thought.

There are all kinds of examples, good and bad, in the long history of firearms. Gough Thomas himself pointed to the pump-action shotgun as a stellar example of a eumatic mechanism – so much so that it almost operates itself. In the rifle world, the lever action is very similar, and this accounts for its continued popularity in a world where it can’t match newer mechanisms for power and accuracy.

One quality in a mechanism that Gough Thomas singled out as definitively non-eu was the type of mechanism that stubbornly resists operation, then suddenly breaks free and races either forward or backward, causing the operator to savage his knuckles on some protruding edge. Most straight-pull rifles are like that to some degree, as are the cocking pieces of various military semiautomatics.

There are many gun-related mechanisms and designs that are still used regularly after a century or more. Their longevity can usually be credited to their eumatic qualities. To look at it the other way, no non-eu design that I can think of has lasted very long unless it displayed an overwhelming advantage in other areas.

The common turn-bolt action is a prime example. It is even more non-eu than the straight pull, but it more than makes up for it in accuracy, durability, strength and reliability. The very best gunmakers, both factory and custom, have gone out of their way to minimize non-eu qualities by making their bolt actions smooth and slick to operate.

The external hammer found on the Winchester Model 94 is very eumatic, which fits well with its lever action. Like the pump, the lever is a natural motion with the hand moving forward (and taking the lever with it) as the rifle recoils.

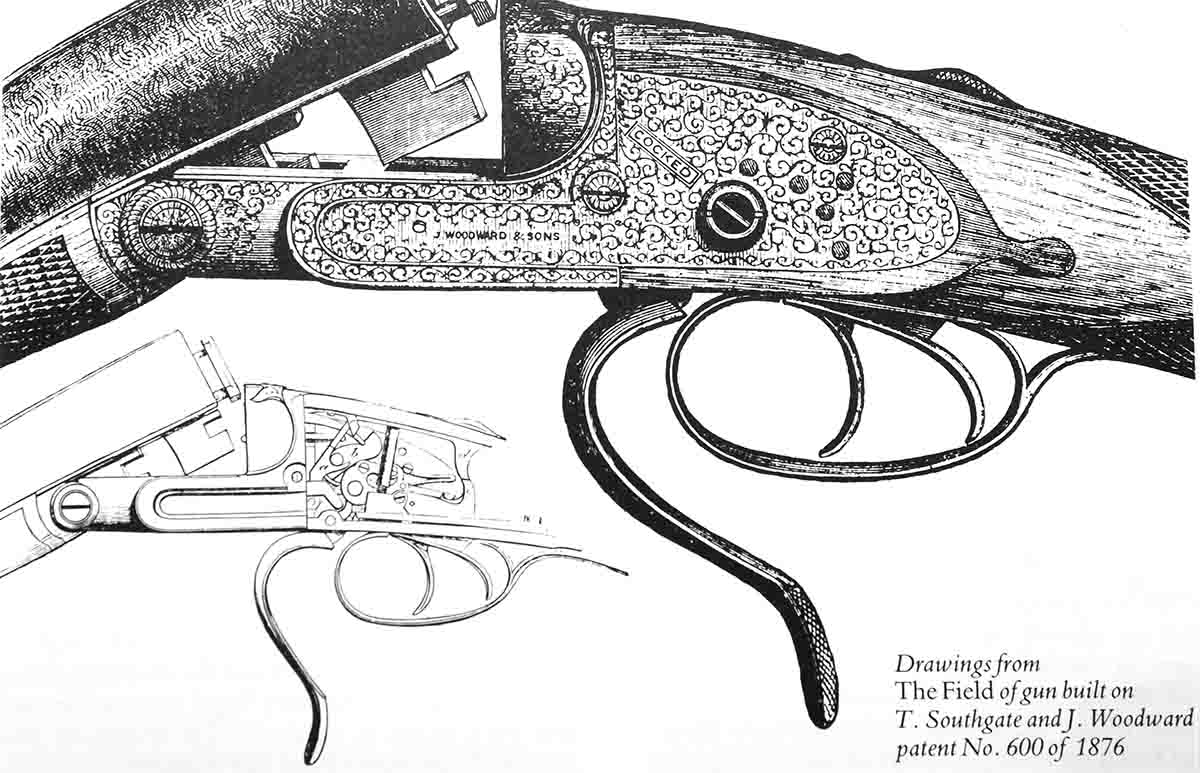

I found out just how eumatic the lever is completely by accident. Several English gunmakers, notably James Woodward, used a snap underlever on both double rifles and shotguns. When I shoot one of these, I adapt to the underlever very quickly. When I then return to the more common Scott top-lever, I find myself automatically reaching for the underlever for days afterward. This is not to say that the combination of Purdey underlugs and the Scott lever and spindle is not eumatic, because it is. It gained ascendancy because it combined a high degree of eumatic operation with elegance and ease of manufacture, and became the standard to this day while the snap underlever disappeared.

The tang safety found on doubles of all kinds is a very eumatic design that has been adapted to various rifles as well as shotguns. It was used in the late years of production on the Savage 99, the early Ruger Model 77 bolt action and in some models of the Mannlicher-Schönauer, among others. I don’t like it on a rifle at all, especially a bolt acton. To me, the only safety that makes sense either eumatically or functionally is the three-position wing. This accomplishes exactly the same things as the original over-the-top wing found on the military Mauser ’98, but it does so in a way that is easier to use – as well as accommodating a low-mounted scope.

Ruger’s move from the tang safety to the three-position wing on its Model 77 was one of that company’s best decisions, and it moved the Model 77 into the top class of bolt-action rifles.

Detachable scope mounts cover the entire range of eu and non-eu, with some of them achieving a pinnacle of decidedly un-ergonomic operation that would be hard to match if you set out to do it deliberately. The Pachmayr “Lo-Swing” mount, which is no longer made but was sold in such numbers that they are commonly found on used rifles, is a fine example of a mediocre solution to a questionable problem. It combines instant use of iron sights, swinging out of the way on a hinge with complete detachability by unscrewing a double-threaded locking bar that forms the hinge. The latter needs to be tight enough to hold everything in place, and as a result is usually too tight to be readily removed.

At the other end of the scale is the German claw mount that operates in essentially the same way as Purdey underlugs on a double rifle. The scope can be removed instantly without conscious thought, and reinstalled almost as easily. It’s a snap action, so everything happens automatically. Its drawbacks are that it is expensive, difficult to install and does not accommodate a wide range of scope sizes and configurations. Though for certain applications – dangerous-game rifles especially – it is unbeatable.

Of course, eumatics is not an absolute. Some non-eu factory rifles can be modified to a state of “eu”-ness. Serious custom-rifle buyers, of the type who care about superb function rather than glitz, are looking for a rifle that is eumatic in all aspects of its operation. Sometimes this is accomplished but, alas, not always. It requires a gunmaker to execute instructions and who fully understands the goal.

Generally speaking, this is the reason for the popularity of certain actions for customizing, and the lack of popularity in others. A non-eu feature that cannot be altered is a serious drawback in a custom rifle and rules many actions out of the running. The Mosin-Nagant, to take an extreme example, is so rough and junky that nothing can be done about it. The average Mauser K98 is just the opposite, hence its popularity for building custom rifles.

Alas, Thomas’ work in promoting eumatics never went very far. It would not be a bad idea, however, for gunsmithing schools to devote a few lessons to it. It might prevent some of the more egregious non-eu features that pop up on guns from time to time.